Electrostatic precipitator

A technology of electrostatic precipitator and cyclone dust collector, applied in the field of electrostatic precipitator device, can solve problems such as large pressure loss and easy blockage of filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Embodiments of the present invention will be described below with reference to the drawings.

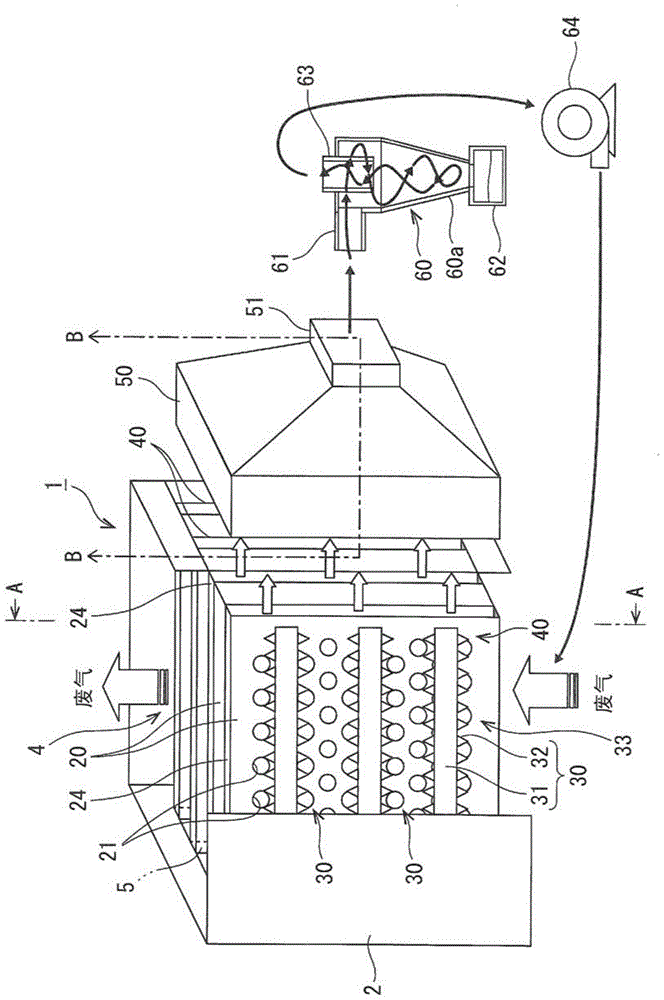

[0063] figure 1 It is a perspective view showing a part of the housing showing the first embodiment of the present invention cut away.

[0064] In the figure, 1 is an electrostatic precipitator, which can capture, for example, particulate matter (PM: Particulate Matter) whose main component is carbon and whose particle size is less than 100 μm, especially the particle size Suspended particulate matter (SPM: Suspended Particulate Matter) below 10 μm.

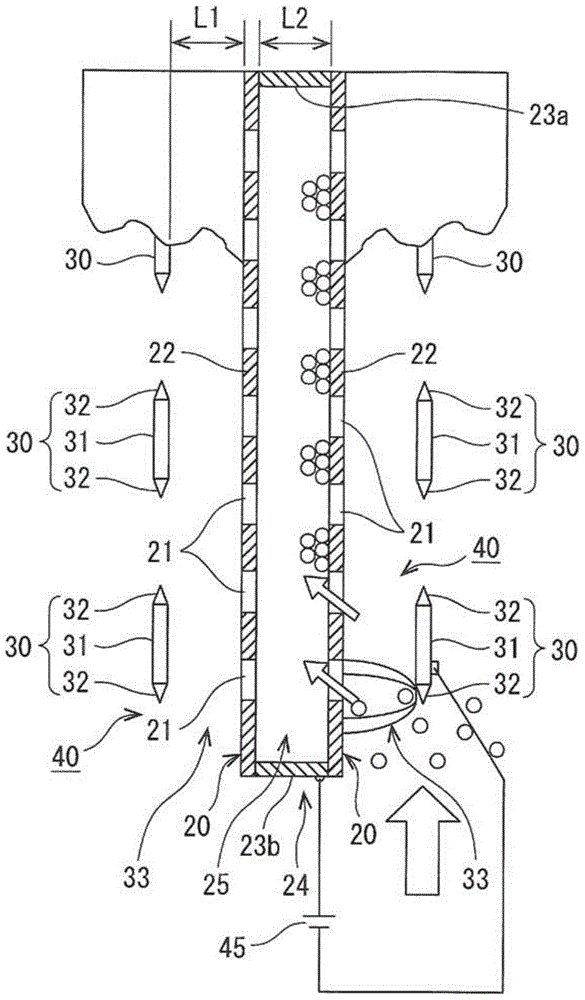

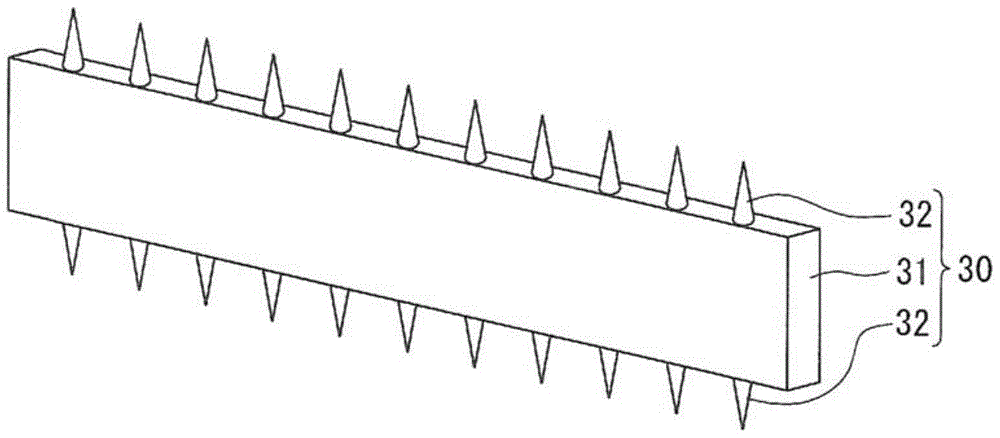

[0065] The electrostatic precipitator 1 has, for example, a cube-shaped frame body 2, and a plurality of groups of dust-collecting electrodes 40 are arranged in the frame body 2, and the dust-collecting electrodes 40 are composed of, for example, square plate electrodes 20 and discharge electrodes 30. Among them, such as figure 2 As shown, the discharge electrode 30 is opposed to one surface of the plate-shaped electrode 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com