Purifying method of shrimp tropomyosin

A technology of tropomyosin and purification methods, which is applied in the direction of animal/human peptides, peptide sources, peptides, etc., can solve the problems of difficult sample recovery, expensive consumables, and low sample purity, which is conducive to large-scale production and reduces production The effect of high cost and protein purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

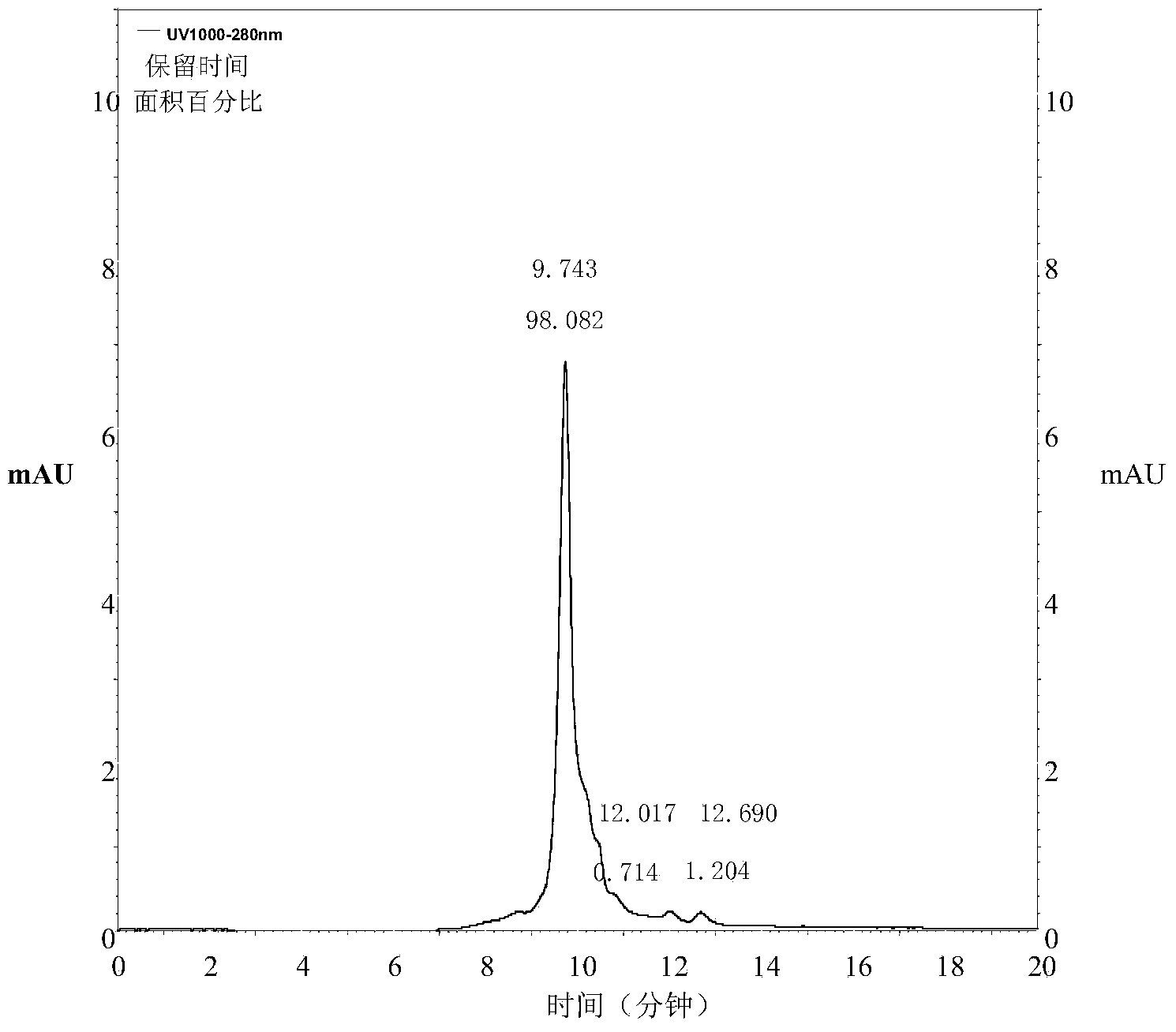

Embodiment 1

[0031] (1) Preparation of crude shrimp tropomyosin:

[0032] ①Take 100g of Litopenaeus vannamei with heads, shells and guts removed, add 1000mL of 0.9% sodium chloride solution, and homogenate; 7.5. In Tris-HCl buffer solution with a concentration of 20mmol / L, wherein the Tris-HCl buffer solution with a concentration of 20mmol / L contains 50mmol / L KCl. After centrifugation at 4000×g, the supernatant was discarded and the precipitate was collected. The precipitate was redissolved in Tris-HCl buffer solution with a pH value of 7.5 and a concentration of 20 mmol / L, and the precipitate was collected by centrifugation, and repeated 3 times.

