Environment-friendly white printing ink for printing of POF thermal contraction film and preparation method of white printing ink

A technology of white ink and heat shrinkable film, applied in the field of ink, can solve the problem of low adhesion fastness, and achieve the effect of good adhesion fastness, strong abrasion resistance and smoothness, and excellent transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

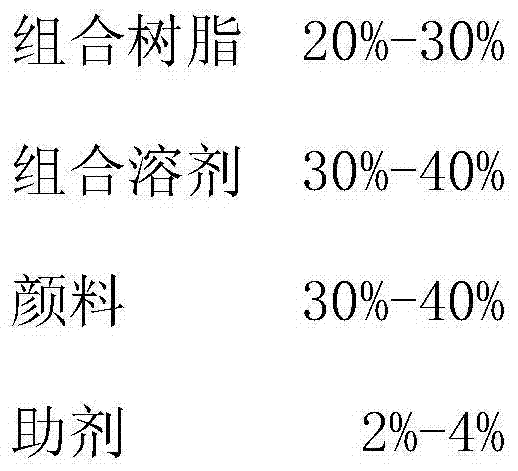

[0037] An environmentally friendly white ink for POF heat shrinkable film printing, consisting of the following components in mass percentage:

[0038]

[0039]

[0040] Its preparation method is as follows: after weighing the raw materials according to the above ratio, mix them evenly in the mixing tank except gas phase silica, put them into a sand mill for grinding, stop grinding when the fineness reaches below 15 μm, adjust the ink and add Fumed silica, adjust the viscosity to reach the 35-40s of the 4# cup, filter, that is, the obtained ink is "Product A".

Embodiment 2

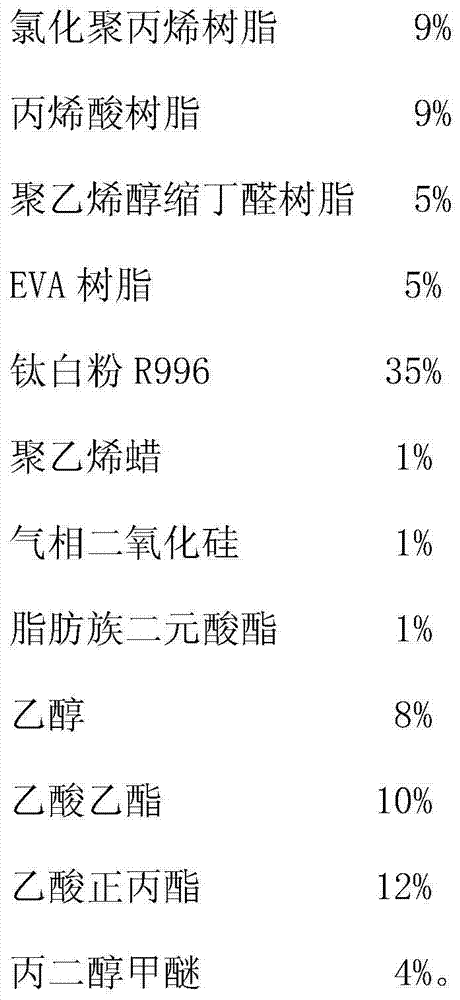

[0042] An environmentally friendly white ink for POF heat shrinkable film printing, consisting of the following components in mass percentage:

[0043]

[0044]

[0045] The preparation method is the same as in Example 1, and the obtained ink is "Product B".

Embodiment 3

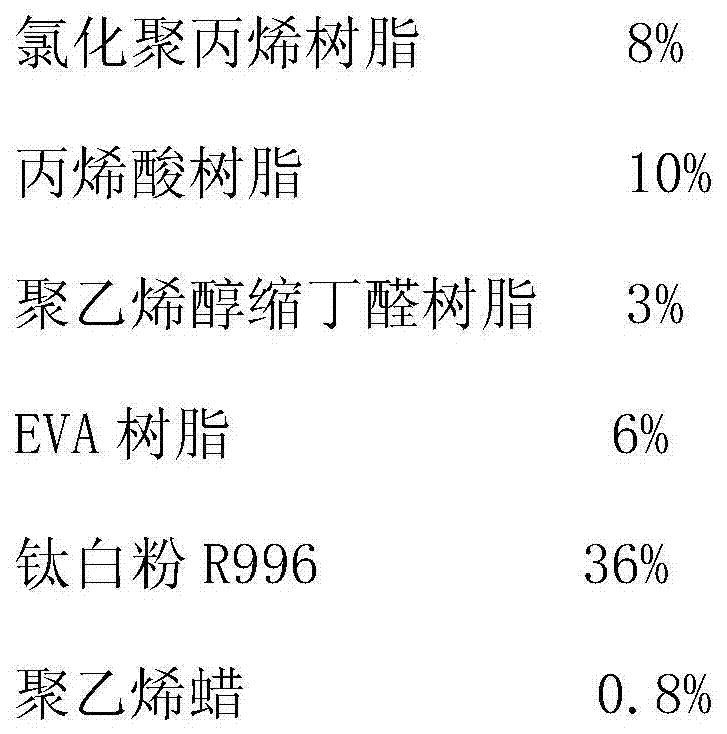

[0047] An environmentally friendly white ink for POF heat shrinkable film printing, consisting of the following components in mass percentage:

[0048]

[0049] The preparation method was the same as in Example 1, and the obtained ink was "Product C".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com