A mechanically connected conduction-cooled semiconductor laser stack package structure

A technology of conduction cooling and mechanical connection, which is applied in the direction of semiconductor laser devices, semiconductor lasers, laser devices, etc., and can solve the problem that the bar affects the output power and output beam of the laser, the laser chip of the electrode connection block cannot be replaced, and the semiconductor laser device can no longer be used. and other problems to achieve the effect of avoiding welding voids, avoiding complex shape and structure, and reducing the risk of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following embodiment is the best embodiment of the present invention, but those skilled in the art should know that this embodiment does not limit the present invention after reading the foregoing solutions.

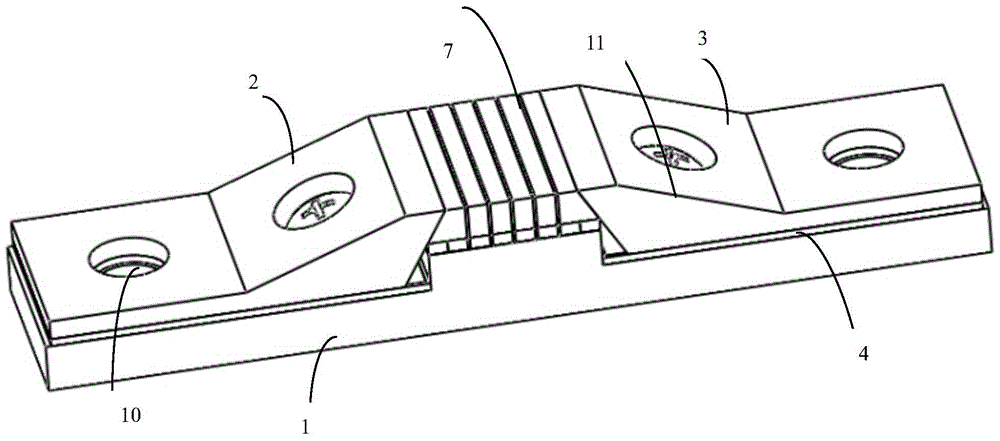

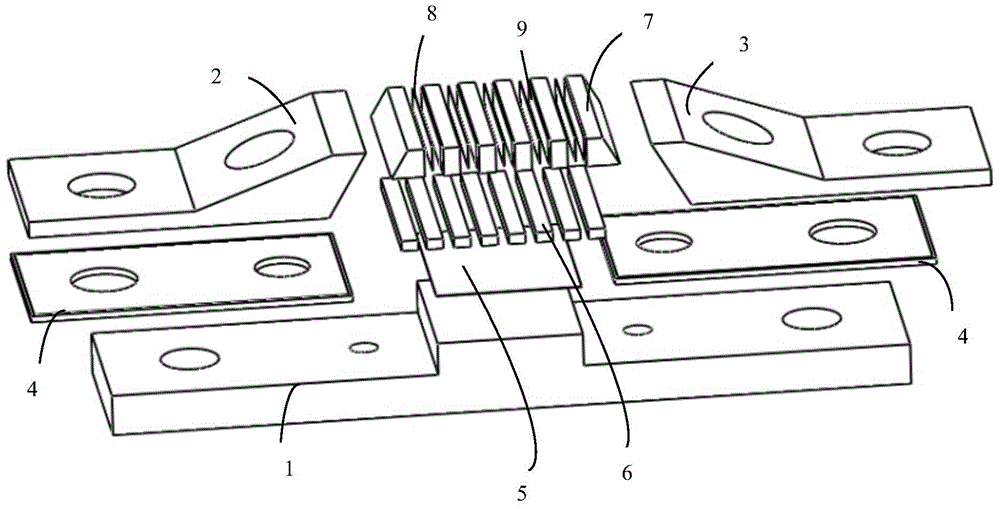

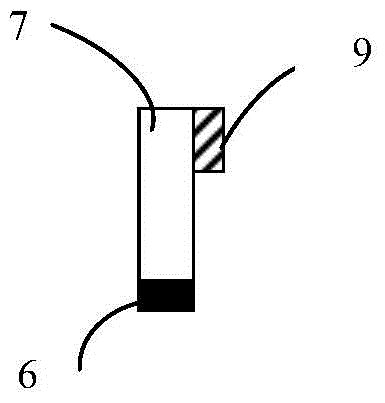

[0034] The conduction cooling type semiconductor laser array of the present embodiment, such as figure 1 and figure 2 The shown includes a basic heat sink 1, a positive electrode connection block 2, a negative electrode connection block 3 (the crimping part is wedge-shaped) and a laser stack mainly composed of a plurality of chip modules. The positive electrode connection block 2 and the negative electrode connection block 3 are installed on the basic heat sink through the insulating sheet 4, and the laser array is installed on the basic heat sink through the insulating structure, and the core insulating structure 5 also has heat conduction and stress release properties; the chip module mainly It includes a substrate 7 and a laser chip 9 welded to the substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com