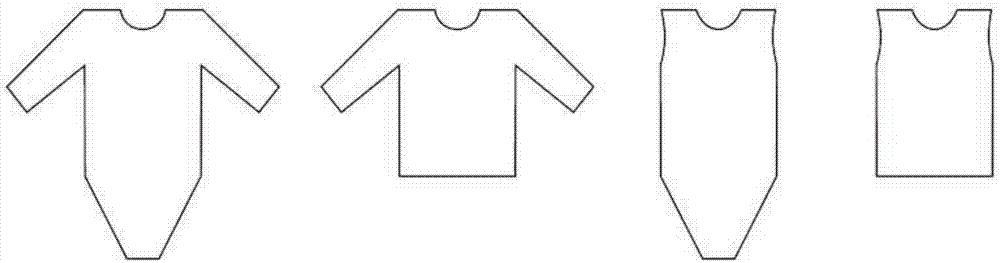

A kind of ultra-thin anti-off underwear produced by cylinder loom and its production process

A technology of a circular loom and production process, applied in protective clothing, application, knitting and other directions, can solve the problems of poor skin tightening and ultra-thin breathability, complex manufacturing methods, and high production costs, and achieve excellent anti-shedding performance, The effect of improving cost performance and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

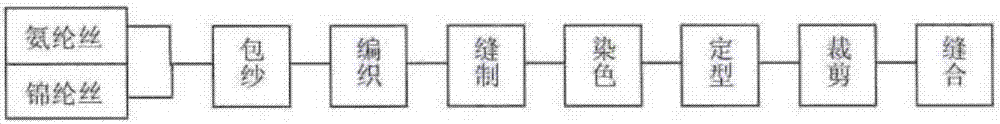

[0033] The production process of the ultra-thin anti-off underwear includes the following steps:

[0034] Step 1, wrapped yarn

[0035] Adjust the temperature of the workshop to 25°C and the relative humidity to 65%. Nylon yarn (other fiber materials can also be selected according to needs) and spandex yarn are used to wrap on a high-speed wrapping machine to make a wrapped yarn suitable for weaving. Among them, the spandex yarn adopts the special spandex of model 20D (other models can also be selected according to the needs), the nylon yarn adopts the model DTY12 / 7 (other models can also be selected according to the needs), the draft ratio is 3.0, and the twist is 1800T / M. Overfeed was 94%.

[0036] Cover yarn under the situation of above-mentioned temperature and humidity, after equilibrating for 5 days, enter weaving step.

[0037] 2. Weaving

[0038] Adjust the temperature of the weaving workshop to 25°C and the relative humidity to 65%. Put the required wrapped yarn in...

Embodiment 2

[0057] 1. Wrapped yarn

[0058] Adjust the temperature of the workshop to 20°C and the relative humidity to 60%. Nylon yarn (other fiber materials can also be selected according to needs) and spandex yarn are used to wrap on a high-speed wrapping machine to make a wrapped yarn suitable for weaving. Among them, the spandex yarn is made of 15D special spandex, the nylon yarn is made of FDY / DTY 8D, the draft ratio is 3.1, the twist is about 1700T / M, and the overfeed is 94.5%. 15D anti-loosening spandex is used as the inner wrapping yarn, and DTY / FDY 8D nylon is used as the outer wrapping yarn to ensure the aesthetics and breathability of underwear when the textile material is made into underwear.

[0059] Cover yarn under the situation of above-mentioned temperature and humidity, after equilibrating for 5 days, enter weaving step.

[0060] 2. Weaving

[0061] Adjust the temperature of the workshop to 20°C and the relative humidity to 60%, send the covered yarn to the cylinder l...

Embodiment 3

[0075] 1. Wrapped yarn

[0076] Adjust the temperature of the workshop to 20°C and the relative humidity to 65%. Nylon yarn (other fiber materials can also be selected according to needs) and spandex yarn are used to wrap on a high-speed wrapping machine to make a wrapped yarn suitable for weaving. Among them, the spandex yarn is made of 20D special spandex, the nylon yarn is made of FDY / DTY 15D, the draft ratio is 2.7, the twist is about 1900T / M, and the overfeed is 93%.

[0077] Cover yarn under the situation of above-mentioned temperature and humidity, after equilibrating for 5 days, enter weaving step.

[0078] 2. Weaving

[0079] Adjust the temperature of the workshop to 20°C and the relative humidity to 60%, send the covered yarn to the computerized cylinder loom (including stockings machine) for weaving, set the horizontal drawing size of the lower machine to 58CM, and make socks into tubes. By adjusting the state of the computer hosiery machine, such as increasing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com