Automatic imaging monitoring system and method for mold clamping and injection molding operations

A monitoring system and technology in operation, applied in the field of automatic control of injection molding machines, can solve problems such as damage to molds, and achieve the effect of reducing operators, reducing production costs, and improving operating speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

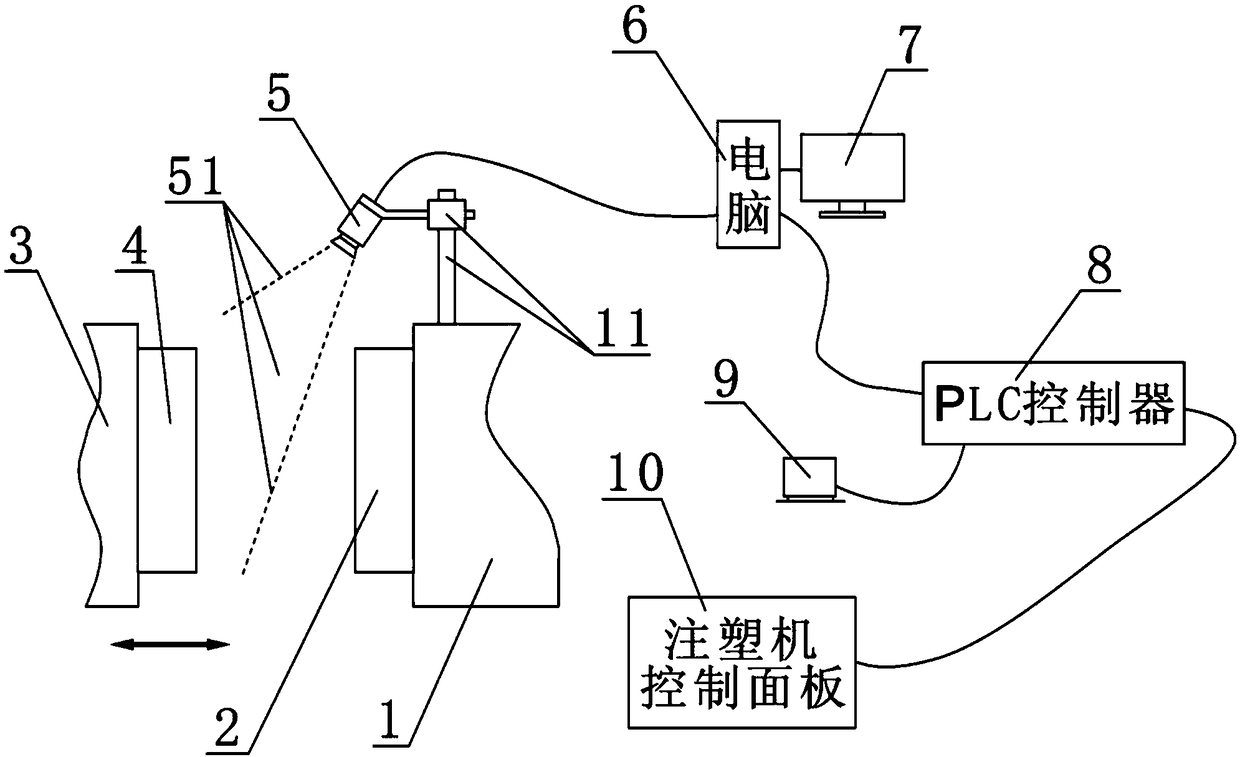

[0022] Such as figure 1 As shown, an automatic imaging monitoring system used in mold clamping and injection molding operations, including injection molding machine fixed template 1, moving template 3, camera device 5, computer 6, PLC controller 8, alarm 9 and injection molding machine control panel 10. A fixed mold 2 is installed on the fixed template 1 of the injection molding machine, and a movable mold 4 corresponding to the fixed mold 2 for mold closing operation is installed on the movable template 3; The camera device 5 corresponding to the mold 2, the camera device 5 is used to carry out real-time video recording and image acquisition to the movable mold 4 and the fixed mold 2 clamping operation process; The recorded data and the collected image information are transmitted to the computer 6. The computer 6 has an image comparison processing module, and the computer 6 stores the base map database of the moving mold 4 and the fixed mold 2 in place. The base map database ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com