Rare earth type hydrotalcite composite heat stabilizer and heat-stable polyvinyl chloride

A composite thermal stabilizer and hydrotalcite technology, which is applied in the field of rare earth hydrotalcite composite thermal stabilizers and thermally stable polyvinyl chloride, can solve the problems of general thermal stability of ternary and binary hydrotalcites, and achieve thermal stability Good properties, good synergistic effect, and the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

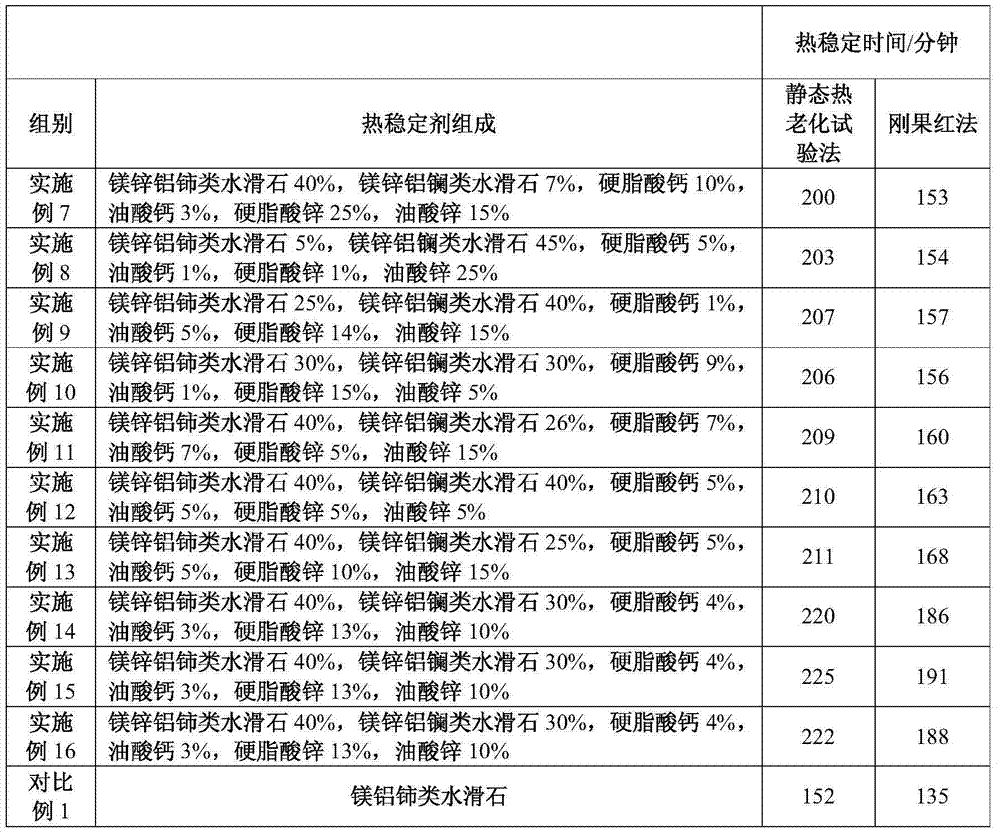

Examples

preparation example Construction

[0034] The preparation method of the modified magnesium-zinc-aluminum-cerium hydrotalcite and the modified magnesium-zinc-aluminum-lanthanum hydrotalcite comprises the following steps:

[0035] 1) Divalent magnesium source compound, divalent zinc source compound, trivalent aluminum source compound and trivalent rare earth compound according to M 2+ / M 3+ = 2:1 ~ 4:1 molar ratio dubbed mixed solution, M 3+ The concentration of Zn is 0.2~2.0mol / L, in terms of molar ratio, Zn 2+ / M 2+ = 0.1 ~ 0.8, RE 3+ / M 3+ =0.02~0.8, where RE 3+ for Ce 3+ or La 3+ ,M 3+ Al in the mixed solution 3+ and RE 3+ ,M 2+ Zn in the mixed solution 2+ and Mg 2+ .

[0036] 2) Sodium carbonate and sodium hydroxide are made into an alkaline solution, in which CO 3 2- and M 3+ The molar ratio of NaOH is 0.5 ~ 3, the molar weight of NaOH and M 2+ and M 3+ The ratio of the total molar weight is 0.5-5.

[0037] 3) Add the mixed solution and alkaline solution into deionized water and stir for...

Embodiment 1

[0050] Magnesium zinc aluminum cerium hydrotalcite (molar ratio: M 2+ / M 3+ =2:1, Zn 2+ / M 2+ =0.5, Ce 3+ / M 3+ =0.025, n(CO 3 2- ) / n(M 3+ )=0.50, n(NaOH) / n(M 2+ +M 3+ )=2.5) preparation and modification

[0051] Weigh 4.860g Mg(NO 3 ) 2 ·6H 2 O (0.025moL), 7.437g Zn (NO 3 ) 2 ·6H 2 O (0.025moL), 6.027g Al (NO 3 ) 3 9H 2 O (0.024moL), 0.271g Ce (NO3 ) 3 ·6H 2 O (0.000625moL), add 40mL deionized water after mixing; weigh 1.304gNa 2 CO 3 (0.0123moL) and 7.5gNaOH (0.19moL), after mixing, add 40mL of deionized water; add the above two solutions dropwise to 30mL of deionized water, keep the pH value between 11 and 12, and stir the reaction at 65°C After the dropwise addition, continue to stir for 2 hours, then age at 45° C. for 4 hours, filter, and wash to PH=7 to obtain a magnesium-zinc-aluminum-cerium hydrotalcite filter cake (wet cake moisture content is about 50%). Add water in wet filter cake, water / wet filter cake mass ratio is 20: 1, be warming up to 6...

Embodiment 2

[0053] Magnesium zinc aluminum cerium hydrotalcite (molar ratio: M 2+ / M 3+ =2:1, Zn 2+ / M 2+ =0.5, Ce 3+ / M 3+ =0.05, n(CO 3 2- ) / n(M 3+ )=0.50, n(NaOH) / n(M 2+ +M 3+ )=2.5) preparation and modification

[0054] Weigh 6.160g MgSO 4 ·7H 2 O (0.025moL), 7.189g ZnSO 4 ·7H 2 O (0.025moL), 8.120gAl 2 (SO 4 ) 3 18H 2 O (0.012moL), 0.542g Ce (NO 3 ) 3 ·6H 2 O (0.00125moL), add 40mL deionized water after mixing; weigh 1.335gNa 2 CO 3 (0.0126moL) and 7.5gNaOH (0.19moL), after mixing, add 40mL of deionized water; add the above two solutions dropwise to 30mL of deionized water, keep the pH value between 11 and 12, and stir the reaction at 85°C After the dropwise addition, continue to stir for 2 hours, then age at 65° C. for 20 hours, filter, and wash to PH=7 to obtain a magnesium-zinc-aluminum-cerium hydrotalcite filter cake (the moisture content of the wet filter cake is about 80%). Add water in wet filter cake, water / wet filter cake mass ratio is 50: 1, be warmin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com