Low-energy-consumption and ultraclean-emission flue gas desulfurization method and device

A desulfurization device and low energy consumption technology, which is applied in the field of flue gas pollution treatment and power plant flue gas desulfurization, can solve the problems of low quality of desulfurization by-product gypsum, low desulfurization efficiency, and high energy consumption in operation, so as to improve the purity of gypsum and improve the quality of slurry The effect of density and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following non-limiting examples illustrate the invention.

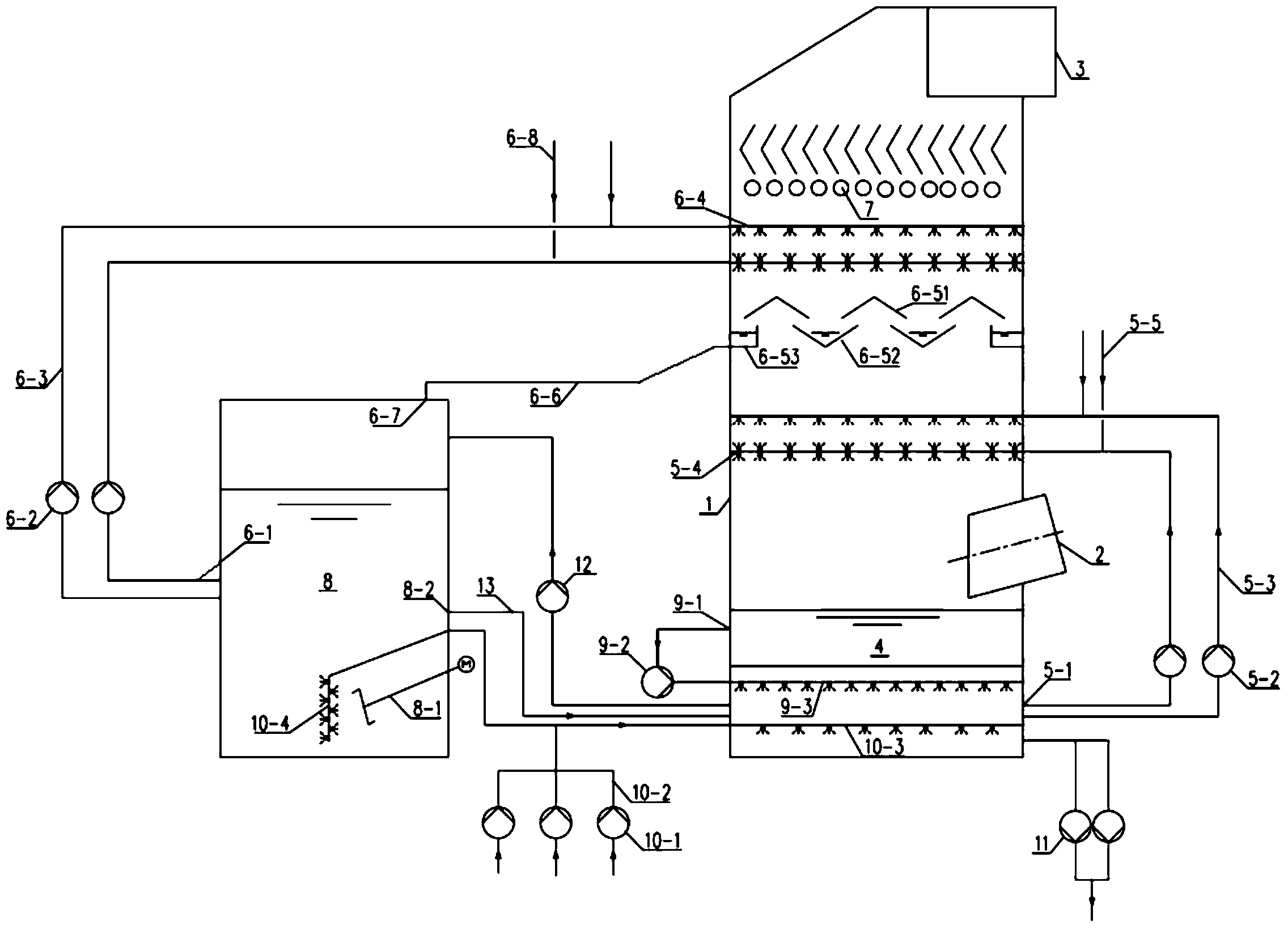

[0041] refer to figure 1 Shown:

[0042] 1. Flue gas line:

[0043] A roof-type gas-liquid splitter 6-5 is arranged between the spray layers of the absorption tower 1, and the roof-type gas-liquid splitter 6-5 is composed of a splitter ridge 6-51, a liquid collection tank 6-52 and a confluence tank 6-53, The distribution ridges 6-51 and the liquid collection grooves 6-52 are arranged in a staggered manner in the form of positive and negative mirror images. The splitter ridge 6-51 is arranged horizontally, and the liquid collection tank 6-52 and the confluence tank 6-53 are inclined toward the slurry outlet to prevent the solids in the desulfurization slurry from depositing in the liquid collection tank and the confluence tank. Angle 3-15°. The sprayed slurry forms a liquid film between the distribution ridge 6-51 and the sump 6-52.

[0044] The flue gas enters the absorption tower 1 from the flue gas i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com