Stewed food cooling device and stewed food cooling method

A cooling device and food technology, which is applied in the field of stewed food, can solve the problems of being unusable, and achieve the effects of easy cleaning, avoiding direct contact, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

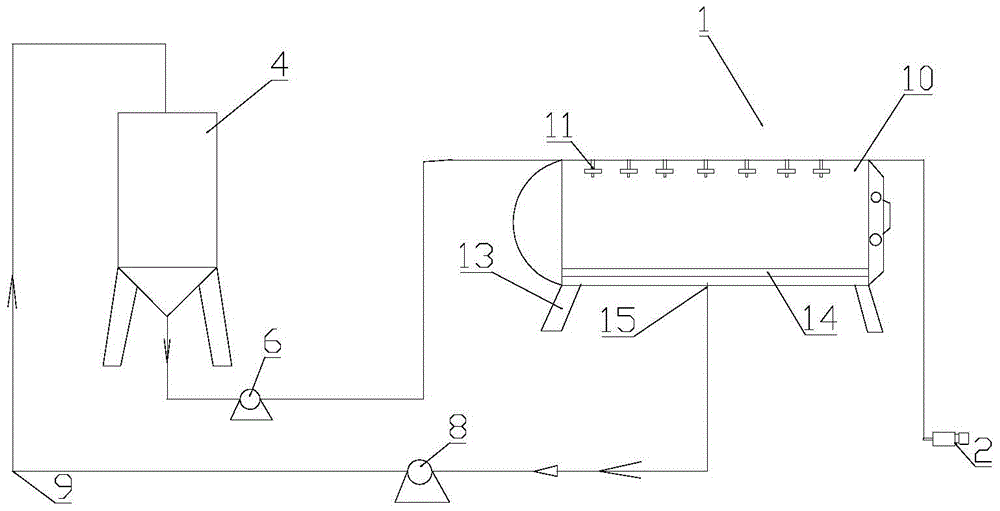

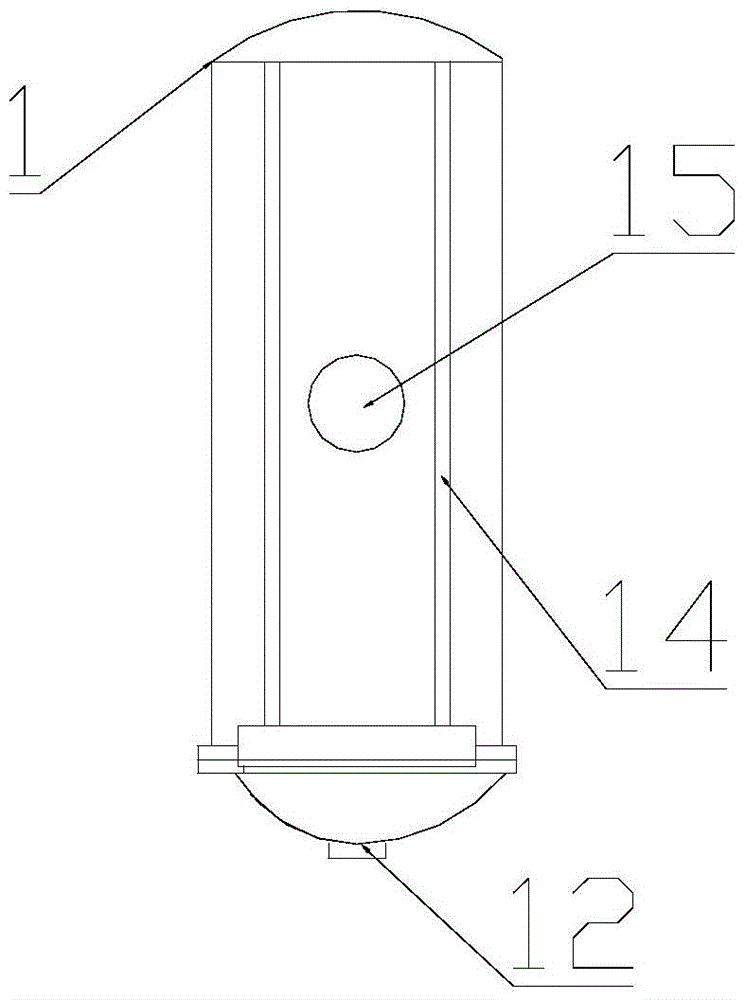

Method used

Image

Examples

Embodiment 1

[0048] Step 1 According to the marinade table of the marinating process, prepare a cooling marinade with the same concentration of ingredients as in the marinating process.

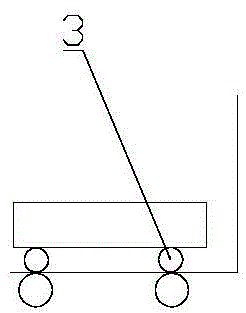

[0049] Step 2 Put the marinated dried tofu into the material basket while it is still hot, quickly push it into the vacuum quick-cooling tank, and close the airtight door of the vacuum quick-cooling tank.

[0050] Step 3: Turn on the vacuum pump to reduce the pressure of the vacuum quick-cooling tank to 1kPa, the boiling point of water to 20°C, the moisture on the surface of the dried bean curd to evaporate rapidly, and the temperature of the dried bean curd to drop rapidly.

[0051] Step 4: Turn on the marinade delivery pump, and after cooling the marinade through the plate heat exchanger, the temperature drops to 3°C.

[0052] Step 5: Turn on the switch of the marinade nozzle, and spray the cooled marinade at 3°C into the vacuum quick-cooling tank to condense the water vapor.

[0053] Step 6 When the...

Embodiment 2

[0057] The difference from Example 1 is: the pressure of the vacuum quick-cooling tank is 1 kPa; the temperature of the cooling marinade is 0°C; the cooling marinade is in a flowing state for 5 minutes; it is used for processing pig trotters.

Embodiment 3

[0059] The difference from Example 1 is: the pressure of the vacuum quick-cooling tank is 7kPa; the temperature of the cooling marinade is 10° C.; the cooling marinade is in a flowing state for 15 minutes; it is used for processing beef.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com