Oil tank reinforcement core solder filling machine

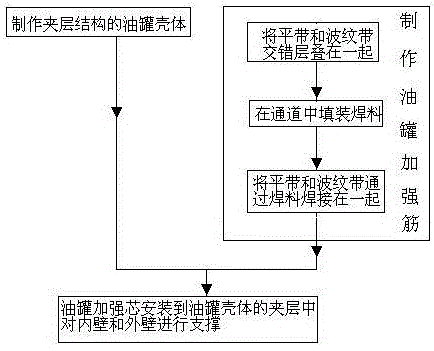

A technology for strengthening cores and oil tanks, applied in the field of oil tank processing, can solve the problems of excessive solder and difficult control of filling volume, and achieve the effects of improved utilization, light weight, and thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment one, see Figure 5 , The oil tank reinforced core solder filling machine used in the present invention includes a frame 1, a solder filling mechanism 2, a material feeding tank 4, a solder flow controller 5 and a solder cleaning and recovery mechanism 6 arranged on the frame.

[0053] The frame 1 is provided with lifting feet 11 . This facilitates high-level docking with adjacent equipment during assembly-line operations.

[0054] The solder filling mechanism 2 includes a first oil tank reinforcing core support hole 21 , a solder injection cylinder 22 , a first cylinder 23 , a pressing plate 24 , a second cylinder 25 and two first lifting guide rods 26 . The support hole 21 of the first oil tank reinforcing core is fixed on the frame 1 . The solder injection cylinder 22 is located below the support hole 21 of the first oil tank reinforcement core and its upper end is connected with the support hole 21 of the first oil tank reinforcement core. The first cyl...

Embodiment 2

[0069] Embodiment two, the difference with embodiment one is:

[0070] see Figure 9, The oil tank reinforcement core solder filling machine is also provided with an oil tank reinforcement core transfer mechanism 9 . The oil tank reinforcing core transfer mechanism 9 includes a swing arm 91 , a suction cup 92 and a driving device 93 . One end of the swing arm 91 is connected with the suction cup 92 , and the other end is connected with the driving device 93 . The driving device 93 is a motor. The centerline of the first oil tank reinforcement core support hole 21 is parallel to the centerline of the second oil tank reinforcement core support hole swing arm 91 . The centerline of the swing axis of the swing arm 91 is perpendicular to the plane defined by the centerline of the support hole of the first oil tank reinforcement core and the centerline of the swing arm of the second oil tank reinforcement core support hole. The distance between the centerline of the swing axis o...

Embodiment 3

[0085] Embodiment three, see Figure 16 , the difference with the second embodiment is: the corrosive liquid storage tank 34 is provided with a wave-dissipating plate 341 floating on the corrosive liquid 37 in the corrosive liquid storage tank. The shell 351 passes through the wave breaking plate 341 in a liftable manner along the up and down direction. The peripheral surface of the wave breaking plate 341 abuts against the side wall of the corrosive liquid storage tank 34 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com