A kind of production method of anti-snag warp knitting pressed yarn/loop pattern fabric

An anti-snag and loop-forming technology, which is applied in the field of fabric textiles, can solve the problems of destroying the beauty of the fabric, limiting the design space of the pattern, and shortening the service life of the fabric, so as to reduce the possibility of fabric snagging, reduce design limitations, and The effect of increasing the shift range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention are described in detail below, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0029] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

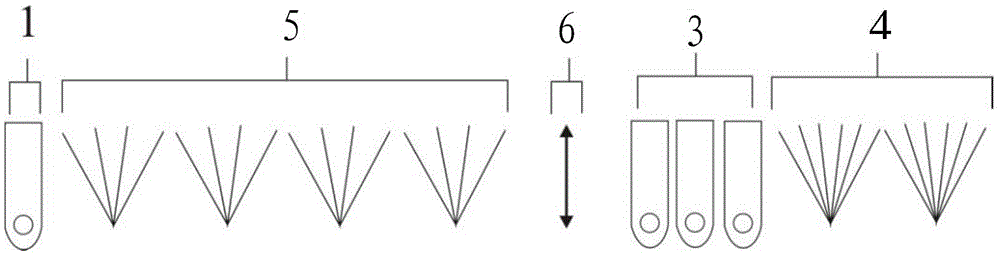

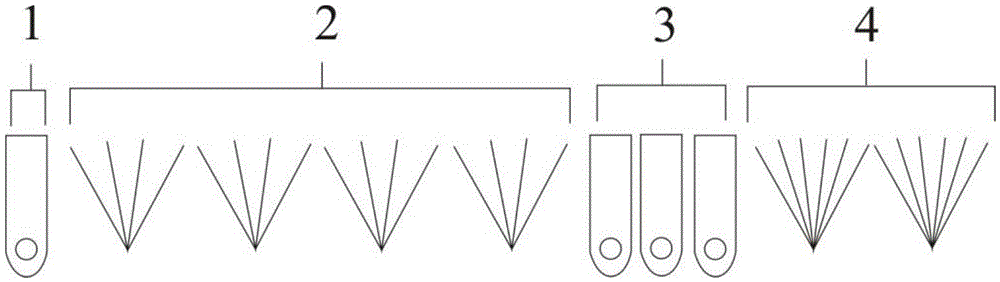

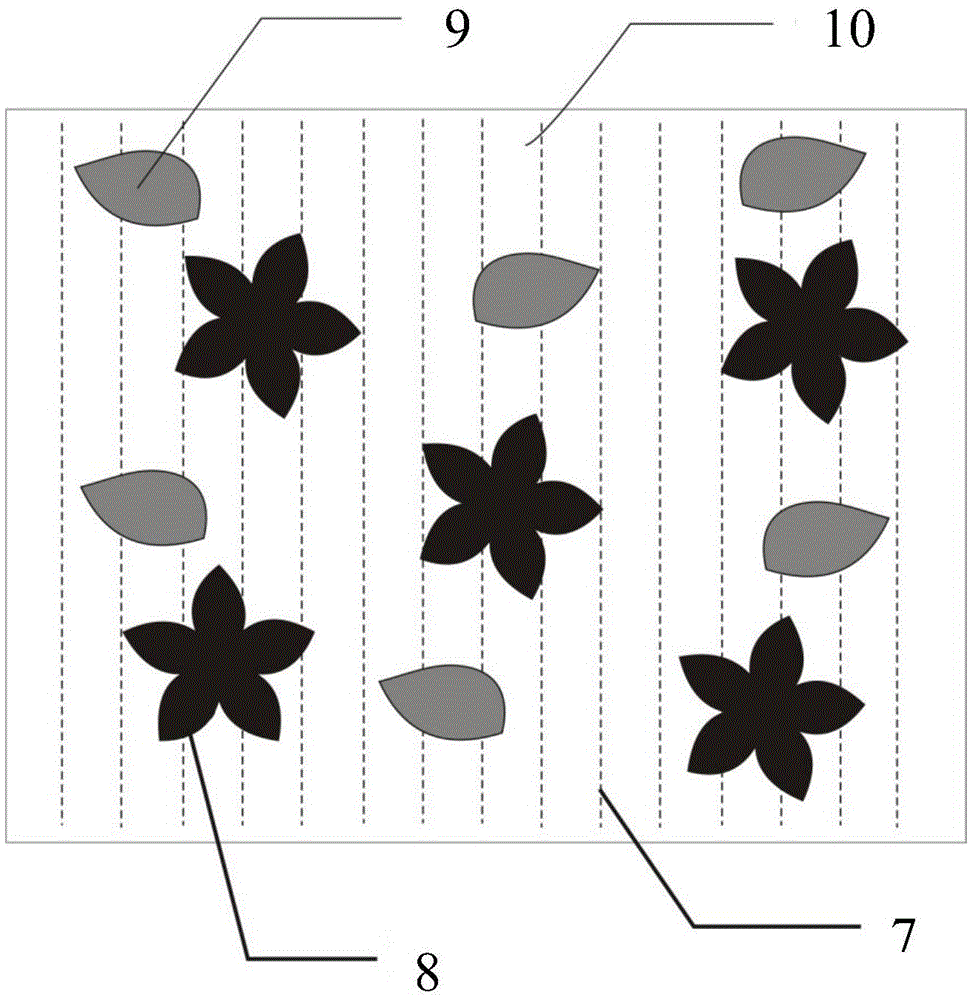

[0030] Such as figure 1 As shown, according to the production method of the anti-snag warp knitted loop pattern fabric according to the specific embodiment of the present invention, the steps are:

[0031] (1) Arrangement of combs: Anti-snag floor comb 1 is arranged at the front, and behind the anti-snag floor comb are sequentially arranged loop-forming pattern combs 2, floor combs 3, and weft-inserting pattern combs 4;

[0032] (2) Yarn preparation: select nylon high elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com