Special cleaning agent for metal part and preparation method thereof

A technology for metal parts and cleaning agent, applied in the field of metal products, can solve the problems of scrapping of processed parts, affecting the precision of instruments, introducing oil stains on the surface, etc., to achieve the effect of easy disposal of waste liquid and no discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

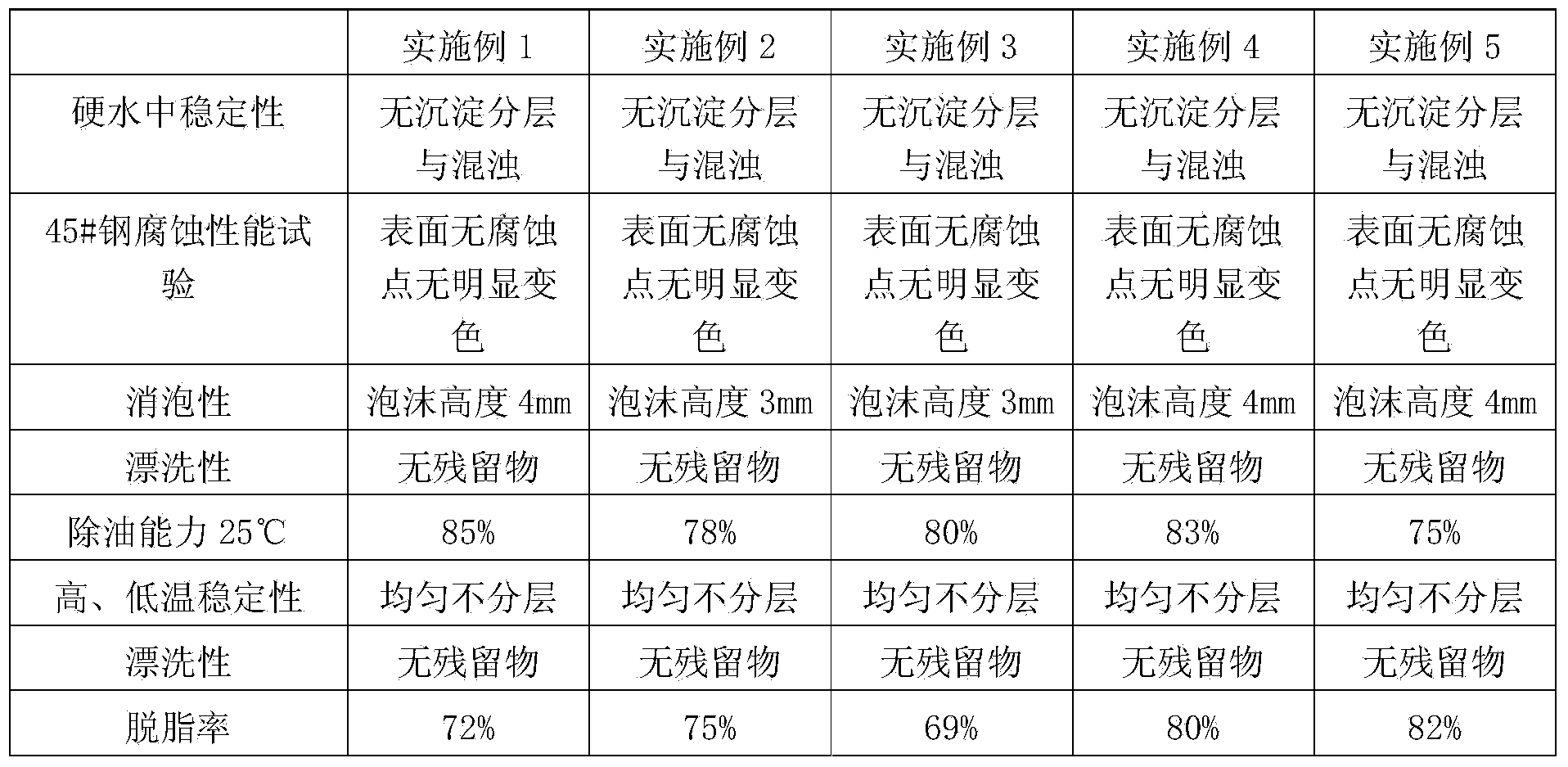

Examples

Embodiment 1

[0018] A special cleaning agent for metal parts, comprising in parts by weight: 3 parts of coconut oil glycol amide, 4 parts of glycerol monocaprate, 3 parts of oleoyl sarcosine octadecylamine, 4 parts of 2-methylpropanesulfonic acid Parts, 5 parts of ethylene glycol alkyl ether, 2 parts of sodium metasilicate, 1 part of sodium glycolate, 2 parts of zinc stearate, 3 parts of diethyl diallyl ammonium chloride, 4 parts of hexamethyltetramine 3 parts, 3 parts of acrylate polymer, 6 parts of deionized water.

[0019] The preparation method of above-mentioned special cleaning agent for metal parts, comprises the following steps:

[0020] Step 1, pour coconut oil glycol amide, glycerol monocaprate, oleoyl sarcosine octadecylamine, 2-methylpropanesulfonic acid, ethylene glycol alkyl ether and water into the stirring tank, and the stirring tank The vacuum degree is -0.08MPa, stir evenly, then heat the stirring tank to 100°C, add sodium metasilicate and sodium glycolate, stir evenly, ...

Embodiment 2

[0024] A special cleaning agent for metal parts, comprising in parts by weight: 4 parts of coconut oil glycol amide, 5 parts of glycerol monocaprate, 4 parts of oleoyl sarcosine stearylamine, 5 parts of 2-methylpropanesulfonic acid Parts, 6 parts of ethylene glycol alkyl ether, 3 parts of sodium metasilicate, 2 parts of sodium glycolate, 4 parts of zinc stearate, 5 parts of diethyl diallyl ammonium chloride, 5 parts of hexamethyltetramine 4 parts, 4 parts of acrylate polymer, 8 parts of deionized water.

[0025] The preparation method of above-mentioned special cleaning agent for metal parts, comprises the following steps:

[0026] Step 1. Pour coconut oil glycol amide, glyceryl monocaprate, oleoyl sarcosine octadecylamine, 2-methylpropanesulfonic acid, ethylene glycol alkyl ether and water into a stirring tank and stir well , the vacuum degree of the stirred tank is -0.09MPa, and then the stirred tank is heated to 110°C, then sodium metasilicate and sodium glycolate are adde...

Embodiment 3

[0030] A special cleaning agent for metal parts, comprising in parts by weight: 5 parts of coconut oil glycol amide, 8 parts of glycerol monocaprate, 6 parts of oleoyl sarcosine stearylamine, 7 parts of 2-methylpropanesulfonic acid Parts, 9 parts of ethylene glycol alkyl ether, 5 parts of sodium metasilicate, 4 parts of sodium glycolate, 6 parts of zinc stearate, 7 parts of diethyl diallyl ammonium chloride, 8 parts of hexamethyltetramine 6 parts, 6 parts of acrylate polymer, 15 parts of deionized water.

[0031] The preparation method of above-mentioned special cleaning agent for metal parts, comprises the following steps:

[0032] Step 1. Pour coconut oil glycol amide, glyceryl monocaprate, oleoyl sarcosine octadecylamine, 2-methylpropanesulfonic acid, ethylene glycol alkyl ether and water into a stirring tank and stir well , the vacuum degree of the stirred tank is -0.1MPa, and then the stirred tank is heated to 100°C, then sodium metasilicate and sodium glycolate are adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com