Food disc cooling system

A cooling system and disc technology, applied in the fields of food preservation, food science, application, etc., can solve the problems of spray water consumption and surface taste loss, reduce the risk of surface contact microbial contamination, ensure hygienic safety, The effect of improving food hygiene and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

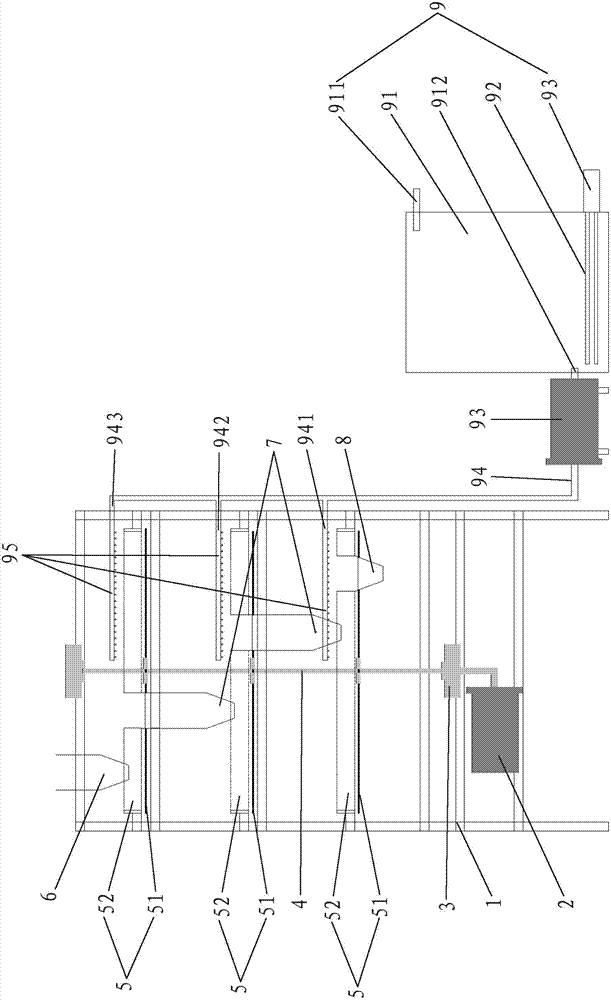

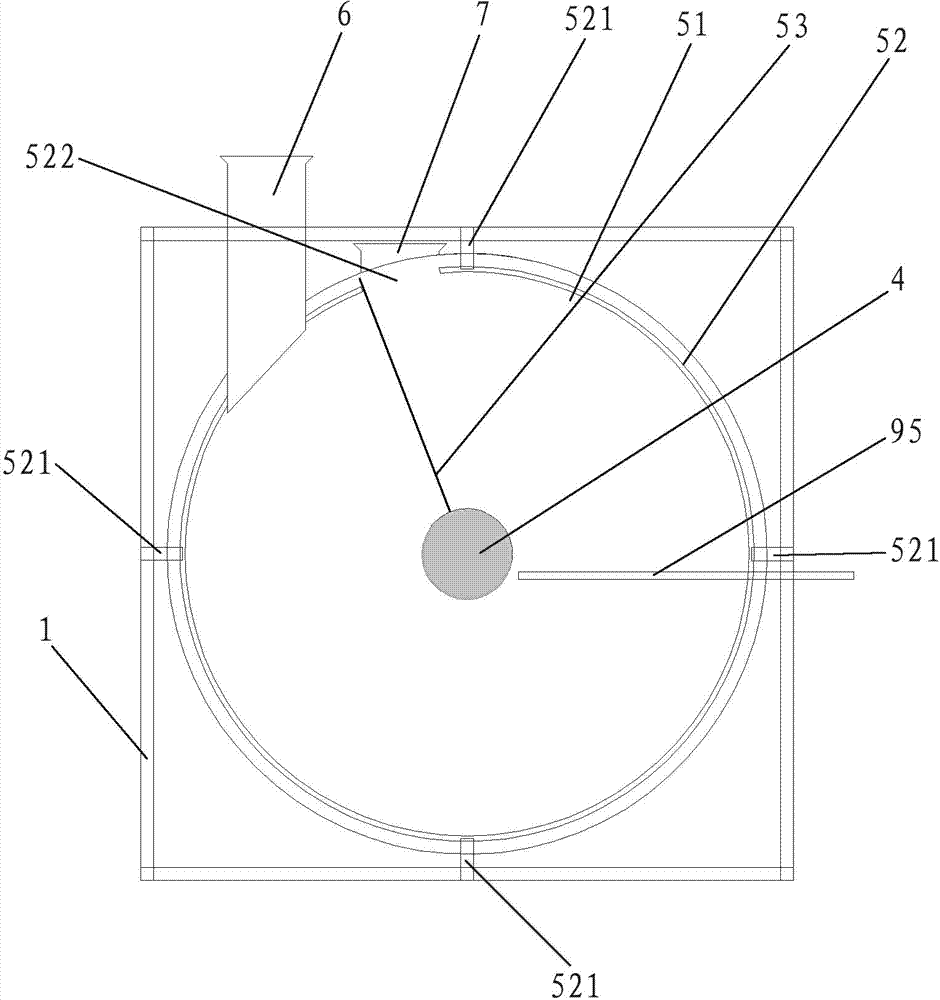

[0030] Such as figure 2 , image 3 Shown is the first embodiment of a food disc cooling system of the present invention, which includes a frame 1, a motor 2, a transmission mechanism 3, a driven shaft 4, three groups of feeding mechanisms 5, a feeding trough 6, two Leading chute 7, discharge chute 8, jet cleaning system 9.

[0031] The motor 2 is fixedly installed on the bottom of the frame 1, the driven shaft 4 is installed vertically at the center of the frame 1 and the two ends of the driven shaft 4 are respectively installed in the center of the top layer of the frame 1 and the center of the second bottom layer in a rotatable manner. At the position, the motor 2 is connected to the bottom of the driven shaft 4 through the transmission mechanism 3 to drive the driven shaft 4 to rotate.

