Water pan and air energy water heater with same

An air-energy water heater and water-receiving pan technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of poor drainage, difficult drainage, and the inability of the heat pump to operate reliably, and achieve the effect of draining condensate water well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

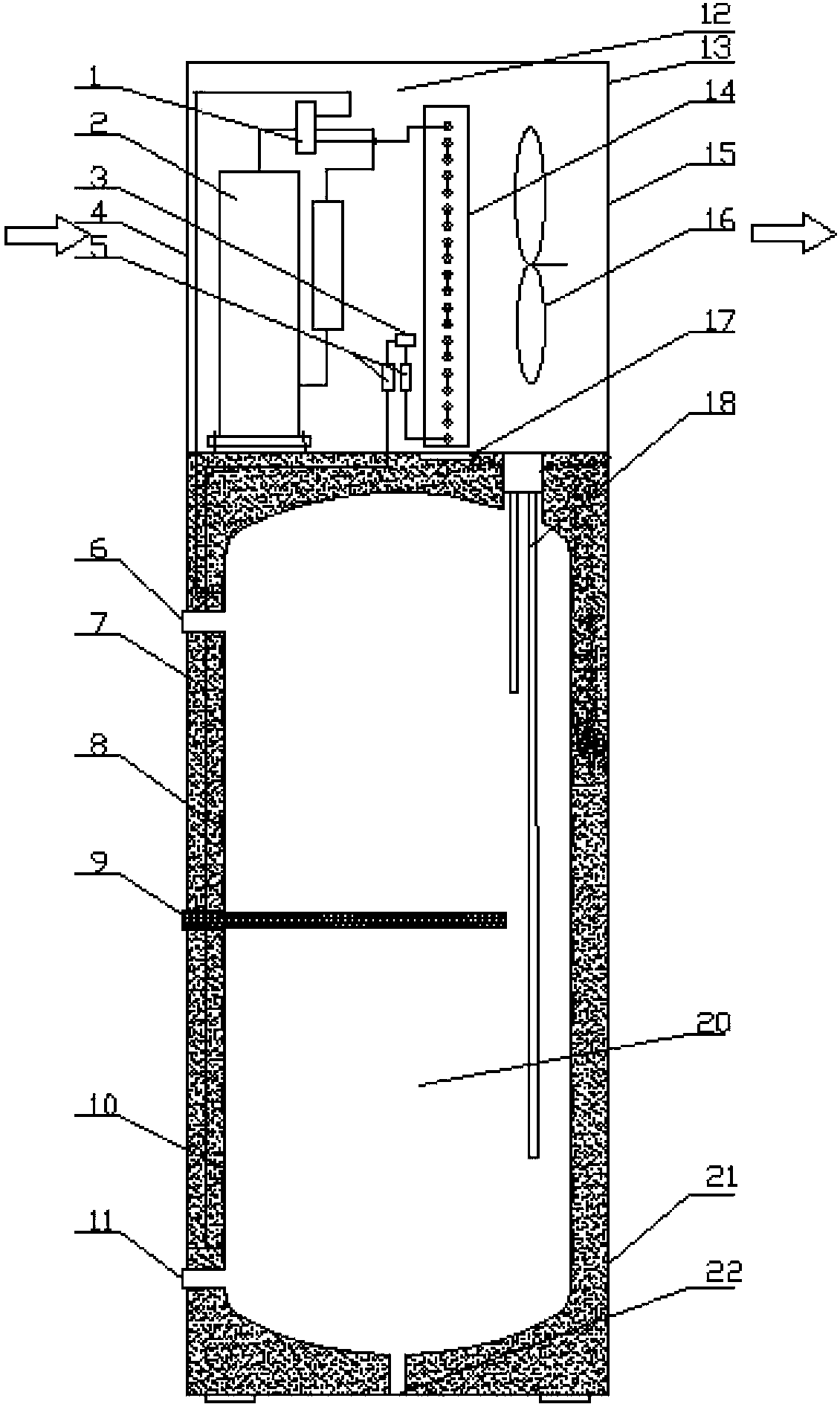

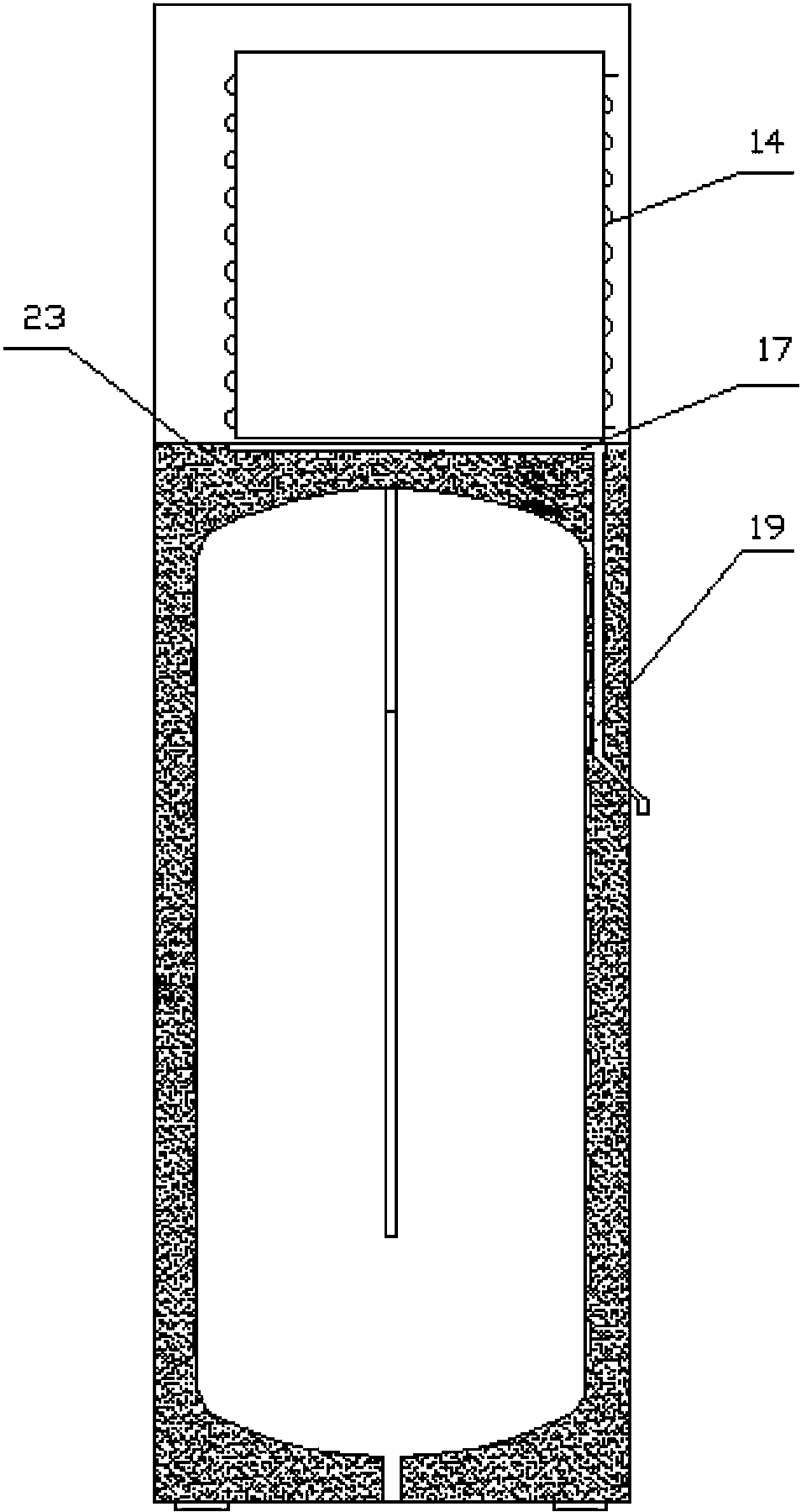

[0024] Taking the integral air energy water heater as an example, the present invention provides the first embodiment of the integral air energy water heater, for details, refer to figure 1 , figure 2 , the integrated air energy water heater of the present invention includes an external machine part 12 and a water tank part 20, and the external machine part 12 includes a working medium reversing element 1, a compressor 2, a throttling element 3, an air inlet 4, and a filter 5, Outer cover 13, external machine heat exchanger 14, air outlet 15, fan system 16, water receiving tray 17. The water tank component 20 includes a water outlet 6, an insulation layer 7, a water tank heat exchanger 8, a magnesium rod 9, an inner tank 10, a water inlet 11, a temperature sensing package 18, a drain pipe 19, a casing 21, a sewage outlet 22, and a chassis 23 .

[0025] Preferably, the water receiving tray 17 includes a water receiving surface and a bottom surface, and the water receiving su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com