A method for improving graphite grade of thick and large section gray cast iron

A large-section, gray cast iron technology, applied in the grade field, can solve the problems of improving the graphite grade of thick and large-section gray cast iron, and does not use the thermal conductivity and heat storage coefficient of chrome ore sand, so as to overcome shrinkage defects, improve mechanical properties, and improve Effect of Graphite Grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

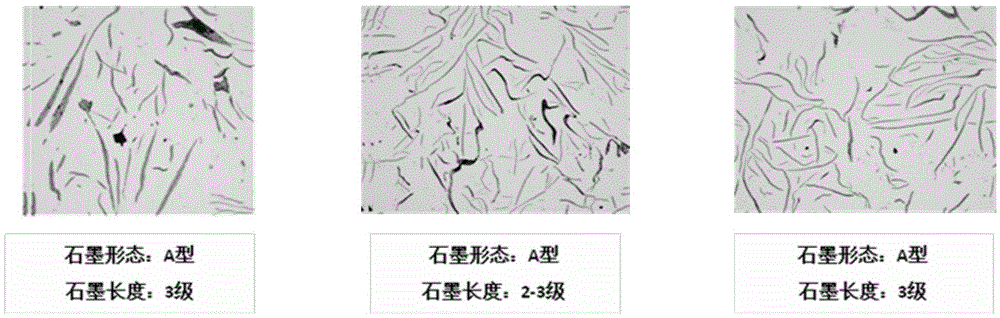

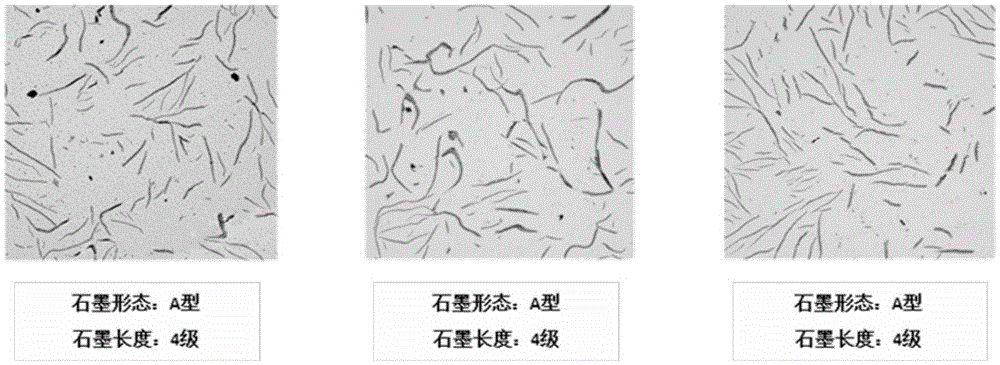

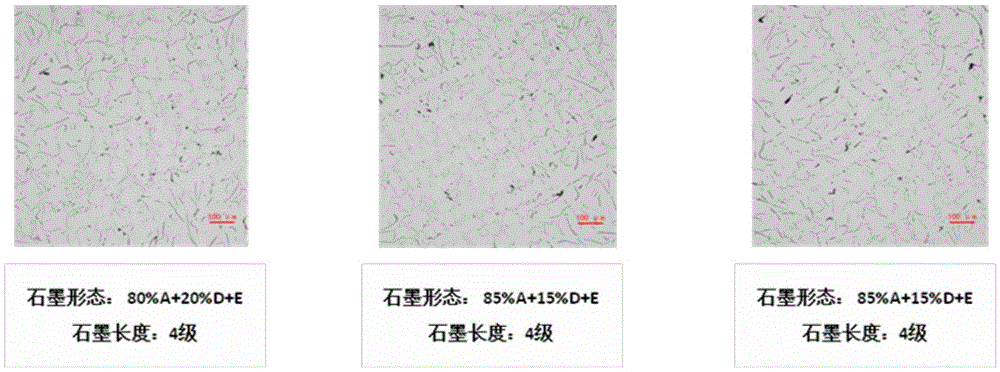

Image

Examples

Embodiment Construction

[0028] A method for improving the graphite grade of thick and large section gray cast iron, which comprises the following steps

[0029] a. Size selection of thick and large section castings:

[0030] Since castings with a wall thickness exceeding 60mm can be classified as thick and large-section castings, the size of the thick and large-section castings selected this time is 150mm*150mm*450mm.

[0031] b. Choice of cooling method: According to different cooling speeds, three cooling methods are selected: natural cooling, chrome ore sand cooling and direct cooling chilled iron cooling

[0032] Parameter comparison

main content

silica sand

silica

slow

slow

Chrome ore

medium

medium

Direct cooling cold iron

Iron compounds

quick

quick

[0033] c. Material ratio: pig iron contains a large number of cores, and these cores have a great effect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com