A laboratory sheet copying machine

A sheet copying machine and laboratory technology, applied in papermaking, papermaking machines, textiles and papermaking, etc., can solve the problems that the forming process of the top wire former and the sandwich former cannot be truly and effectively simulated, and achieve the solution of manual copying Difficult pattern, not easy to clog, improve the effect of distribution trend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

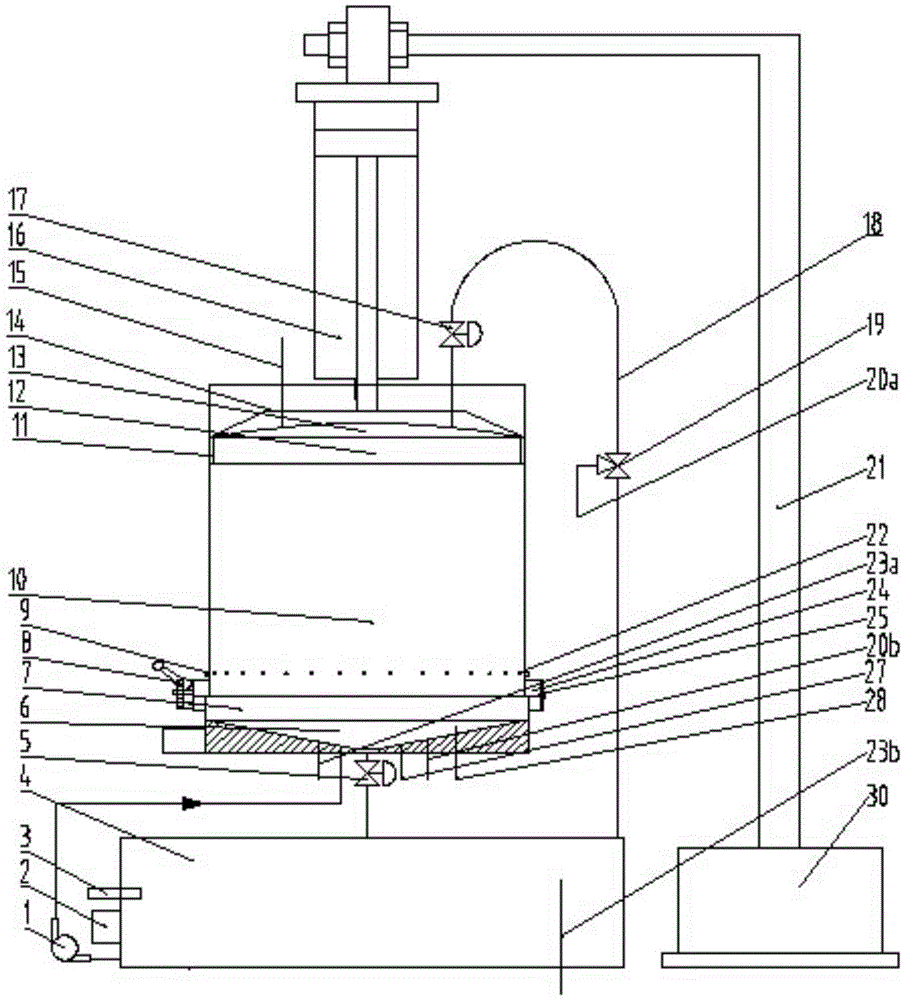

[0032] see figure 1 , the laboratory sheet copying device of the present invention comprises a pulp storage tank 10, the bottom of the pulp storage tank 10 is connected to the buffer tank 6, and the pulp storage tank 10 is sealed and docked with the buffer tank 6 through the ring disc 24 and the rubber ring 25, And a manual opening device 8 is provided at the joint, a lower filter device 7 is arranged in the buffer tank 6, the bottom of the buffer tank 6 and the white water tank 4 are connected by a pipeline provided with a bottom regulating valve 5, and the upper part of the slurry storage tank 10 has an upper Filter device 12, upper filter device 12 links to each other with cylinder 16, and cylinder 16 is fixed on the swing arm 21, and drives swing arm 21 to rotate with transmission device 30, has constituted the main part of laboratory sheet copying device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com