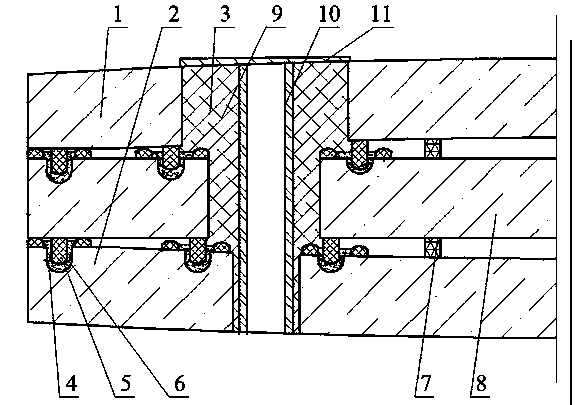

Metal-welded convex double-vacuum-layer glass with sealing strips, sealing grooves, and mounting hole.

A sealing strip groove, metal welding technology, applied in glass production, glass molding, glass re-molding and other directions, can solve the problems of weakening the air tightness of solder performance, feasibility effect, etc., to increase the sealing area and improve the life. , Conducive to the effect of vacuuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Embodiment: Referring to the accompanying drawings, the convex double vacuum laminated glass consists of an upper convex glass 1 , an intermediate glass 8 and a lower convex glass 2 . Its production method is as follows: First, cut three pieces of flat glass of the required size according to the shape and size of the vacuum glass to be produced, drill a through hole on the three pieces of glass to form the installation hole 3, and insert the middle glass 8 and the lower glass 2 Set up a sealing groove 6 on the periphery of the upper surface and the periphery of the installation hole 3, and carry out edge grinding, chamfering, cleaning and drying on the three pieces of glass; And the periphery of the sealing groove 6 is sprayed to prepare the sealing strips 5 and 6, and the support 7 is prepared by printing on the lower surface of the upper glass 1 and the upper surface of the lower glass 2, and the intermediate glass 8 is directly sent into a high-temperature furnace for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com