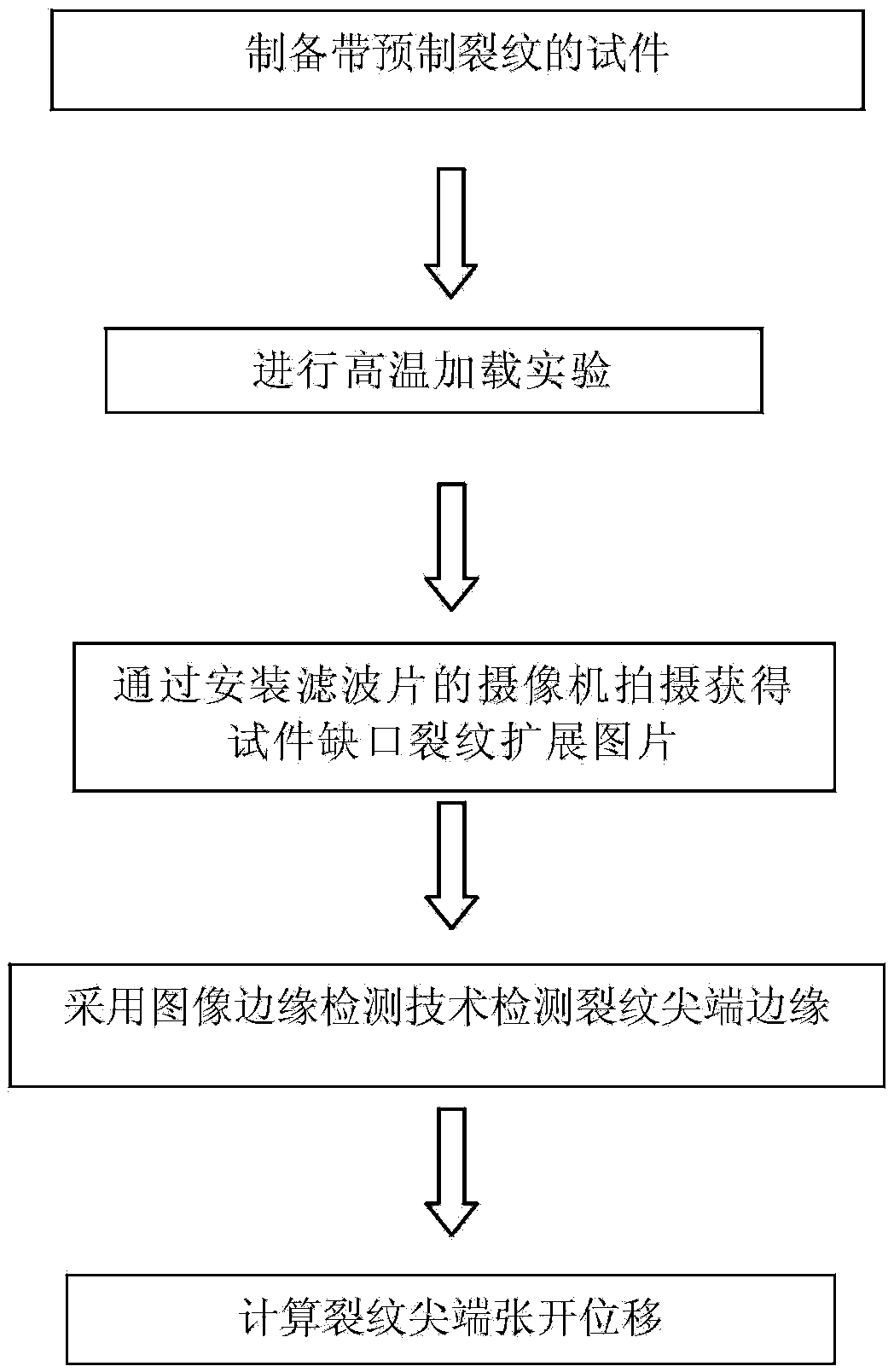

CTOD (crack-tip opening displacement) measurement method based on high-temperature image processing

A crack tip, opening displacement technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of complicated installation and use of high-temperature extensometers, inability to measure crack tip opening displacement, and inability to further reveal the real-time specific process of the specimen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] This method carried out experiments at 600°C, 800°C, 1000°C, 1200°C, 1400°C and 1600°C respectively, among which the high temperature experiment results at 1200°C were selected for specific explanation:

[0043] a. The superalloy Nb521 is made into a unilateral notched beam specimen (the specific size details meet the requirements of GB / T 2358-94);

[0044] b. Carry out high-temperature three-point bending experiment on the prepared Nb521 specimen, and the experimental temperature is a constant temperature of 1200 °C;

[0045] c. In this example, there is an observation hole with a diameter of 12mm on the heating furnace wall of the high-temperature three-point bending experiment, and the whole experiment process is photographed by a high-speed camera equipped with a high-temperature filter system, and the picture of the notch crack expansion of the test piece is obtained;

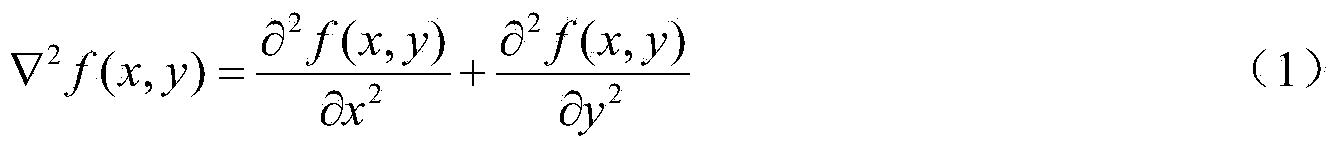

[0046] d. Use the image edge detection technology to get the edge of the crack tip, and calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com