Automatic steamer filling machine

An automatic and retort technology, applied in the field of winemaking, can solve the problems of uniformity, different wine yield and wine quality, and inability to guarantee the sprinkling of materials from beginning to end, so as to achieve the effect of improving quality and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

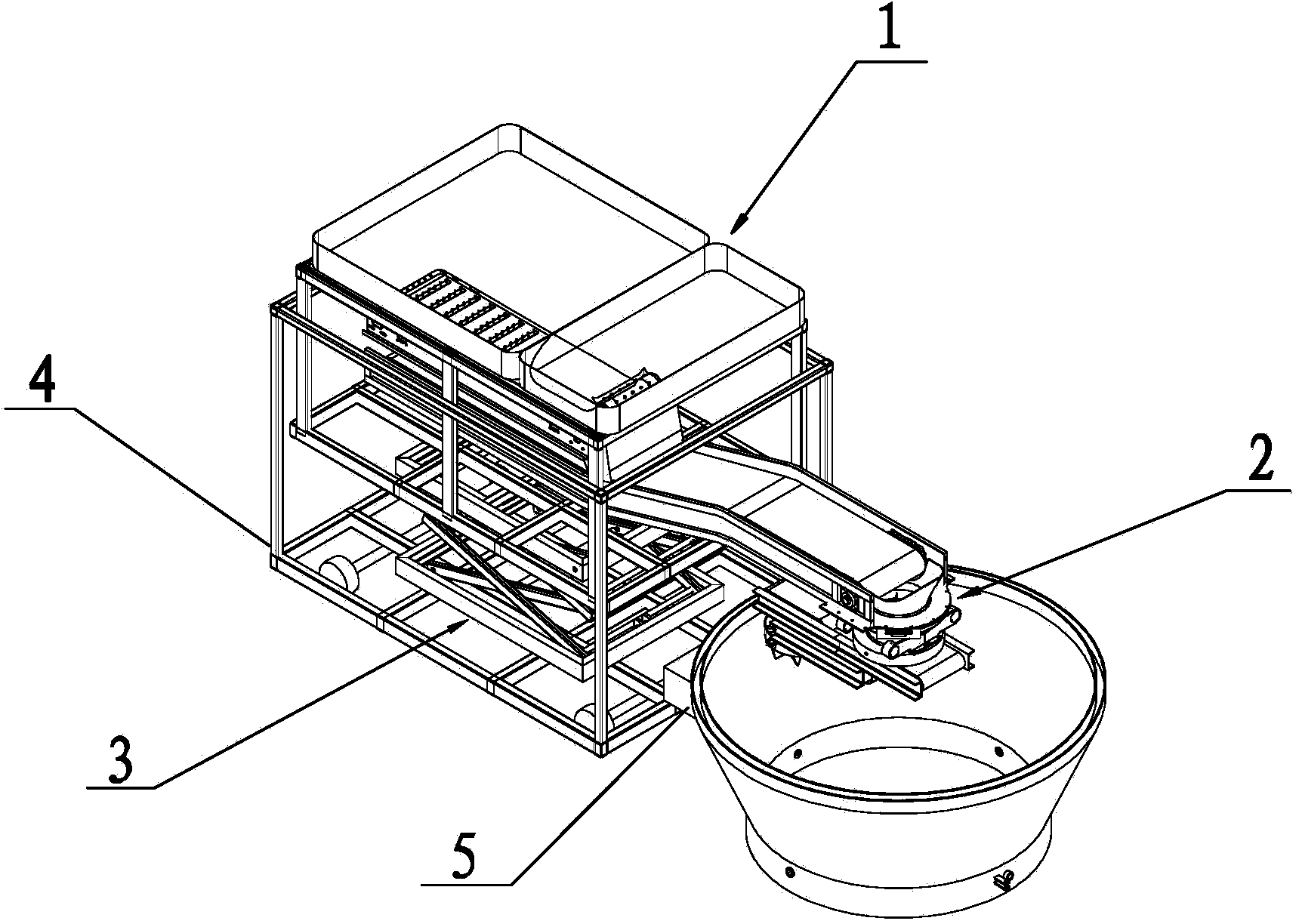

[0036] As shown in the figure, a kind of automatic steamer loading machine disclosed by the present invention includes a mixing and conveying device 1, a steamer spreading device 2, an elevator 3, and the elevator 3 and the mixing and conveying device 1 are arranged in a mobile frame 4, and the moving A horizontally movable retort bucket positioner 5 is arranged in the frame 4, and the retort bucket positioner 5 is provided with a groove corresponding to the edge of the retort bucket.

