Strengthening synchronous water intake and drainage sbr sewage treatment process technology

A technology for sewage treatment and water inflow, applied in the field of sewage biological treatment technology, can solve the problems of high requirements for automatic control, high requirements for decanters, waste of water head loss, etc., to avoid daily maintenance, reduce drainage head loss, and improve utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Operation mode: through the automatic control system, the SBR reaction pool operates in the following order.

[0016] 1. Water intake and drainage process:

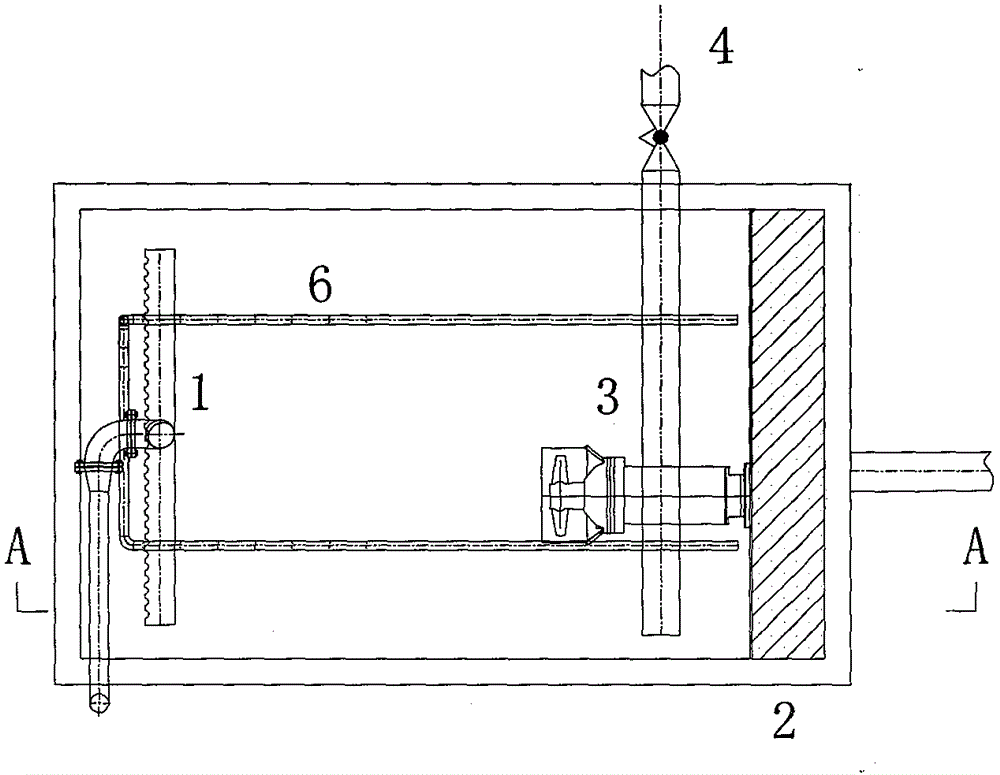

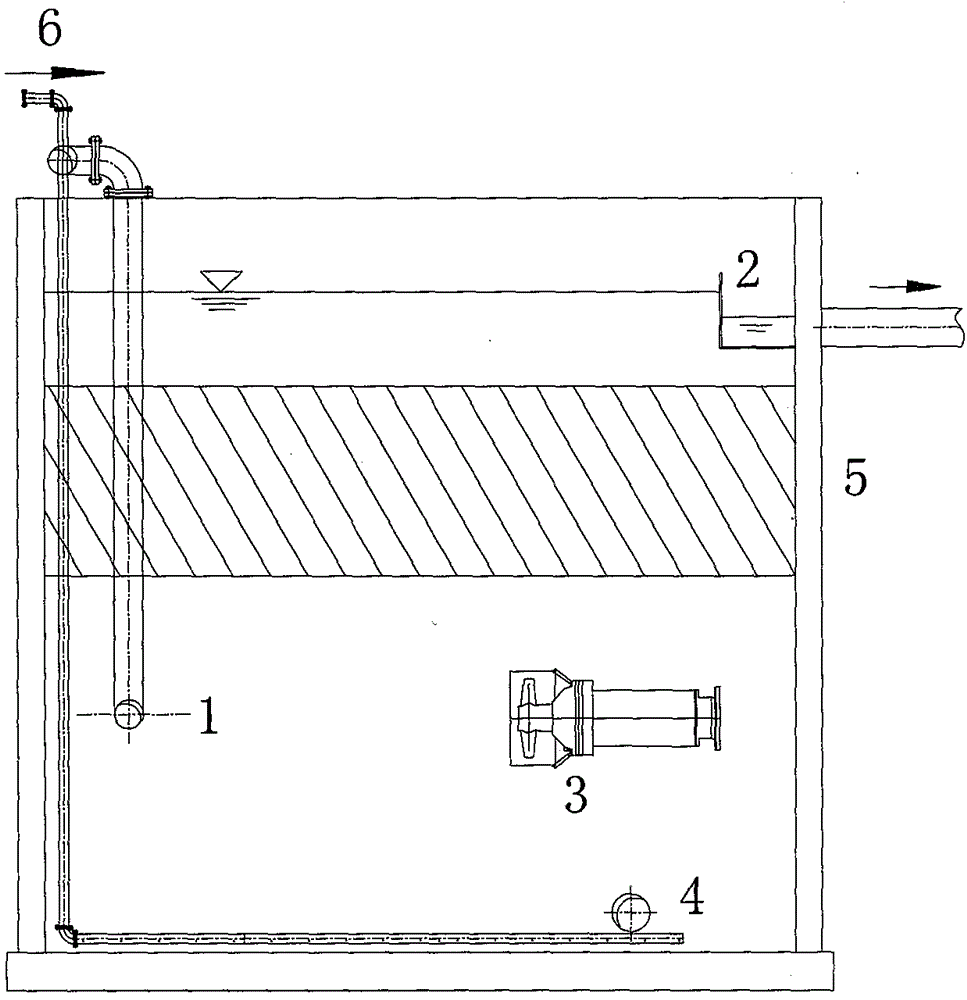

[0017] As shown in the figure, in the SBR reaction tank, the raw sewage enters the reaction tank from the water inlet distributor 1 of the SBR reaction tank through the water inlet perforated pipe or the water inlet flower wall. 2 Drain the reaction pool. The water intake is generally 1 / 4-3 / 4 of the effective volume of the SBR reaction tank. When the water intake reaches the set value according to the water volume or time, the water intake pump is turned off.

[0018] 2. Mud discharge process

[0019] After the water inflow and drainage process is completed, the sludge pump is turned on to discharge the settled residual sludge out of the SBR reaction tank through the sludge discharge pipe 4, and after a certain amount of residual sludge is discharged, the sludge discharge pump is turned off. The water level in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com