[0032] The feeding mechanism 5 includes a turntable 51 , a turntable enclosure 52 and a baffle 53 . The turntables 51 of the three groups of feeding mechanisms 5 are fixedly installed o...

Embodiment 2

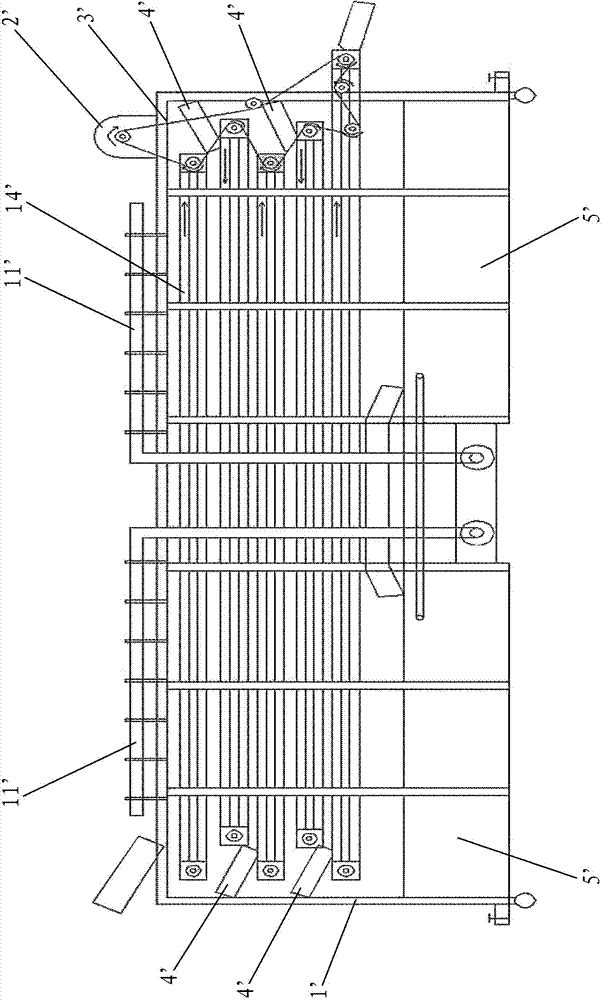

[0043] Figure 4 It is the second embodiment of a food disc cooling system of the present invention. Such as Figure 4 As shown, the motor 2 can also make the driven shaft rotate clockwise through the transmission mechanism 3, and drive the three turntables 5 fixedly mounted on the driven shaft to move clockwise. In terms of mechanical structure, the difference between embodiment 2 and embodiment 1 is that the feed trough on the top turntable in embodiment 2 is in the clockwise direction of the guide chute, and the matured product enters the top turntable and rotates clockwise for one circle. The baffle prevents the material from entering the next layer of turntable through the guide groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com