Large-connecting-rod two-grade buffering shock absorber

A shock absorber and connecting rod technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problem of shock absorbers that cannot adapt to large connecting rods, prone to vacuum areas, and increased compression damping and other problems, to avoid gas-oil mixing phenomenon, better lubricating effect, and improve shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

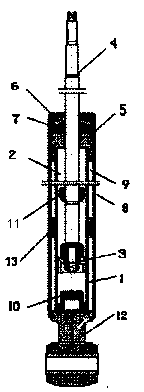

[0014] Such as figure 1 As shown, a large connecting rod two-stage buffer shock absorber includes an inner working cylinder, a piston assembly in the inner working cylinder, shock absorbing oil, an inert gas, a piston rod on the piston, and a guide on the upper part of the inner working cylinder, guiding The upper end of the device is provided with a sealed dust cover and a sealing ring, and the piston rod is also provided with a piston buffer block. The piston buffer block is in a cylindrical structure, and there is a gap between the piston buffer block and the inner wall of the inner working cylinder. It is characterized in that: The outer wall of the piston is inlaid with steel balls for guiding and positioning. An air guide channel is provided between the inside and the outside of the cylindrical structure of the piston buffer bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com