Device loaded with structured catalyst with radial wall flow

A structured catalyst and radial wall technology, applied in the direction of chemical/physical processes, chemical instruments and methods, etc., can solve the problem of catalyst carbon deposition deactivation, dealumination deactivation, affecting product quality stability, poor heat transfer of catalyst bed, etc. problems, to achieve the effect of low manufacturing difficulty, small inter-individual differences, and good axial uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

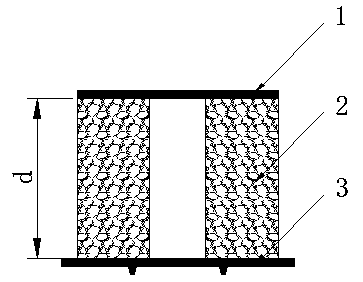

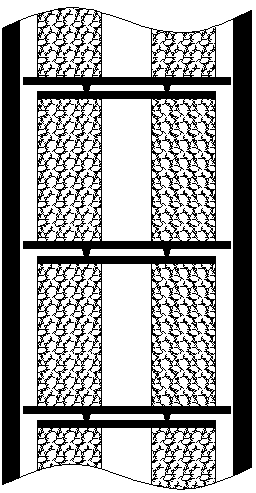

[0030] Such as figure 1 As shown, the structured catalyst unit with radial wall flow of the present invention includes: a structured carrier loaded with catalyst, a reactant flow wall flow guide panel and an expansion ring with thermal expansion and cold contraction effects.

[0031] The structural carrier loaded with the catalyst in the structured catalyst unit with radial wall flow is a hollow cylindrical silicon carbide foam, the hollow part of which is coaxial with the main body of the silicon carbide foam structure and its cross section is circular. The foam silicon carbide cylinder is 20 mm long, 23 mm in outer diameter, and 5 mm in diameter of the hollow cylinder. In situ growth of ZSM-5 zeolite on the surface of foamed silicon carbide carrier.

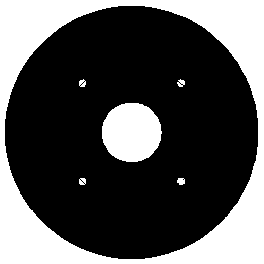

[0032] The top of the catalyst-loaded structured carrier is equipped with a reactant wall flow guide panel, which is a dense silicon carbide material. The panel is a solid cylinder coaxial with the catalyst-loaded structured...

Embodiment 2

[0037] Such as figure 1 As shown, the structured catalyst unit with radial wall flow of the present invention includes: a structured carrier loaded with catalyst, a reactant flow wall flow guide panel and an expansion ring with thermal expansion and cold contraction effects.

[0038] The structural carrier loaded with the catalyst in the structured catalyst unit with radial wall flow is a hollow cylindrical silicon carbide foam, the hollow part of which is coaxial with the main body of the silicon carbide foam structure and its cross section is circular. The foamed silicon carbide cylinder is 40 mm long, 22 mm in outer diameter, and its hollow cylindrical surface is 7 mm in diameter. In situ growth of ZSM-5 zeolite on the surface of foamed silicon carbide carrier.

[0039] The top of the catalyst-loaded structured carrier is equipped with a reactant wall flow guide panel, which is a dense silicon carbide material. The panel is a solid cylinder coaxial with the catalyst-load...

Embodiment 3

[0044] Such as figure 1 As shown, the structured catalyst unit with radial wall flow of the present invention includes: a structured carrier loaded with catalyst, a reactant flow wall flow guide panel and an expansion ring with thermal expansion and cold contraction effects.

[0045] The structural carrier loaded with the catalyst in the structured catalyst unit with radial wall flow is a hollow cylindrical silicon carbide foam, the hollow part of which is coaxial with the main body of the silicon carbide foam structure and its cross section is a regular hexagon. The foam silicon carbide cylinder is 200 mm long, 20 mm in outer diameter, and 18 mm in diameter of the hollow cylinder. In situ growth of ZSM-5 zeolite on the surface of foamed silicon carbide carrier.

[0046] The top of the catalyst-loaded structured carrier is equipped with a reactant wall flow guide panel, which is a dense silicon carbide material. The panel is a solid cylinder coaxial with the catalyst-loaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com