Steel tube tower column with reinforcing structures on inner wall and manufacturing method thereof

A technology for strengthening structures and columns, applied to structural elements, building reinforcements, towers, etc., can solve problems such as inconvenient maintenance, transportation and construction, and achieve the effects of improving production efficiency, reducing construction costs, and being easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] In the steel pipe tower column of the present invention, the column body can be formed by rolling a flat steel plate, or by winding a flat steel strip according to a helical angle.

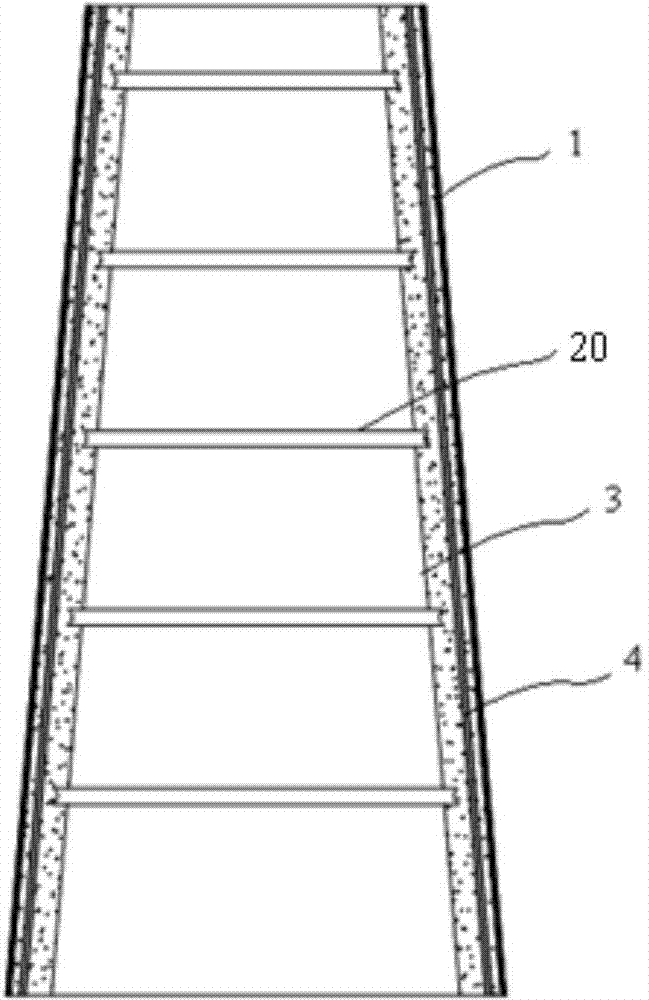

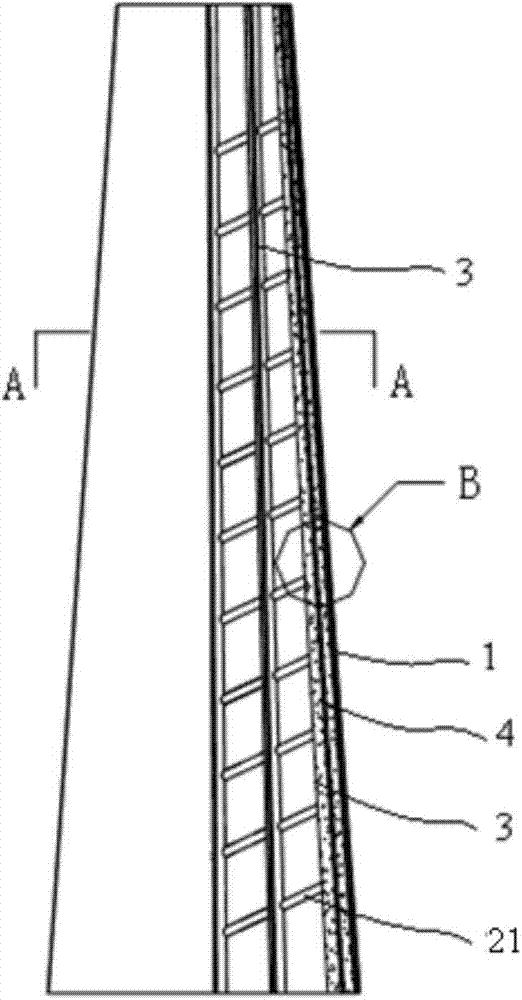

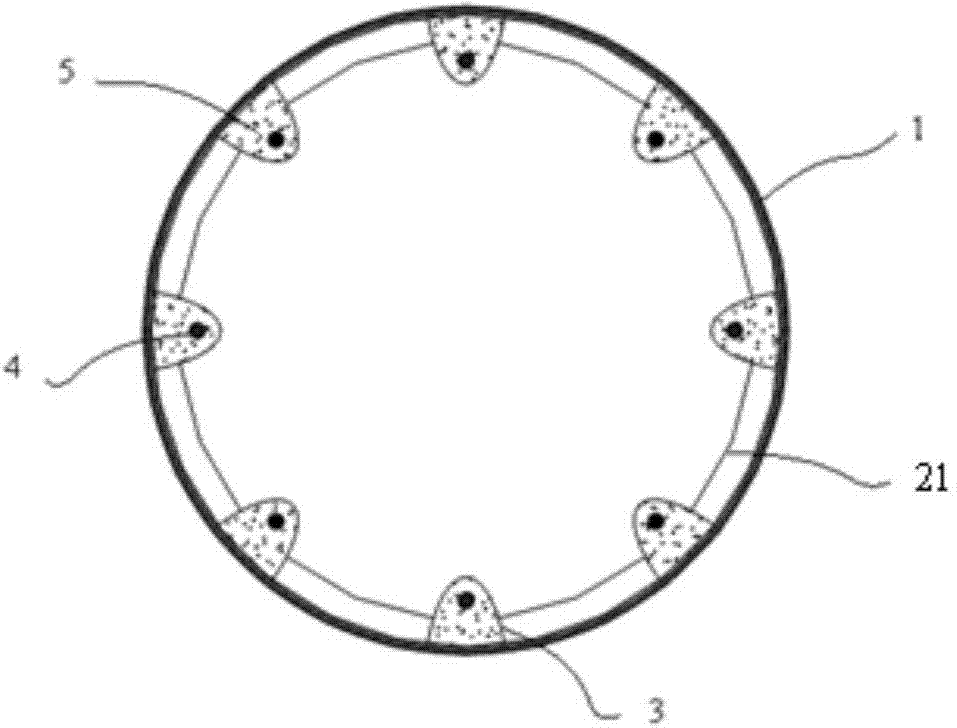

[0027] In order to improve the overall mechanical performance of the column, we set criss-cross reinforcement structures on the pipe wall, specifically: the inner wall 1 of the tower column is provided with a number of independent annular reinforcement ribs 20 along the circumference (such as figure 1 ) or continuous spiral ribs 21 (such as Figure 2-5 ), the inner wall 1 of the tower column between the annular reinforcing rib 20 or the spiral reinforcing rib 21 is provided with reinforcing columns 3 at intervals along the axial direction. The purpose of setting the ring-shaped or helical reinforcing rib above is to widen the pipe diameter length (Dn≥3600m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com