Method for maintaining porous concrete through carbon dioxide

A porous concrete and carbon dioxide technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of high energy consumption of steam curing, long curing cycle, and high energy consumption of concrete, achieve rapid strength development, low porosity, and curb the greenhouse effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment includes the following steps:

[0023] (1) Mixed molding of concrete: the coarse aggregate is crushed stone, the specimen is pressed and molded, and the molding pressure is 16Mpa, and the initial concrete embryo is obtained;

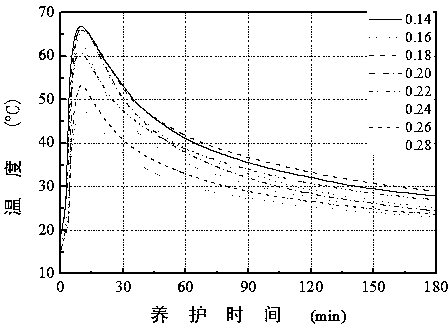

[0024] (2) Put the initial concrete body obtained in step (1) into the pre-curing device for pre-curing. The pre-curing temperature is 25°C, the relative humidity is 60%, and the blower is used to circulate the air. The pre-curing time is 10 hours;

[0025] (3) When the pre-cured mixture embryo reaches the predetermined remaining water-cement ratio of 0.35, put CO 2 In the curing container, vacuumize, the vacuum time is 5min, the maximum negative pressure is 0.05MPa, and keep at the maximum negative pressure for 5min; 2 gas for CO 2 For curing, the volume concentration of carbon dioxide gas is 60%, and the curing time for carbon dioxide is 3 hours. After the curing is completed, the gas is released and the curing is stopped.

[...

Embodiment 2

[0030] This embodiment includes the following steps:

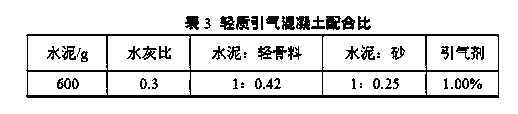

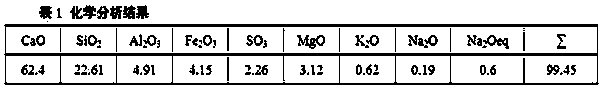

[0031] (1) Mixed molding of concrete: the bulk density of the porous concrete block is set at 1200kg / m 3 , the foaming agent dosage is 2.5%; the concrete is prepared according to the mixing ratio of 0.28 and 0.35 respectively for the water-cement ratio, and the mixing mechanism is selected for 6 minutes; Embryo;

[0032] (2) Put the initial concrete body obtained in step (1) into the pre-curing device for pre-curing. The pre-curing temperature is 20°C, the relative humidity is 50%, and the fan is used to circulate the air. The pre-curing time is 6 hours;

[0033] Make the remaining water-cement ratio 0.05-0.35;

[0034] (3) When the pre-cured mixture embryo reaches the predetermined remaining water-cement ratio, put CO 2 In the curing container, evacuate for 10 minutes, evacuate to -0.09MPa, and keep it at the maximum negative pressure for 5 minutes; then introduce CO 2 gas for CO 2 For curing, the volume concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com