Continuous pretreatment method of maleic anhydride emulsifying waste water

A technology for emulsification of wastewater and maleic anhydride, applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., can solve the problems of increased energy consumption, complex process and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

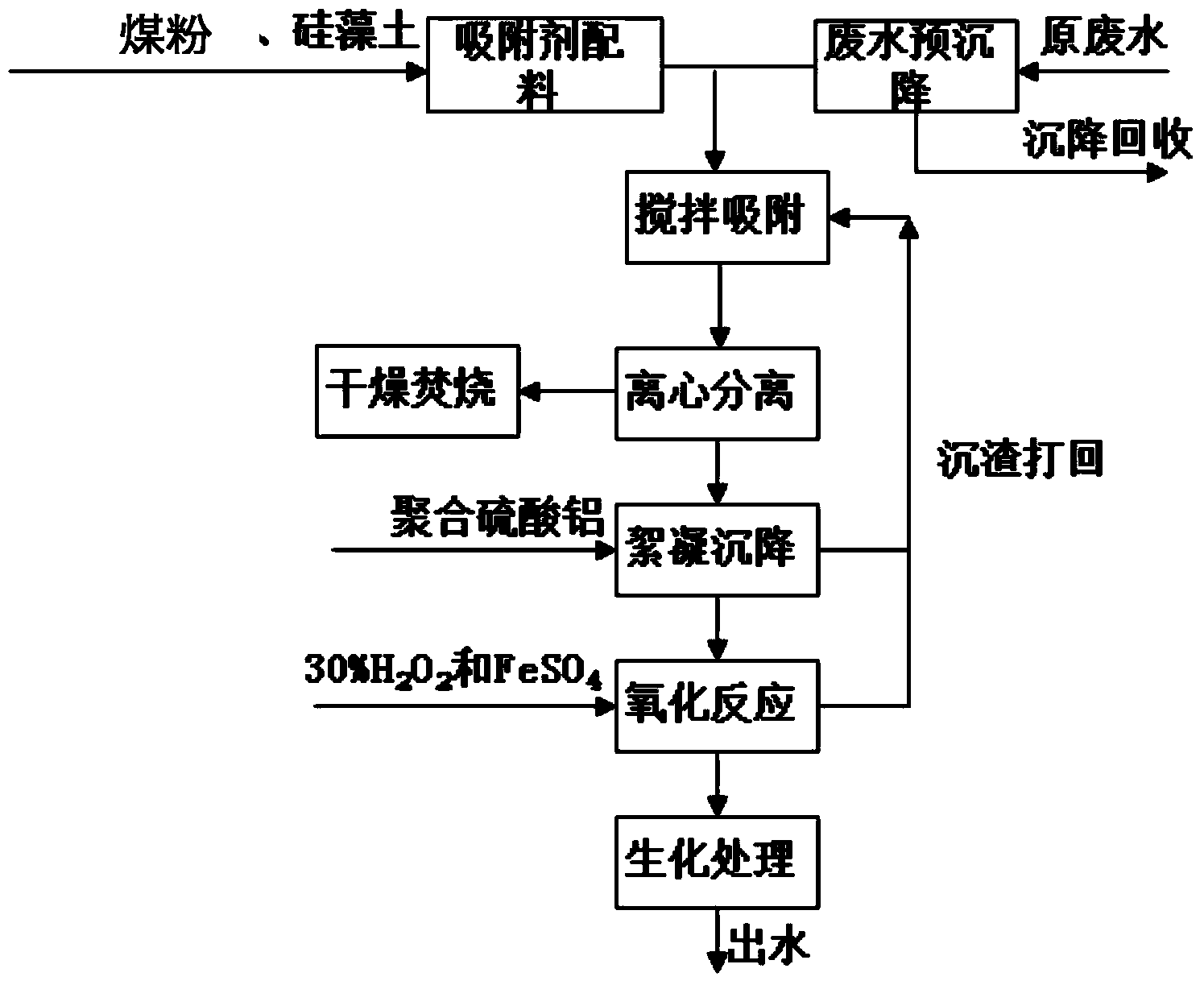

Method used

Image

Examples

Embodiment 1

[0034] Preparation of the adsorbent:

[0035] The lignite is ground by a coal mill to obtain coal powder with a particle size of 15-30 μm. The raw material of diatomite is dried at 120°C and pulverized by high-pressure airflow. Coal powder and diatomaceous earth are ground and mixed according to the mass ratio of 9:1 to obtain the adsorbent.

[0036] Wastewater treatment process:

[0037] The COD 9500 in the supernatant liquid I obtained after the maleic anhydride emulsified wastewater was settled in the settling tank, the content of dibutyl phthalate was 0.15% (wt), and the supernatant liquid I was continuously added to the stirring adsorption tank at 500kg / h, and the adsorption The agent is continuously added into the stirring adsorption tank at a rate of 10kg / h through a feeder, and the residence time is controlled at 20min to obtain a mixed slurry. After the mixed slurry is separated by a solid-liquid separator, the separated solid is dried and incinerated. Add polyalu...

Embodiment 2

[0039] Preparation of the adsorbent:

[0040] The lignite is ground by a coal mill to obtain coal powder with a particle size of 15-30 μm. The raw material of diatomite is dried at 120°C and pulverized by high-pressure airflow. Coal powder and diatomaceous earth are ground and mixed in a mass ratio of 9:1.

[0041]Wastewater treatment process:

[0042] After the maleic anhydride emulsified wastewater settles in the settling tank, the COD is 16300, and the dibutyl phthalate content is 0.78% (wt). It is continuously added to the stirring adsorption tank at 500kg / h, and the adsorbent is continuously added at a speed of 40kg / h through the feeder. In the stirred adsorption tank, the residence time is controlled at 20min. The mixed slurry is separated by a solid-liquid separator for solid-liquid separation. After the mixed slurry is separated by a solid-liquid separator, the separated solid is dried and incinerated. Add polyaluminum sulfate to the obtained supernatant II, and th...

Embodiment 3

[0044] Preparation of the adsorbent:

[0045] The lignite is ground by a coal mill to obtain coal powder with a particle size of 1-15 μm. The raw material of diatomite is dried at 120°C and pulverized by high-pressure airflow. Coal powder and diatomaceous earth are ground and mixed in a mass ratio of 9:1.

[0046] Wastewater treatment process:

[0047] After the maleic anhydride emulsified wastewater settles in the settling tank, the COD is 16300, and the dibutyl phthalate content is 0.78% (wt). It is continuously added to the stirring adsorption tank at 500kg / h, and the adsorbent is continuously added at a speed of 40kg / h through the feeder. In the stirred adsorption tank, the residence time is controlled at 20min. The mixed slurry is separated by a solid-liquid separator for solid-liquid separation, and the separated solid is dried and incinerated. Add polyaluminum sulfate to the obtained supernatant II, and the feeding rate is 5g / h (the total amount of flocculant added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com