Self-elevating drilling platform cantilever beam sliding device

A technology for drilling platforms and sliding devices, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of increased processing costs, difficult control, limited bearing capacity, etc., to reduce geometric deformation or bending, The effect of high safety and reliability and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

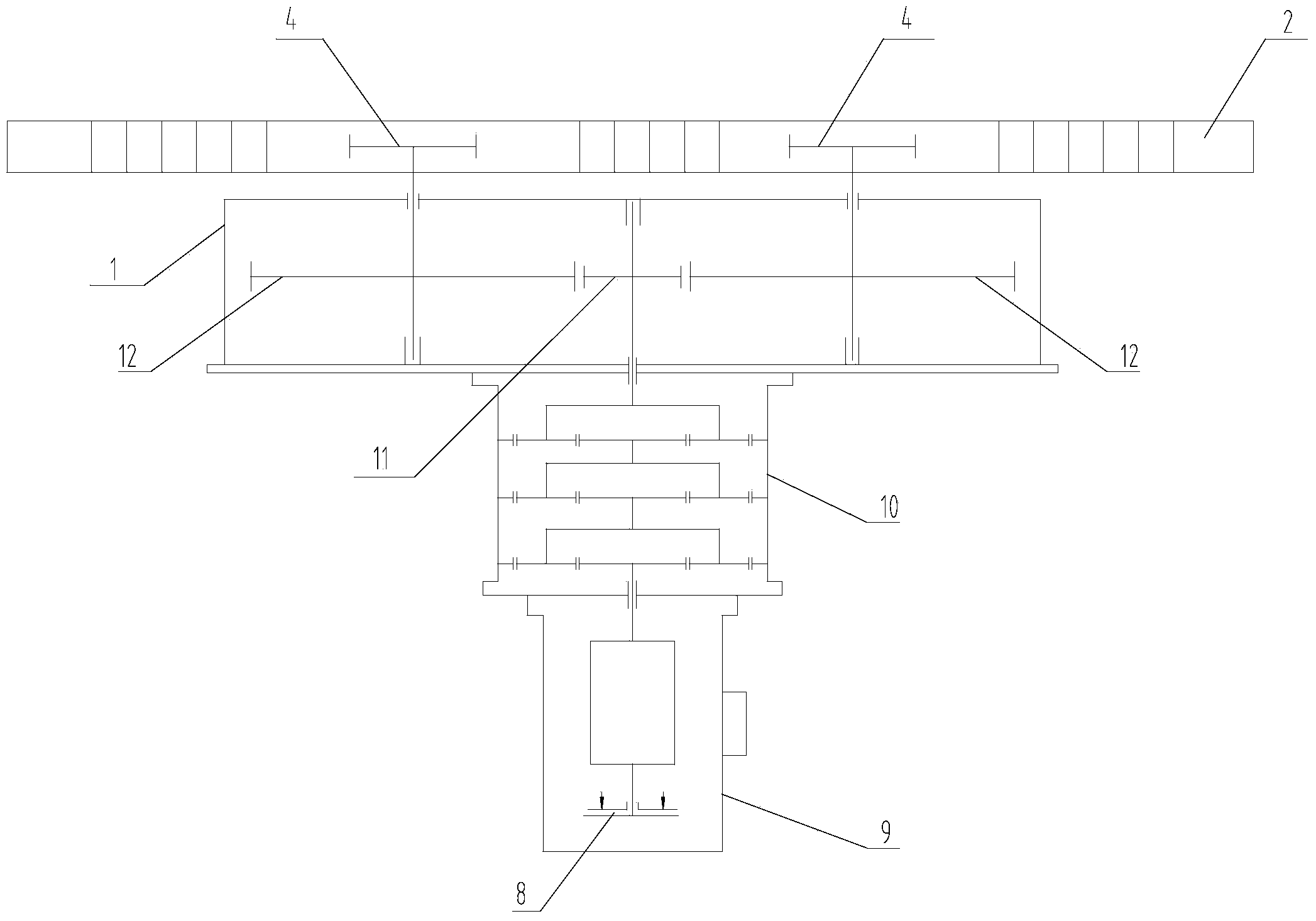

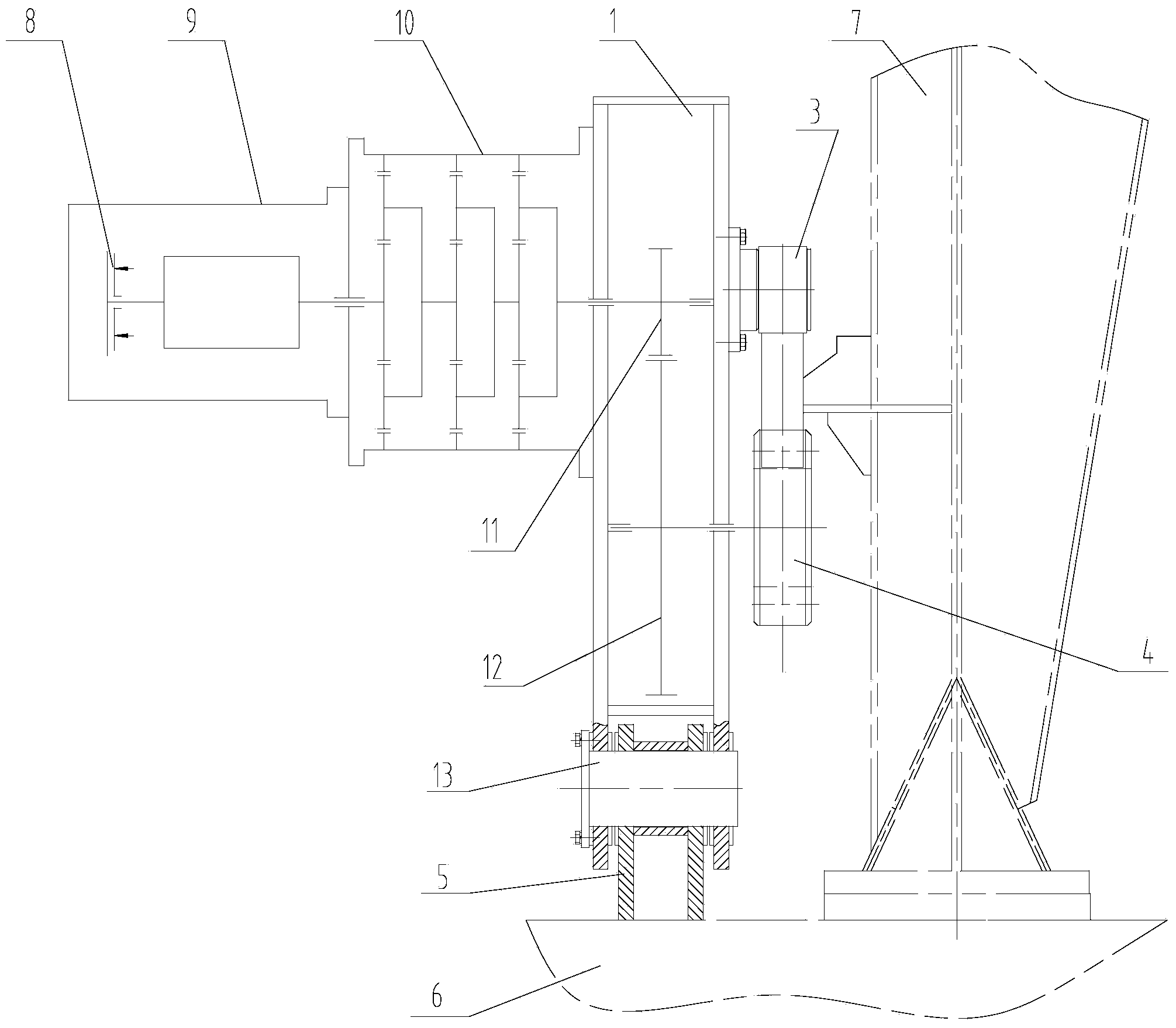

[0038] A self-elevating drilling platform cantilever beam 7 sliding device, which is installed on the main deck 6 of the platform, and is located beside the cantilever beam 7, which includes:

[0039] The multi-stage planetary reducer 10 is installed on the side of the sliding body 1, on the side opposite to the roller assembly 3 and the drive gear 4, and a power source is arranged beside the multi-stage planetary reducer 10 to drive its internal gears to rotate , the direction of rotation can be changed;