[0033] ②Add 400 times the volume of cold acetone 200mL pre-cooled at -20°C overnight to the above precipitate, seal the seal, mix thoroughly with a magnetic stirrer at 0°C for 30min, centrifuge at 4000×g for 10min, collect the precipitate, and repeat After the "mixing-centrifugation" step twice, the precipitate was transferred to a clean filt...

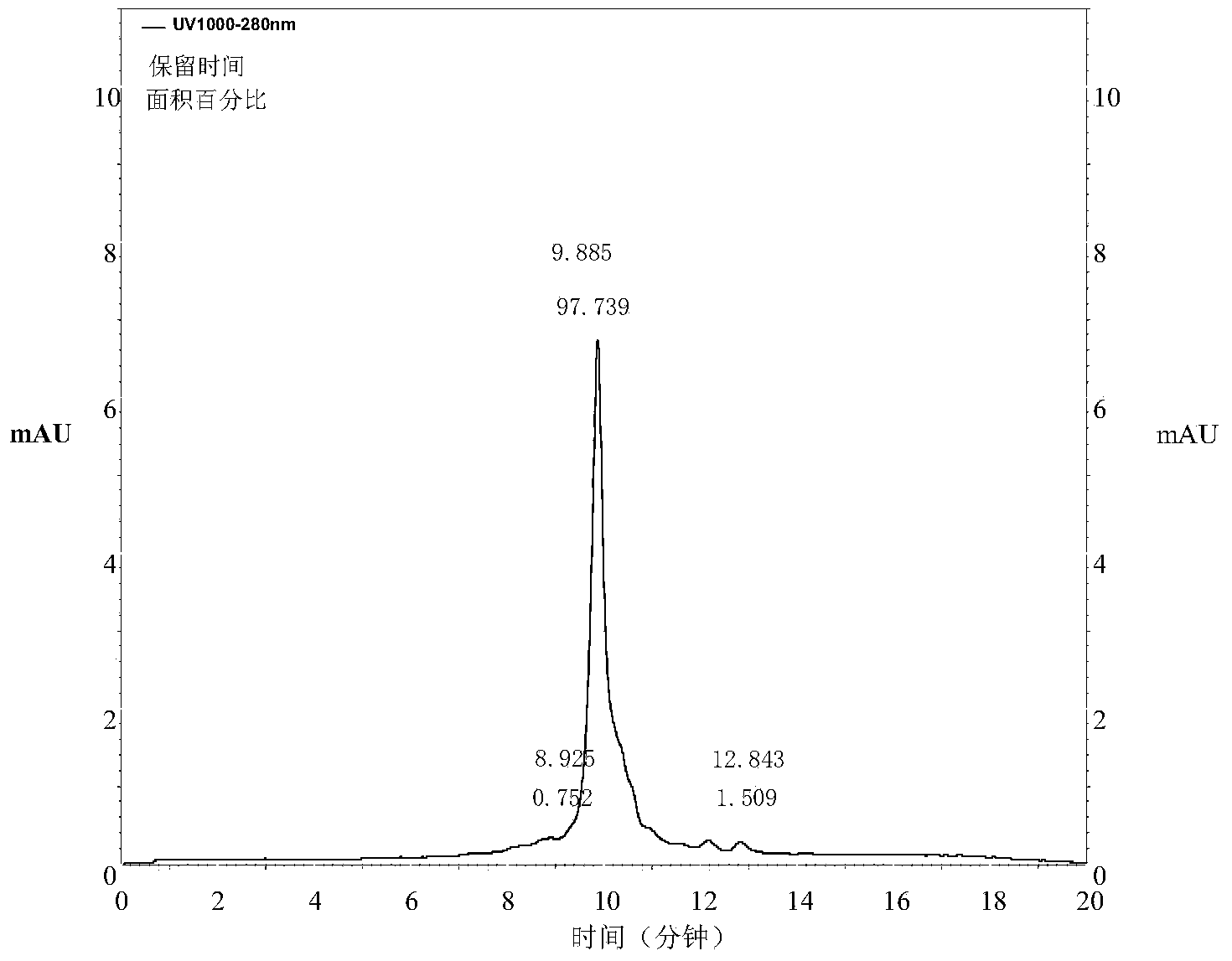

Embodiment 2

[0044] (1) Preparation of crude shrimp tropomyosin:

[0045] ①Take 100g of Litopenaeus vannamei with heads, shells and guts removed, add 1000mL of 0.9% sodium chloride solution, homogenate, add 1000mL at a concentration of 20mmol / L, 1:10 (m / v), pH value is 7.5 in Tris-HCl buffer solution containing 50mmol / L KCl, centrifuged at 4000×g, discard the supernatant, redissolve the precipitate in the above buffer solution, collect the precipitate by centrifugation, repeat 3 times.

[0046] ②Add 400 times the volume of cold acetone 200mL pre-cooled at -20°C overnight to the above precipitate, seal the seal, mix thoroughly with a magnetic stirrer at 0°C for 30min, centrifuge at 4000×g for 10min, collect the precipitate, and repeat After the steps of "mixing-centrifugation" twice, the precipitate was transferred to a clean filter paper, and air-dried at room temperature to obtain shrimp fibrin acetone powder, about 10 g.

