Functional yellow rice wine and preparation method thereof

A functional, rice wine technology, applied in the preparation of alcoholic beverages, biochemical equipment and methods, microorganism-based methods, etc., can solve the problems of low nutrient content, difficult preservation, high cost, and achieve good taste and low alcohol content. , the effect of regulating blood lipids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of functional yellow rice wine of the present invention can enumerate: the method for adding orange peel, pectinase and naringinase in the yellow rice wine fermentation process; and the method of adding the hydrolysis fermentation liquid containing the above-mentioned pectin degradation products and the above-mentioned bioflavonoids in the rice wine blending process, etc. However, the present invention is not limited by these methods.

[0029] Wherein, regarding the method of adding orange peel, pectinase and naringinase in the yellow rice wine fermentation process, can enumerate following method 1 and method 2.

[0030]Regarding method 1, it includes: (1) using at least one kind of koji selected from yeast, Aspergillus oryzae and Aspergillus niger to carry out the main fermentation of the fermentation raw materials, (2) adding orange peel, pectinase and Naringinase, carry out re-fermentation, (3) inactivate the enzyme and age to obtain the above...

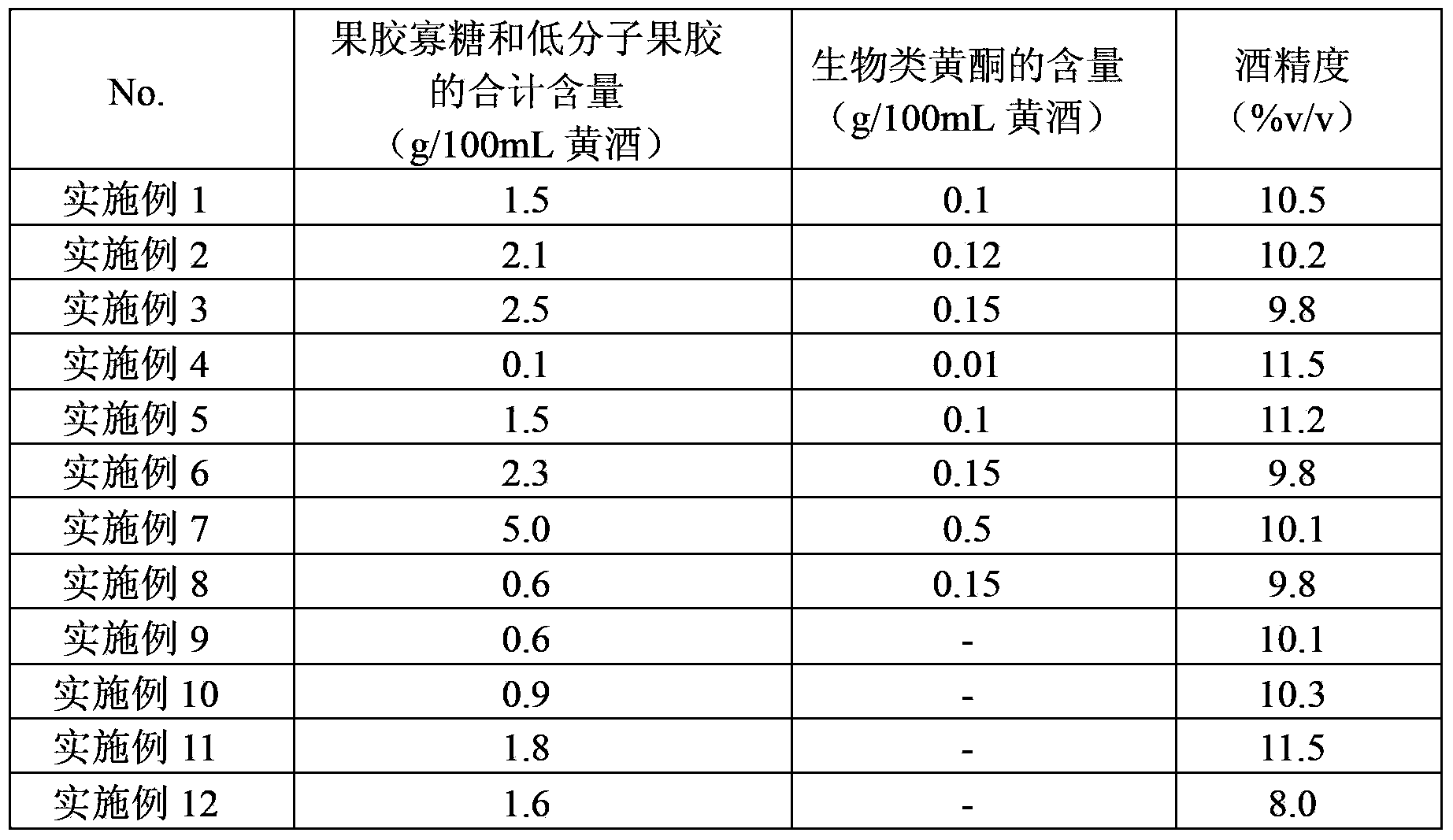

Embodiment 1

[0046] After soaking 100g rice, add 150mL water, add 6% koji (mass ratio, the same below) made by Aspergillus oryzae (Huniang 336) and 0.1% active dry yeast (Anqi rice wine active dry yeast) to ferment. Add 10g of orange peel, 0.5g of pectinase (Tianjin Lihua Enzyme Technology Co., Ltd., 30000U / g) and 1g of naringinase (Zhejiang Taikang Biotechnology Co., Ltd., Zhejiang Taikang Biotechnology Co., Ltd., with an enzyme activity of 20000U / g) in 4 days. g) Under the condition of 25-30°C, further ferment for 3 days, and age at 85°C for 15 minutes to inactivate enzymes to obtain the finished rice wine, which has clear and transparent color, elegant and fragrant wine aroma, and mellow and comfortable taste. In 100mL of the obtained rice wine, the total content of pectin oligosaccharides with a weight average molecular weight of 400-5000 and low molecular weight pectin with a weight average molecular weight of more than 5000 and less than or equal to 10000 is about 1.5g, and the conten...

Embodiment 2

[0048] Soak 100g rice, add 150mL water, add Aspergillus oryzae (Shanghai Niang 336) to make koji 4%, Aspergillus niger (Shanghai Niang 336) to make koji 2% and 0.1% active dry yeast (Anqi rice wine active dry yeast) to ferment 15g orange peel, 0.8g acid pectinase (Tianjin Lihua Enzyme Preparation Technology Co., Ltd., 30000U / g), 1g naringinase (Zhejiang Taikang Biotechnology Co., Ltd., enzyme activity 20000U / g) were added on the 4th day of main fermentation g) Under the condition of 25-30°C, ferment for another 2 days, inactivate the enzyme, and age to obtain the finished rice wine, which has clear and transparent color, elegant and fragrant wine aroma, and mellow and comfortable taste. In 100mL of the obtained rice wine, the total content of pectin oligosaccharides with a weight average molecular weight of 400-5000 and low molecular weight pectin with a weight average molecular weight of more than 5000 and less than or equal to 10000 is about 2.1g, and the content of bioflavon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com