Efficient SF6 gas processing tool

A technology of gas treatment and tools, which is applied in the direction of gas/liquid distribution and storage, equipment loaded into pressure vessels, container discharge methods, etc., which can solve the problems of increased equipment power outage time, decreased sealing degree, and easy wear and tear of gas pipe heads, etc. problems, to achieve the effect of saving manpower and material resources consumption, reducing the decrease of sealing degree, and shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

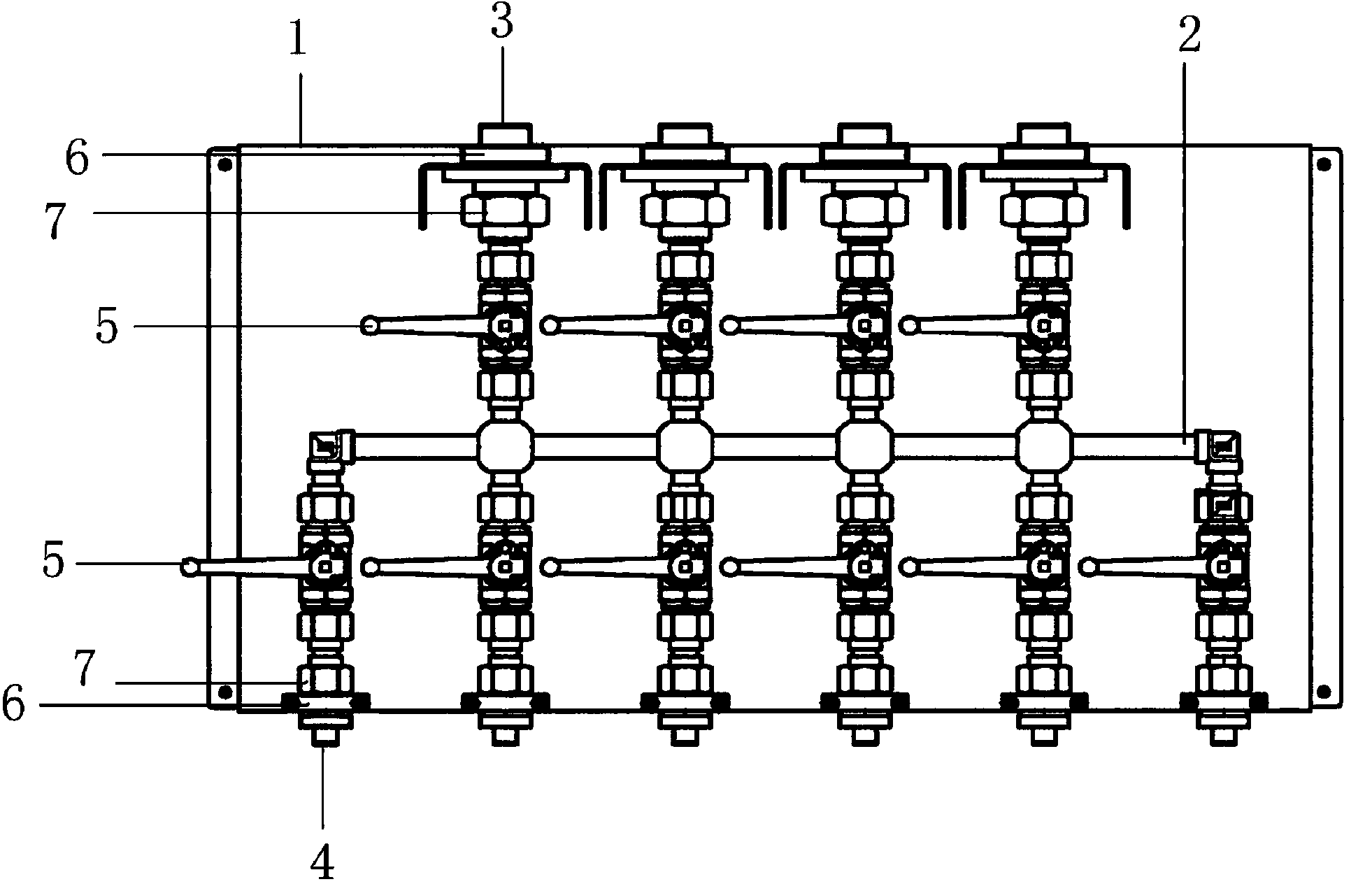

[0021] Such as figure 1 Shown, is a kind of high-efficiency SF6 gas processing tool of the present invention, and it comprises plate-shaped fixed base 1, the common connection pipe 2 that is installed on the fixed base 1 and at least 4 for connecting SF 6 For the joint of the equipment air chamber and the vacuum pump, the two pipe ends of the common connecting pipe 2 are closed, and at least 4 interfaces are arranged on the body of the common connecting pipe 2, and the joints are correspondingly connected to the interfaces.

[0022] In this embodiment, four DN40 copper joints 3 and six DN20 copper joints 4 are used for the joints. The internal diameter of the common connecting pipe 2 is DN40, and there are 10 interfaces, of which 4 interfaces are located on the body of the public connecting pipe 2. One side is used as DN40 interface, and the remaining 6 interfaces are located on the other side of the common connecting pipe 2 as DN20 interface. At the pipe end, the DN40 copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com