[0047] ③Take 5 g of shrimp fibrin acetone powder, add 75 mL of d...

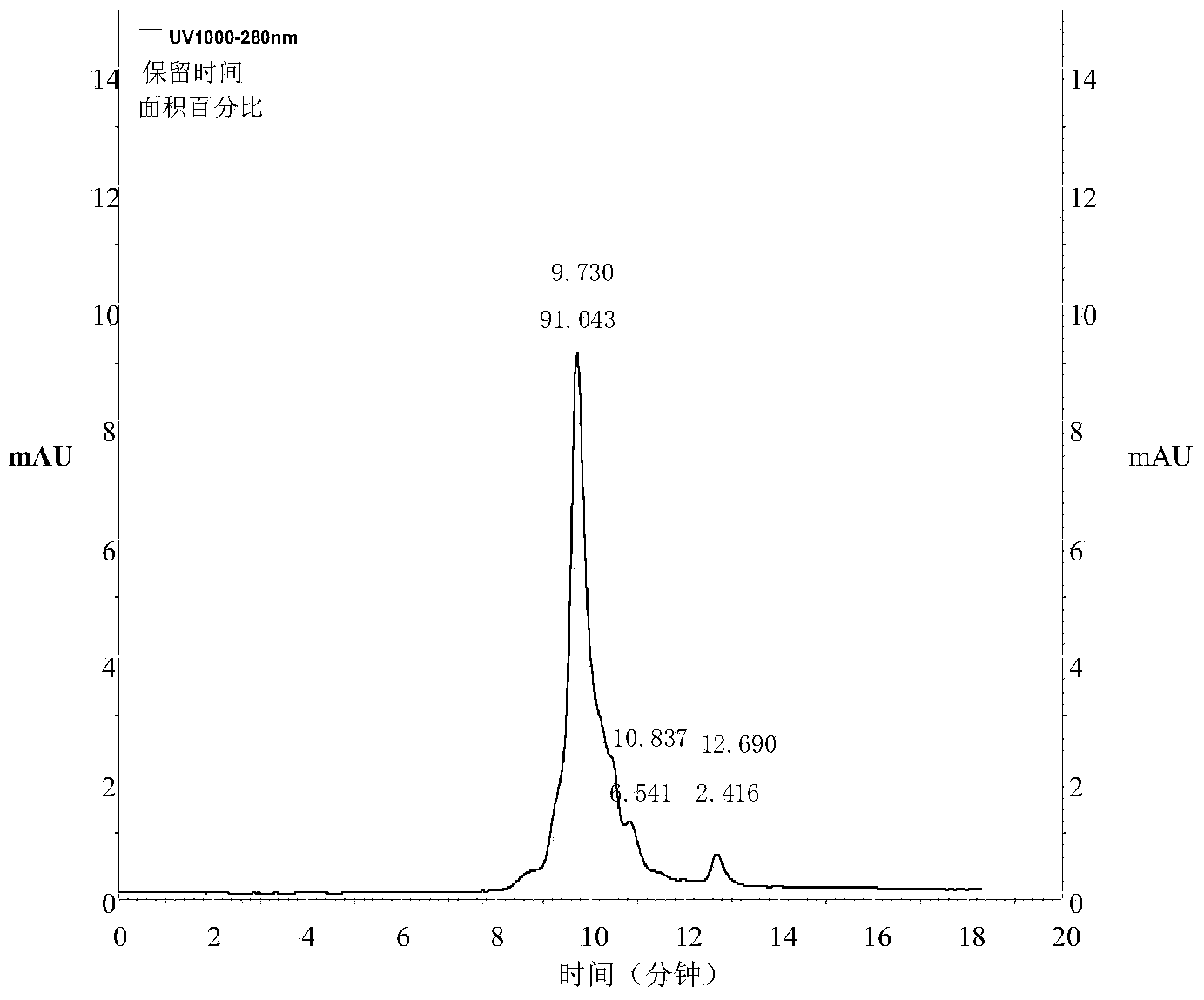

Embodiment 3

[0056] (1) Preparation of crude shrimp tropomyosin:

[0057] ①Take 100g of Litopenaeus vannamei with head, shell and gut removed, add 1000mL of sodium chloride solution with a concentration of 0.9%, homogenate, add 1000mL with a concentration of 20mmol / v at 1:10(m / v) L. The pH value is 7.5 in Tris-HCl buffer solution containing 50mmol / L KCl. Centrifuge at 4000×g, discard the supernatant, redissolve the precipitate in the above buffer solution, collect the precipitate by centrifugation, and repeat 3 times.

[0058] ②Add 400 times the volume of cold acetone 200mL pre-cooled at -20°C overnight to the above precipitation, seal the seal, and mix thoroughly with a magnetic stirrer at 0°C for 30min. Centrifuge at 4000×g for 10 min to collect the precipitate, repeat the “mixing-centrifugation” step twice, then transfer the precipitate to a clean filter paper, and air-dry at room temperature to obtain shrimp fibrin acetone powder, about There are 10g.

[0059] ③Take 5 g of shrimp fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com