Europium and terbium-co-doped vanadite luminescent thin film and preparation method and application thereof

A vanadite, light-emitting thin film technology, used in light-emitting materials, chemical instruments and methods, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The method for preparing the above-mentioned europium-terbium co-doped vanadite luminescent film includes the following steps:

[0015] S11, according to Me 3 (VO 4 ) 2 : XEu 3+ ,yTb 3+ The stoichiometric ratio of each element is called MeO, V 2 O 5 , Eu 2 O 3 And Tb 4 O 7 The powder is mixed uniformly and sintered at 900℃~1300℃ to make the target material.

[0016] x is 0.01 to 0.05, y is 0.01 to 0.04, and Me is Mg, Ca, Sr or Ba.

[0017] In S11, preferably, MeO, V 2 O 5 , Eu 2 O 3 , And Tb 4 O 7 The powder is mixed uniformly and sintered at 1250℃ to make a ceramic target of Ф50mm×2mm.

[0018] S12. After the substrate is provided and the substrate is preprocessed, the target and substrate obtained in S11 are loaded into the vacuum chamber of the magnetron sputtering coating equipment, and adjusted to 1.0×10 -3 Pa~1.0×10 -5 Pa.

[0019] The operation of preprocessing the substrate may be: ultrasonically cleaning the substrate with acetone, absolute ethanol and deionized water in...

