Cutting equipment for producing wooden calibrated scale

A technology for cutting equipment and scales, which is applied in the field of cutting equipment for the production of wooden scales, and can solve the problems that operators are easily injured, wood chips are easy to fly everywhere, and wood chips are not easy to fly everywhere.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

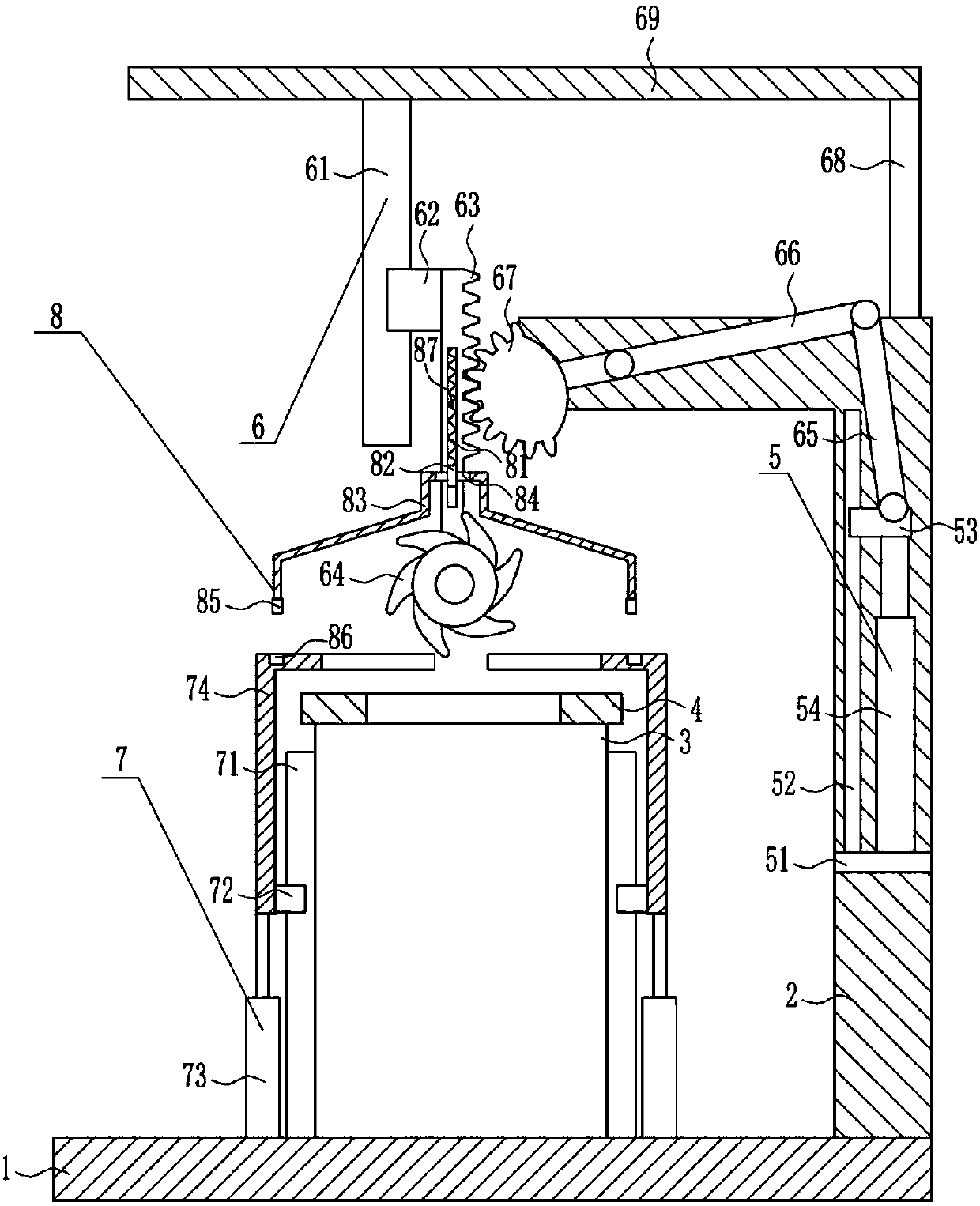

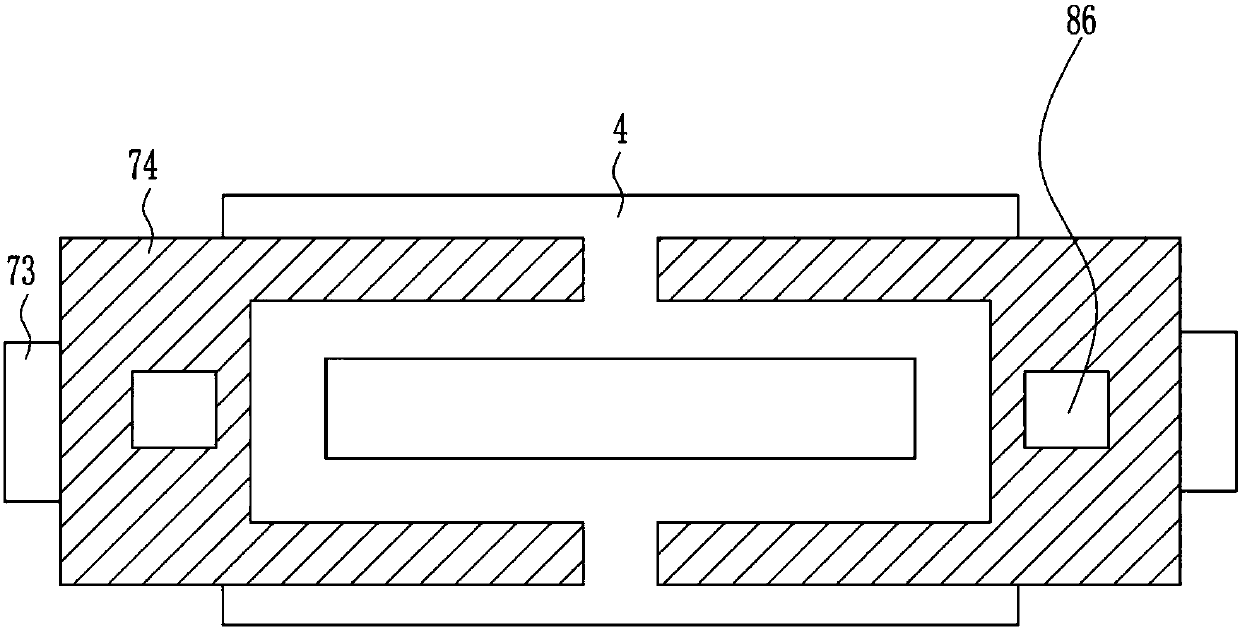

[0035] A cutting device for the production of wooden scales, such as Figure 1-5 As shown, it includes a base plate 1, a 7-type plate 2, an installation block 3, a cutting table 4, an up and down moving device 5 and a cutting device 6. A 7-type plate 2 is installed in the middle of the top right of the base plate 1, and a 7-type plate 2 is installed on the front side. There is an up and down moving device 5, an installation block 3 is installed in the middle of the top of the bottom plate 1, a cutting table 4 is installed on the top of the installation block 3, a cutting groove is opened in the middle of the top of the cutting table 4, and a cutting device 6 is installed on the 7-type plate 2, and the cutting device 6 Cooperating with the up and down moving device 5, the cutting part of the cutting device 6 is located directly above the cutting groove.

Embodiment 2

[0037] A cutting device for the production of wooden scales, such as Figure 1-5 As shown, it includes a base plate 1, a 7-type plate 2, an installation block 3, a cutting table 4, an up and down moving device 5 and a cutting device 6. A 7-type plate 2 is installed in the middle of the top right of the base plate 1, and a 7-type plate 2 is