Rotary streamline production method of junction boxes

A flow production and junction box technology, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of labor consumption, long time intervals, and long distances of accessories, so as to reduce operators and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

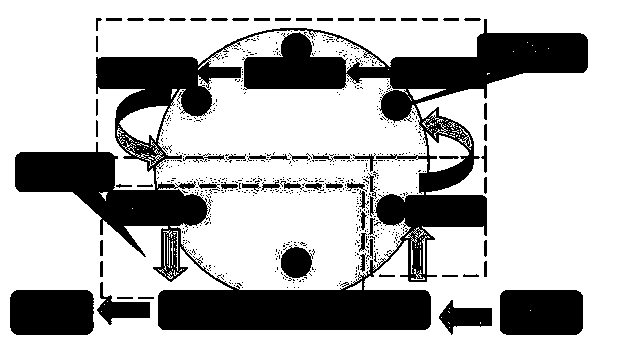

[0014] A rotary production method for a junction box:

[0015] A. Take an unwelded raw material and put it into the fixture;

[0016] B. The running water turntable rotates, and the raw materials enter the next station for ultrasonic welding of the junction box;

[0017] C. The running water turntable rotates, and the raw materials enter the next station for dispensing of the junction box;

[0018] D. The running water turntable rotates, and the raw materials enter the next station for the detection of the junction box;

[0019] E. If the test is unqualified, repeat the test three times, if it is still unqualified, stop the machine;

[0020] F. The test is qualified, the water turntable rotates, the raw material enters the next station, and the welding is manually taken out from the turntable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com