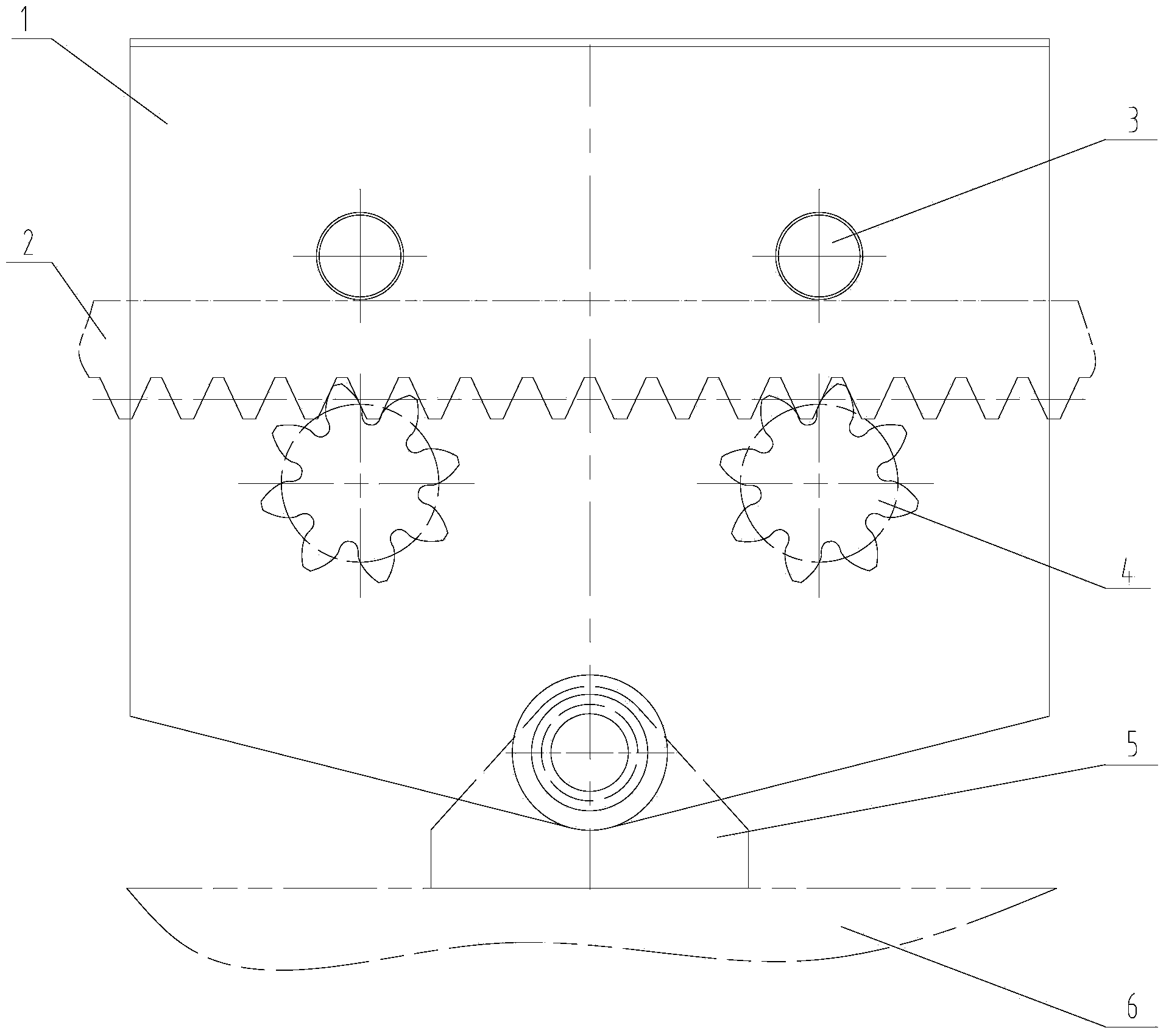

[0040] Sliding body 1, which is installed on the main deck 6 of the platform, a gear pair is arranged inside the sliding body 1, and the gear pair is connected with the output shaft of the multi-stage planetary reducer 10 and driven by it. The outside of the sliding body 1 is equipped with a driving gear 4 driven by the output shaft of the gear pair, and its number is equal to or greater than two. Above or below, a rack 2 is installed between the roller assembly 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com