Preparing method of TiB2 particle reinforced foamed aluminium/aluminium alloy

A technology of particle reinforcement and aluminum alloy, which is applied in the field of porous materials, can solve the problem of low strength of foamed aluminum, and achieve the effects of simple preparation process, controllable pore structure and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

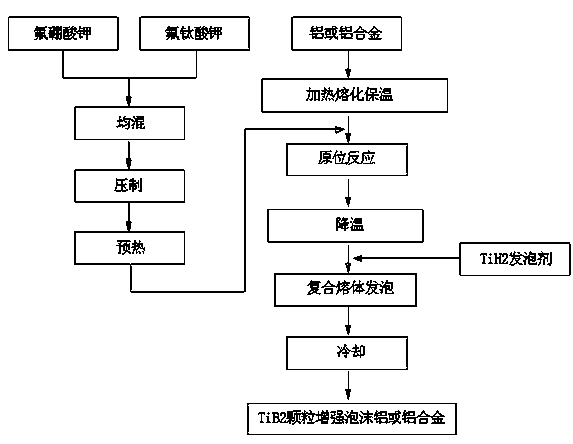

[0029] Implementation mode one: if figure 1 As shown, the TiB of this embodiment 2 The preparation method of particle reinforced foamed aluminum / aluminum alloy is:

[0030] (1) Preparation of aluminum / aluminum alloy melt: using industrial pure aluminum as raw material, heat 1200 grams of industrial pure aluminum to 850°C to melt and hold it for 20 minutes to obtain industrial pure aluminum melt;

[0031] (2) Preparation of reaction raw material billet: Potassium fluoroborate and potassium fluorotitanate are used as raw materials, and the molar ratio of potassium fluoroborate to potassium fluorotitanate is 2:1 for batching. After batching, it is mixed in the mixer Homogenize for 1 hour, and press the homogeneously mixed reaction raw material with a pressure of 100 MPa to obtain a reaction raw material billet, which is preheated to 300°C for use;

[0032] (3) Preparation of composite melt: 480 grams of reaction raw material billet obtained in step (2) is added to the industria...

Embodiment approach 2

[0035] Implementation mode two: if figure 1 As shown, the TiB of this embodiment 2The preparation method of particle reinforced foamed aluminum / aluminum alloy is:

[0036] (1) Preparation of aluminum / aluminum alloy melt: using Al-Si12 alloy as raw material, heating 1600 grams of Al-Si12 alloy to 950°C to melt and keep it for 40 minutes to obtain Al-Si12 alloy melt;

[0037] (2) Preparation of reaction raw material billet: Potassium fluoroborate and potassium fluorotitanate are used as raw materials, and the molar ratio of potassium fluoroborate to potassium fluorotitanate is 2:1 for batching. After batching, it is mixed in the mixer Homogenized for 3 hours, and the homogeneously mixed reaction raw materials were pressed with a pressure of 200 MPa to obtain a reaction raw material billet, which was preheated to 500°C for use;

[0038] (3) Preparation of composite melt: Add 1400 grams of the reaction raw material blank obtained in step (2) to the Al-Si12 alloy melt obtained in...

Embodiment approach 3

[0041] Implementation mode three: if figure 1 As shown, the TiB of this embodiment 2 The preparation method of particle reinforced foamed aluminum / aluminum alloy is:

[0042] (1) Preparation of aluminum / aluminum alloy melt: using ZL111 alloy as raw material, heating 1300 grams of ZL111 alloy to 900°C to melt and keep it warm for 30 minutes to obtain ZL111 alloy melt;

[0043] (2) Preparation of reaction raw material billet: Potassium fluoroborate and potassium fluorotitanate are used as raw materials, and the molar ratio of potassium fluoroborate to potassium fluorotitanate is 2:1 for batching. After batching, it is mixed in the mixer Homogenized for 2 hours, and the homogeneously mixed reaction raw materials were pressed with a pressure of 150 MPa to obtain a reaction raw material billet, which was preheated to 400°C for use;

[0044] (3) Preparation of composite melt: Add 700 grams of the reaction raw material billet obtained in step (2) to the ZL111 alloy melt obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com