Flexible capacitive pressure sensing device

A technology of sensing device and flexible capacitor, which is applied in the direction of fluid pressure measurement, measuring device, and measuring force using capacitance change, can solve the problems of poor insulation of capacitive sensors, poor recovery under pressure, and easy crosstalk of capacitive sensors, and achieve electrical conductivity. Excellent performance and flexibility, good elasticity, and the effect of improving service life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

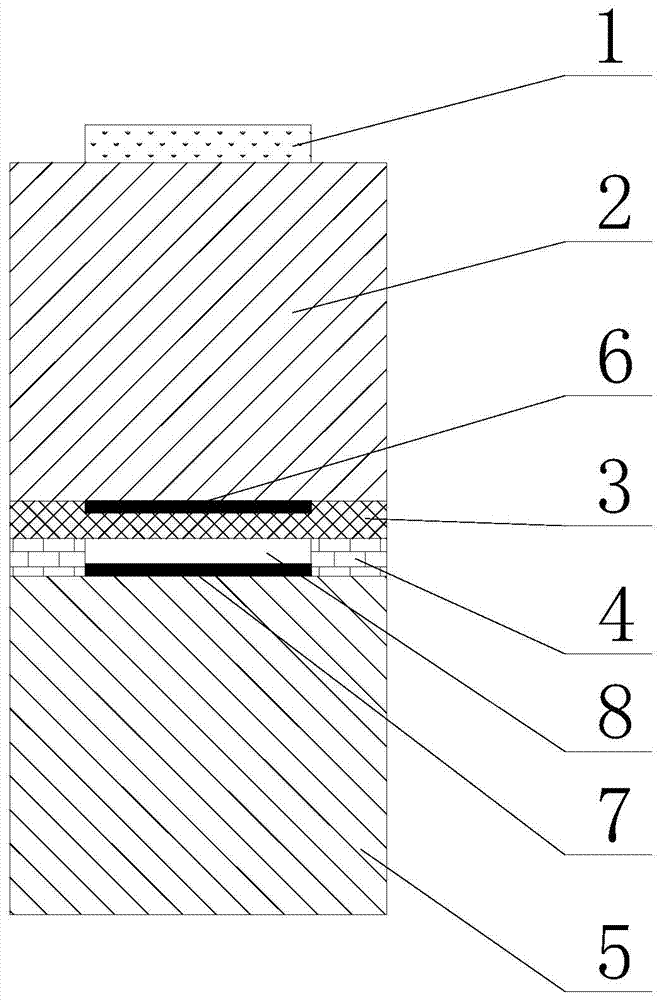

[0044] Such as figure 1 As shown, the main materials used in the five parts of the pressure action area 1, the upper plate 2, the insulating protection layer 3, the gasket 4 and the lower plate 5 are all flexible PDMS membranes, and the sizes of each part are different. The HR-323TPDMS special silicone adhesive glued into a whole. The PDMS film is made by a spin-coating method, has a uniform thickness, and has a high dielectric constant, which can reduce crosstalk between capacitors, and is soft, elastic, and easy to deform, and can increase the sensing sensitivity of the capacitor.

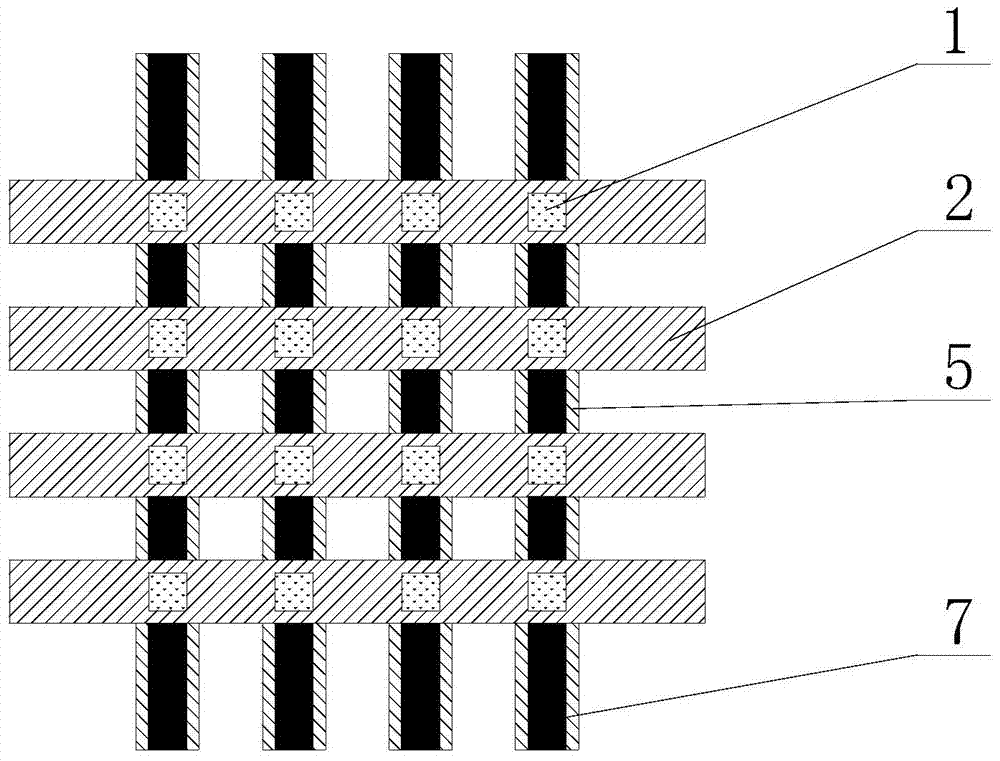

[0045] Such as figure 2 As shown, the upper pole plate 2 and the lower pole plate 5 extend on two different horizontal levels in the transverse direction and the longitudinal direction respectively, and the intersection area between the upper pole plate 2 and the lower pole plate 5 is where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com