High-capacity and low-loss full-dry type optical cable

A low-loss, all-dry technology, applied in light guides, optics, clad optical fibers, etc., can solve the problems of high price and immature technology, and achieve the effects of improving work efficiency, reducing high-power amplification, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

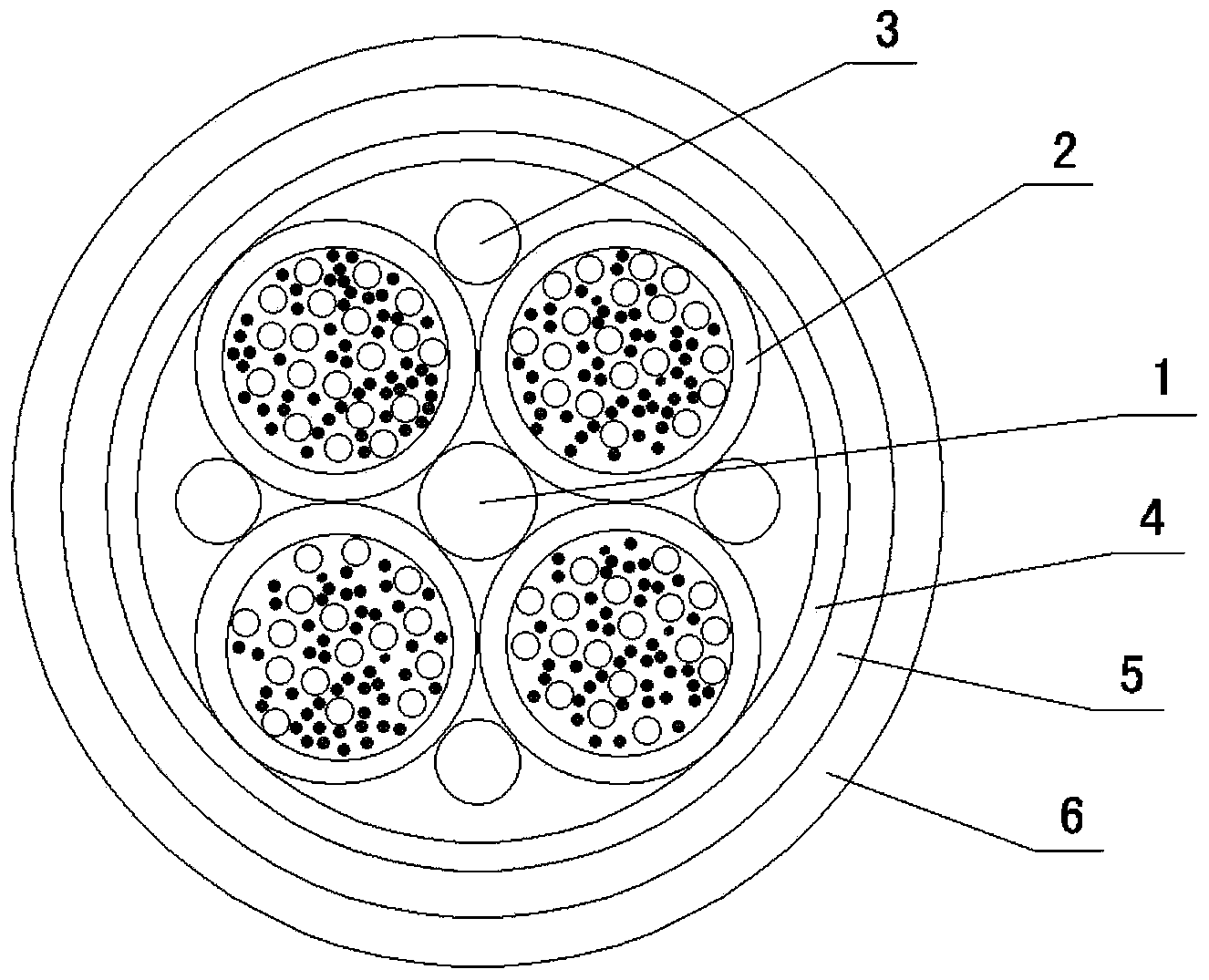

[0035] see figure 1 , the structural form of the large-capacity low-loss all-dry optical cable in this embodiment is: a central strengthening member 1 is arranged in the center, and each optical fiber unit 2 is arranged around the central strengthening member 1 and filled with a water-blocking rope 3 to form a cable core. On the periphery of the cable core, an inner sheath 4, a metal armor layer 5 and an outer sheath layer 6 are sequentially arranged from the inside to the outside;

[0036] The central reinforcement 1 is an aramid fiber rope or a carbon fiber rope;

[0037] The inner sheath 4 is formed by extruding polyethylene plastic;

[0038] The metal armor layer 5 is formed by loose winding of galvanized thin steel wires;

[0039] The outer sheath layer 6 is extruded from wear-resistant linear low-density polyethylene LLPE, with a thickness of 0.5-1.8mm;

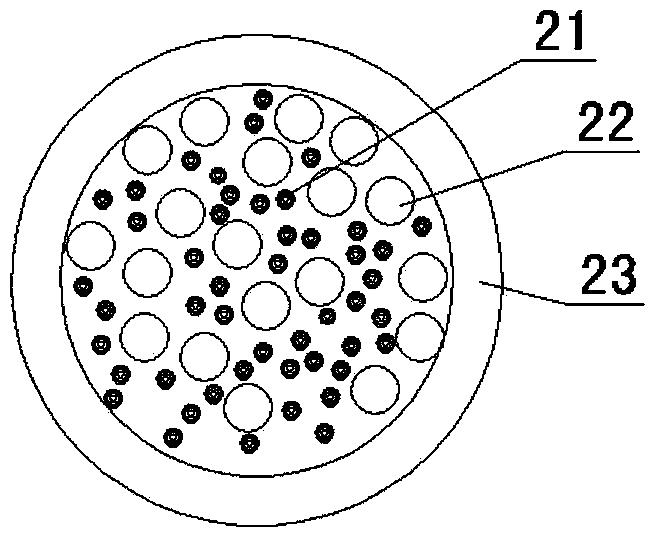

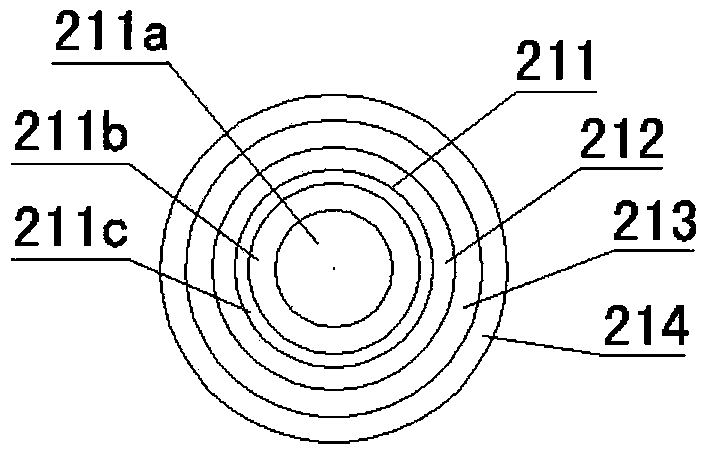

[0040] Such as figure 2 and image 3 As shown, in the present embodiment, the optical fiber unit 2 bundles a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com