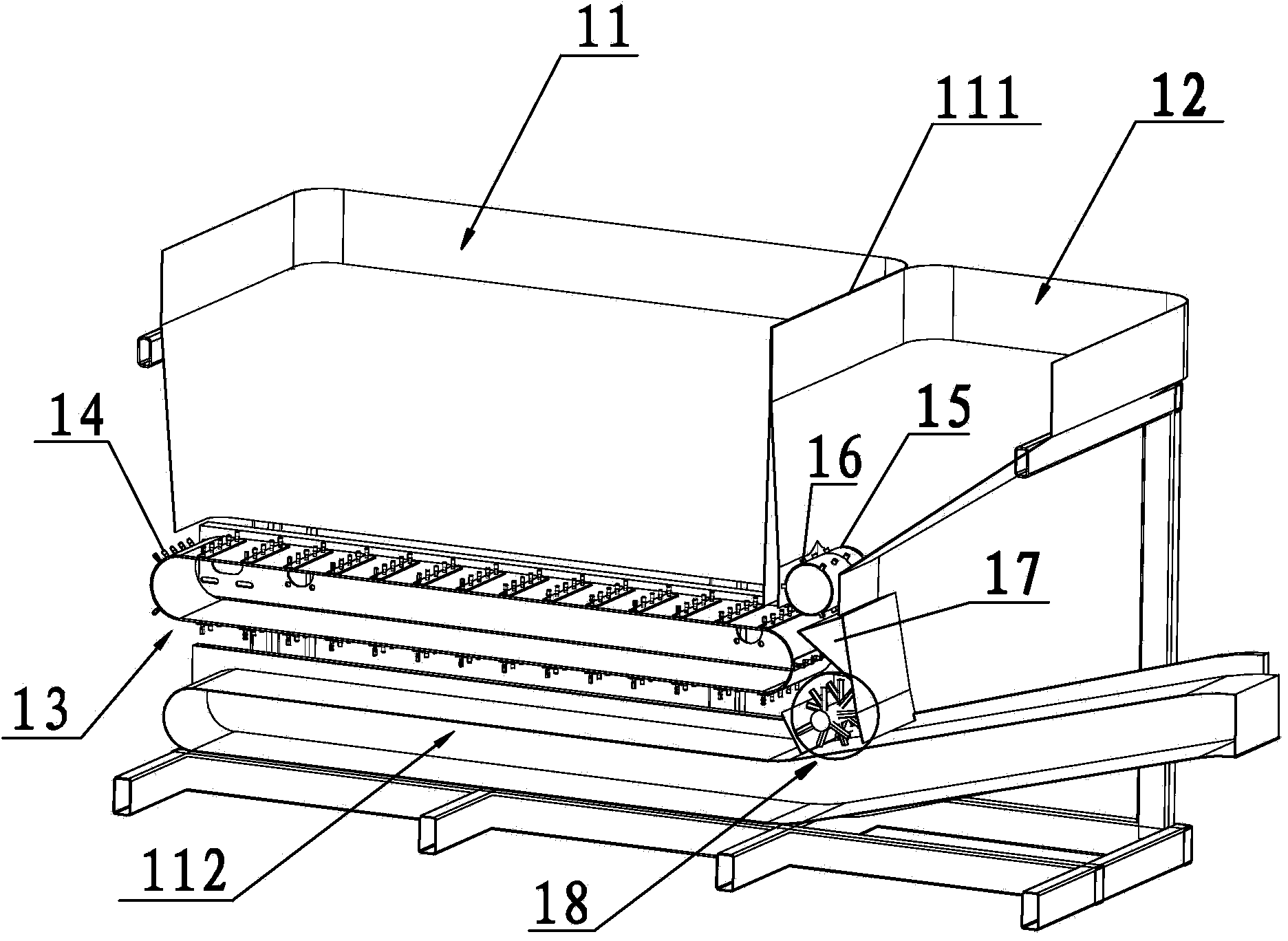

[0037] The mixing and conveying device 1 comprises a left feed port 11, a right feed port 12, an upper conveyor belt 13, a mixing chamber, and the left feed port 11 and the right feed port 12 are separated by a partition plate 111, and the left feed port Port 11 is used to transport the fermented grains, and the right inlet 12 is used to transport bran hulls (ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com