Sealed decompression intake tube pad

A technology of air intake pipe and air intake hole, which is applied in the direction of engine sealing, engine sealing device, exhaust device, etc., can solve the problems of weak sealing effect, complicated process, weak anti-vibration ability, etc., and achieve novel structure, Good stability and easy positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

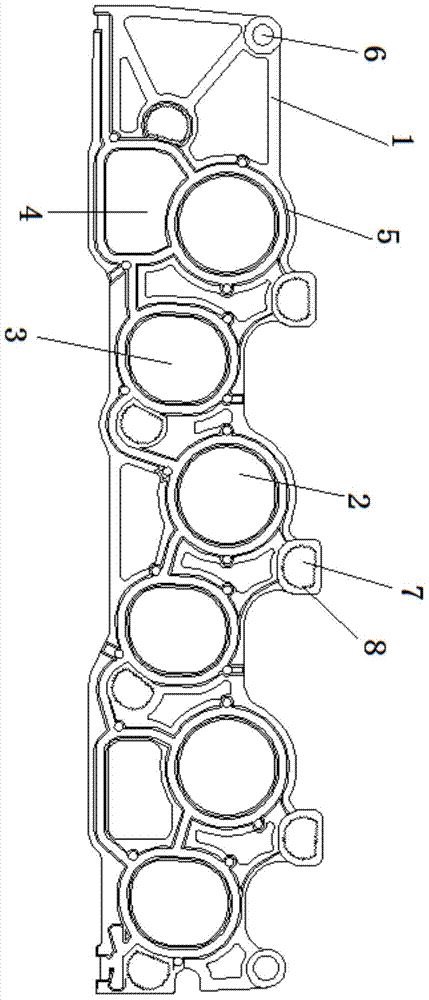

[0009] Such as figure 1 As shown, a sealed and decompressed air intake pipe gasket includes a gasket body 1. Hollow structures are provided in multiple places on the gasket body 1. The gasket body 1 is provided with three circular air inlet holes 2, and each air inlet hole The lower right side of 2 is respectively provided with a water hole 3, and the lower side of the two air intake holes 2 on both sides is respectively provided with a tappet hole 4, and the upper end surface of the gasket body 1 surrounds the air intake hole 2, the water hole 3. The inner wall of the tappet hole 4 is provided with a ring-shaped rubber sealing rib 5, and the two ends of the gasket body 1 are respectively provided with mounting holes 6, and several positioning holes 7 are distributed on the gasket body 1. On the inner wall of the positioning hole 7 There are 8 sawtooth patterns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com