Process for the production of narrowly distributed low molecular weight polymers

A low-molecular-weight, production-method technology, applied in the production of narrow-distribution low-molecular-weight polymers, in the field of polymer production, can solve the problems of difficulty in amplification, long material circulation reaction time, long pipelines, etc., to achieve uniform product quality and production process. The effect of continuous reaction and compact process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1. the production of polyacrylic acid (viscosity-average molecular weight M w 11194)

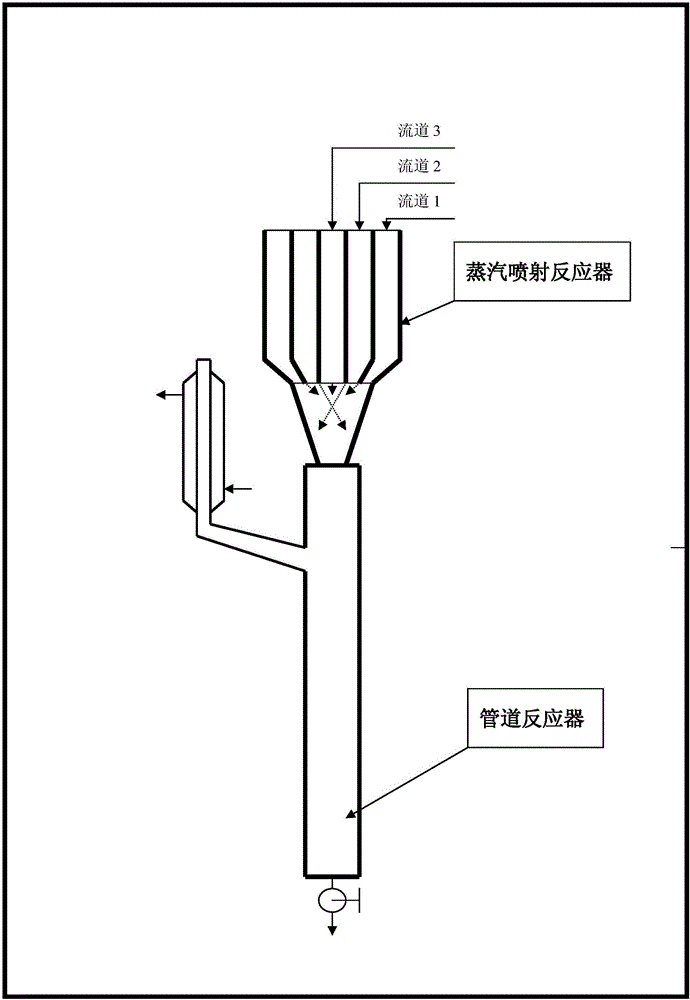

[0048] The ratio of water, acrylic acid, sodium hypophosphite is 25 / 50 / 1. Pump into the middle flow channel 1 of the steam jet reactor at a speed of 4.95kg / h, the ratio of ammonium persulfate and water is 1 / 13, pump it into the flow channel 3 at a speed of 1.37kg / h, and the steam enters through the flow channel 2 , control steam pressure 0.2mPa, mist temperature 90°C, mist flows into the pipeline reactor to continue the reaction, the reaction product flows out from the lower end of the pipeline, and the residence time is controlled for 30 minutes. Product viscosity average molecular weight M w 11194, number average molecular weight M n 6909, distribution coefficient 1.62, solid content 47%, residual acrylic acid monomer <0.5%.

Embodiment 2

[0049] Embodiment 2. the production of polyacrylic acid (viscosity-average molecular weight M w 6031)

[0050] Change the ratio of water, acrylic acid, and sodium hypophosphite to 12 / 25 / 1. Other conditions are with embodiment 1.

[0051] The viscosity-average molecular weight M of the resulting product polyacrylic acid w 6031, number average molecular weight M n 3950, distribution coefficient 1.53, solid content 47%.

Embodiment 3

[0052] Embodiment 3. the production of polyacrylic acid (viscosity-average molecular weight M w 4342)

[0053] Change the ratio of water, acrylic acid, and sodium hypophosphite to 8 / 16.7 / 1. Other conditions are with embodiment 1. The M of the obtained product polyacrylic acid w 4642.M n 2817, distribution coefficient 1.54, solid content 47%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| distribution coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com