Low-noise integrated centrifugal fan

A centrifugal fan, low-noise technology, applied in liquid fuel engines, mechanical equipment, machines/engines, etc., can solve the problems of high vibration noise, unstable shafting, and excessive vibration of centrifugal fans, and achieve high power density, structural Compact, low-frequency vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

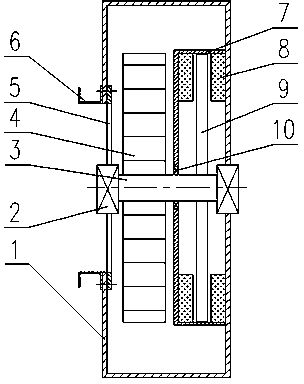

[0026] Example 1: as figure 1 As shown, a low-noise integrated centrifugal fan includes a volute 1, a support bearing 2, a main shaft 3, an impeller 4, an inlet deflector 5, an inlet flange 6, a motor housing 7, a flattened motor stator 8, The flattened motor rotor 9 and the flattened motor support bearing 10 .

[0027] The impeller 4 is installed on the main shaft 3, the flattened motor rotor 9 is installed on the main shaft 3, the flattened motor stator 8 is installed on the volute 1 and the flattened motor housing 7, respectively, the inlet deflector 5 and the inlet flange 6 Installed on the volute 1, the main shaft 3 is respectively installed on the volute 1 and the inlet deflector 5 through the support bearing 2, and the impeller 4 is rotated to do work by the rotation of the flattened motor rotor 8, and then the mechanical energy is converted into the pressure energy of the gas to be transported. and kinetic energy.

Embodiment 2

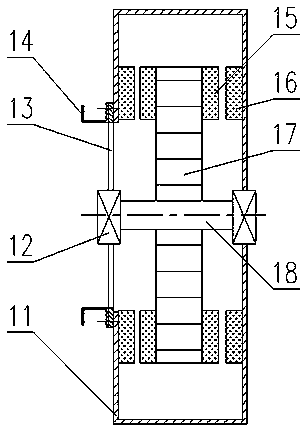

[0028] Embodiment 2: as figure 2 As shown, a low-noise integrated centrifugal fan includes a volute 11 , a support bearing 12 , an inlet deflector 13 , an inlet flange 14 , a flattened motor rotor 15 , a flattened motor stator 16 , an impeller 17 , and a main shaft 18 .

[0029] The impeller 17 is installed on the main shaft 18, the flat motor rotor 15 is installed on the impeller 15, the flat motor stator 16 is installed on the volute 11, the inlet deflector 13 and the inlet flange 14 are installed on the volute 11, and the main shaft 17 The support bearing 12 is respectively installed on the volute 11 and the inlet deflector 13, and the rotor 15 of the flattened motor is rotated to drive the impeller 17 to rotate to do work, and then convert the mechanical energy into the pressure energy and kinetic energy of the conveyed gas.

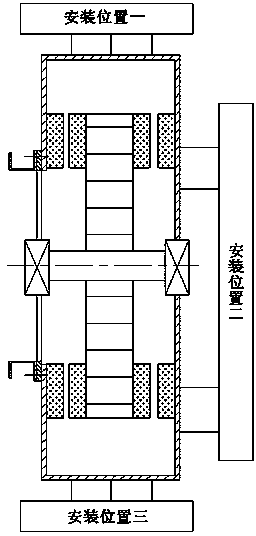

[0030] In the above embodiment, in addition to the design of installing the flattened motor part inside the fan volute, the flattened motor part ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com