installed on the front side. There is an up and down moving device 5, an installation block 3 is installed in the middle of the top of the bottom plate 1, a cutting table 4 is installed on the top of the installation block 3, a cutting groove is opened in the middle of the top of the cutting table 4, and a cutting device 6 is installed on the 7-type plate 2, and the cutting device 6 Cooperating with the up and down moving device 5, the cutting part of the cutting device 6 is located directly above the cutting groove.

[0038] Up and down moving device 5 comprises mounting plate 51, the first slide rail 52, the first slide block 53 and the fi...

Embodiment 3

[0040] A cutting device for the production of wooden scales, such as Figure 1-5 As shown, it includes a base plate 1, a 7-type plate 2, an installation block 3, a cutting table 4, an up and down moving device 5 and a cutting device 6. A 7-type plate 2 is installed in the middle of the top right of the base plate 1, and a 7-type plate 2 is installed on the front side. There is an up and down moving device 5, an installation block 3 is installed in the middle of the top of the bottom plate 1, a cutting table 4 is installed on the top of the installation block 3, a cutting groove is opened in the middle of the top of the cutting table 4, and a cutting device 6 is installed on the 7-type plate 2, and the cutting device 6 Cooperating with the up and down moving device 5, the cutting part of the cutting device 6 is located directly above the cutting groove.

[0041] Up and down moving device 5 comprises mounting plate 51, the first slide rail 52, the first slide block 53 and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com