Camshaft signal panel angle detection gauge

A technology of angle detection and signal disc, which is applied in the direction of measuring devices and instruments, can solve the problems that the camshaft press-fitting accuracy cannot be guaranteed, cannot be inspected one by one, and can only be inspected randomly, and achieves simple structure, easy operation, and easy calibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

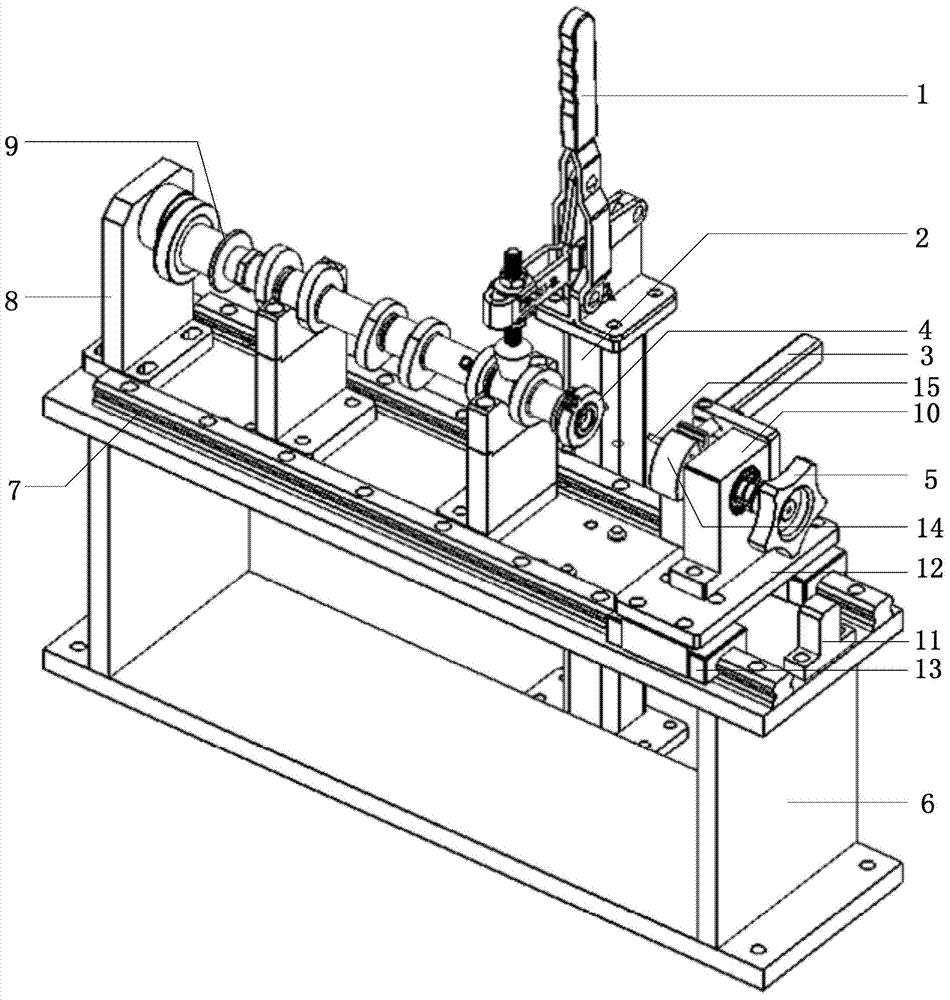

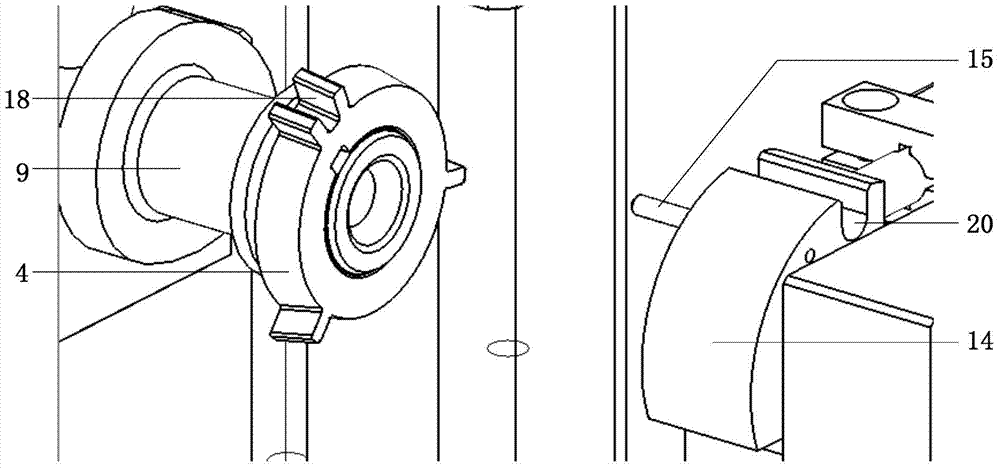

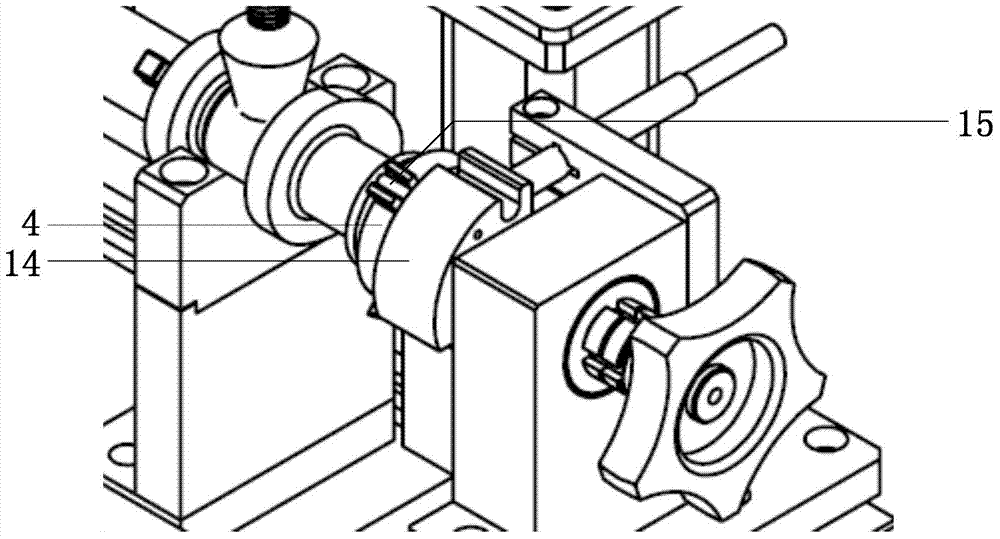

[0018] In order to ensure the angle between the signal disc 4 and the angle positioning pin 17 after being pressed into the camshaft 9, the camshaft signal disc angle detection tool of the present invention is used to detect the angle of the pressed signal disc.

[0019] Such as figure 1 As shown, the camshaft signal disc angle detection tool of the present invention mainly includes a support seat 6, a pressing mechanism, an angle positioning mechanism and a detection mechanism. Both the angle positioning mechanism and the detection mechanism are installed on the support base 6, and the detection mechanism is located at one end of the angle positioning mechanism. The clamping mechanism adopts a clamp 1, which is located on one side of the angle positioning mechanism. The clamp 1 is fixed on the clamp bracket 2, and the clamp bracket 2 is installed on the support seat 6.

[0020] The angle positioning mechanism comprises a top seat 8, a rear support and a front support which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com