Embodiment 1

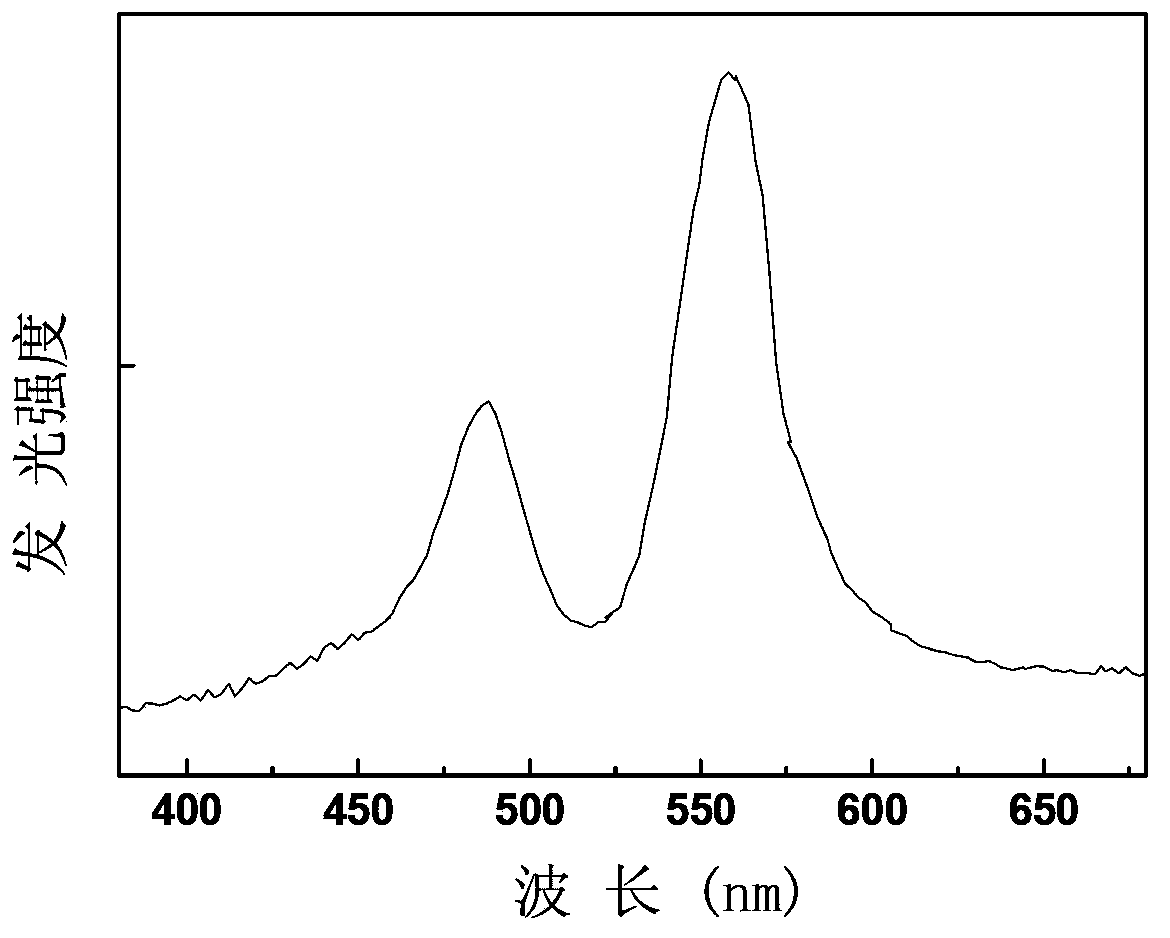

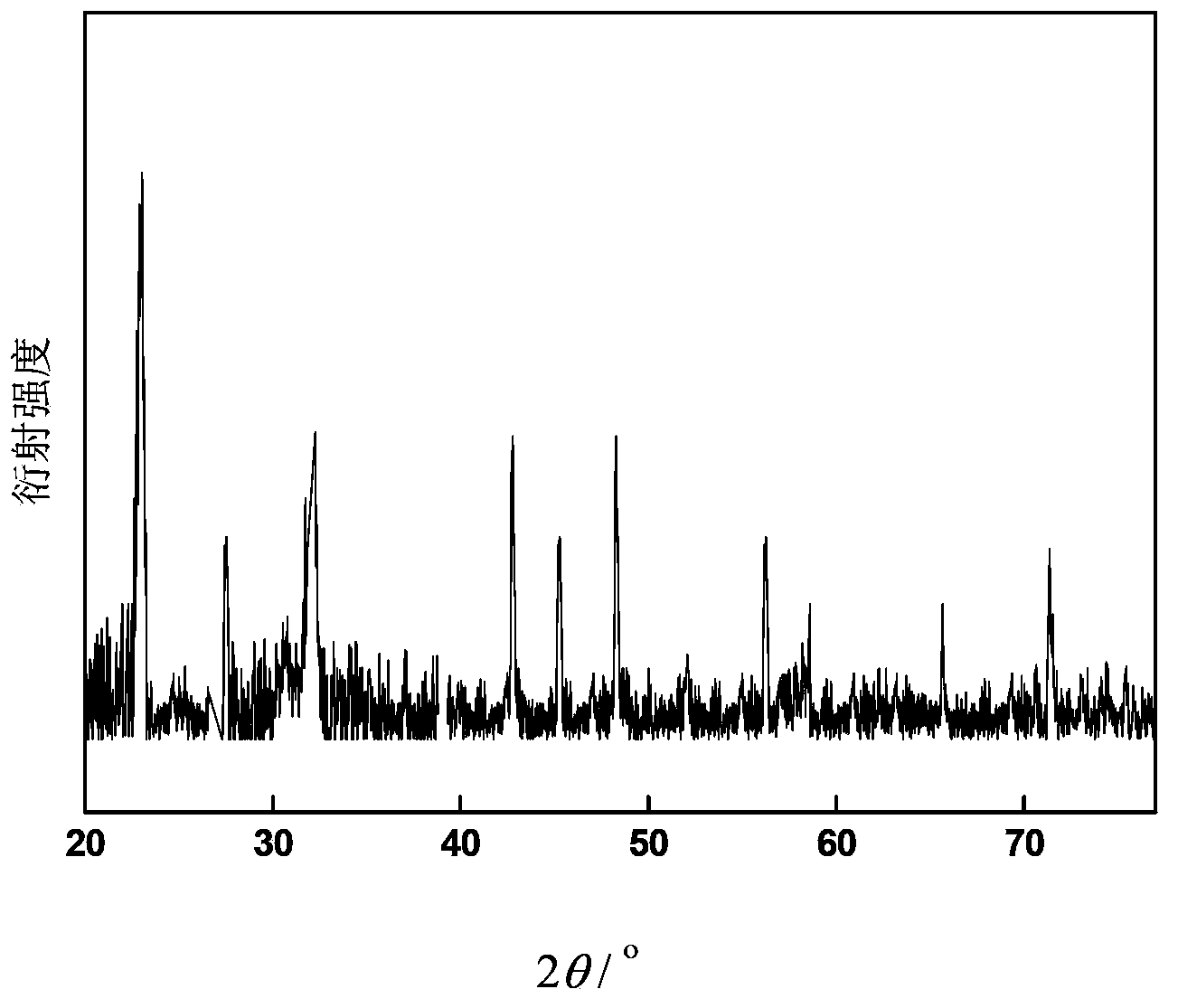

[0054] According to the molar amount of 3mmol, 1mmol, 0.015mmol, 0.005mmol, choose MgO, V 2 O 5 , Eu 2 O 3 And Tb 4 O 7 After the powder is uniformly mixed, it is sintered into a ceramic target of Ф50mm×2mm at 1250°C, and the target is put into a vacuum chamber. The glass substrate with ITO was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, and treated with oxygen plasma, and put into a vacuum chamber. Set the distance between the target and the substrate to 60 mm. Use mechanical pump and molecular pump to pump the vacuum of the cavity to 5.0×10 -4 Pa, the working flow of argon is 25sccm, the pressure is adjusted to 2.0Pa, the substrate temperature is 500°C, and the power of the magnetron sputtering coating equipment is 180W. By controlling the magnetron sputtering time to 20min, the chemical formula with a thickness of 220nm is Mg 3 (VO 4 ) 2 : 0.03Eu 3+ ,0.02Tb 3+ The europium and terbium co-doped vanadite luminescent thin film was the...

Embodiment 2

[0058] According to the molar amount of 3mmol, 1mmol, 0.005mmol, 0.0025mmol, choose MgO, V 2 O 5 , Eu 2 O 3 And Tb 4 O 7 After the powder is uniformly mixed, it is sintered into a ceramic target of Ф50mm×2mm at 900°C, and the target is put into a vacuum chamber. The glass substrate with ITO was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, and treated with oxygen plasma, and put into a vacuum chamber. Set the distance between the target and the substrate to 45 mm. Use mechanical pump and molecular pump to pump the vacuum of the cavity to 1.0×10 -3 Pa, the working flow of argon is 10sccm, the pressure is adjusted to 0.2Pa, the substrate temperature is 250℃, the power of the magnetron sputtering coating equipment is 60W, and the magnetron sputtering time is 10min to obtain a thickness of 60nm The chemical formula is Mg 3 (VO 4 ) 2 :0.01Eu 3+ ,0.01Tb 3+ The europium and terbium co-doped vanadite luminescent thin film was then annealed in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com