DMF (dimethyl formamide) waste gas water-washing recycling device and method for manufacturing of copper-clad plates

A recycling device and a technology for copper clad laminates, which are applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of explosive resources, cannot be recycled, and large equipment, so as to achieve good impact resistance and improve efficiency. , the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

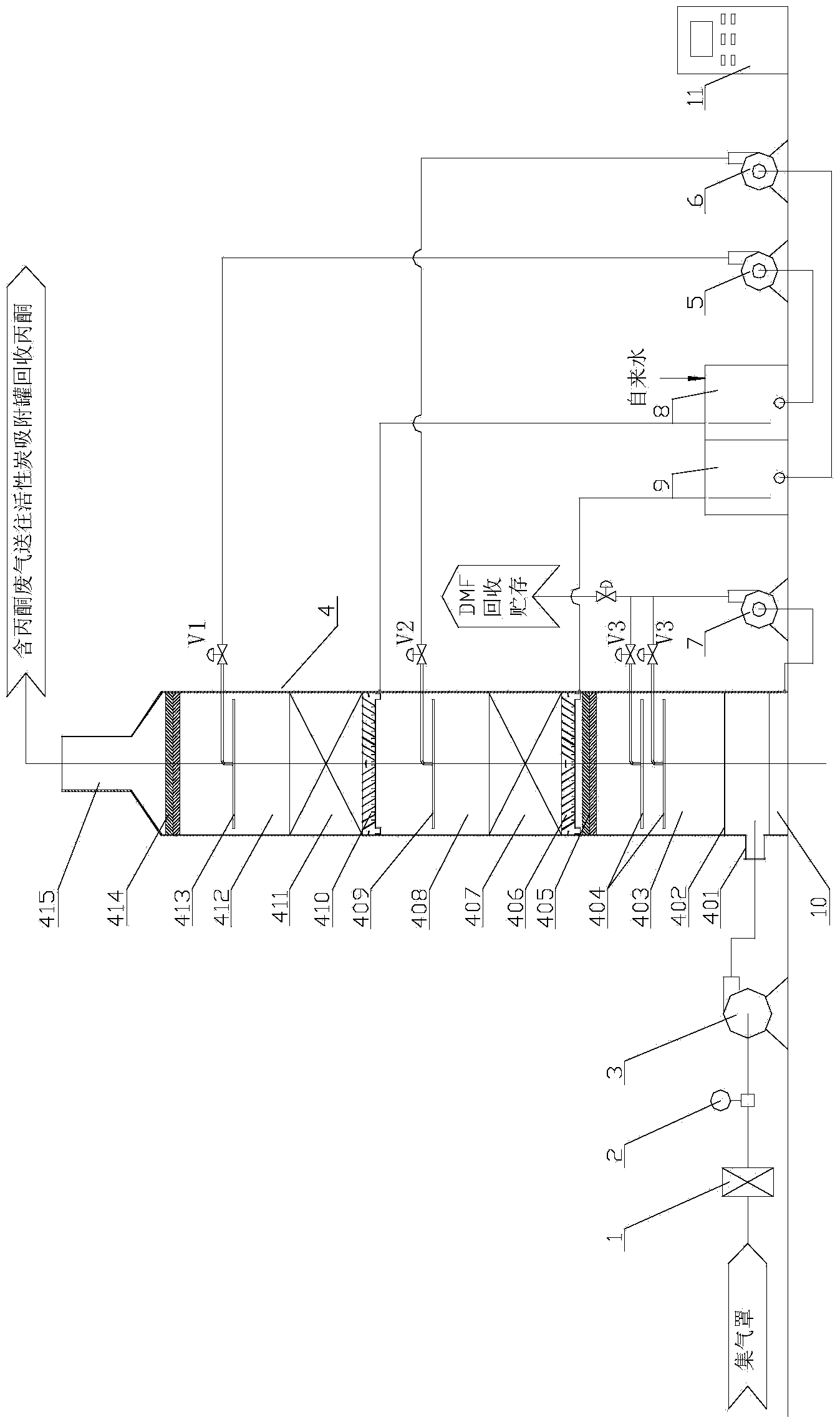

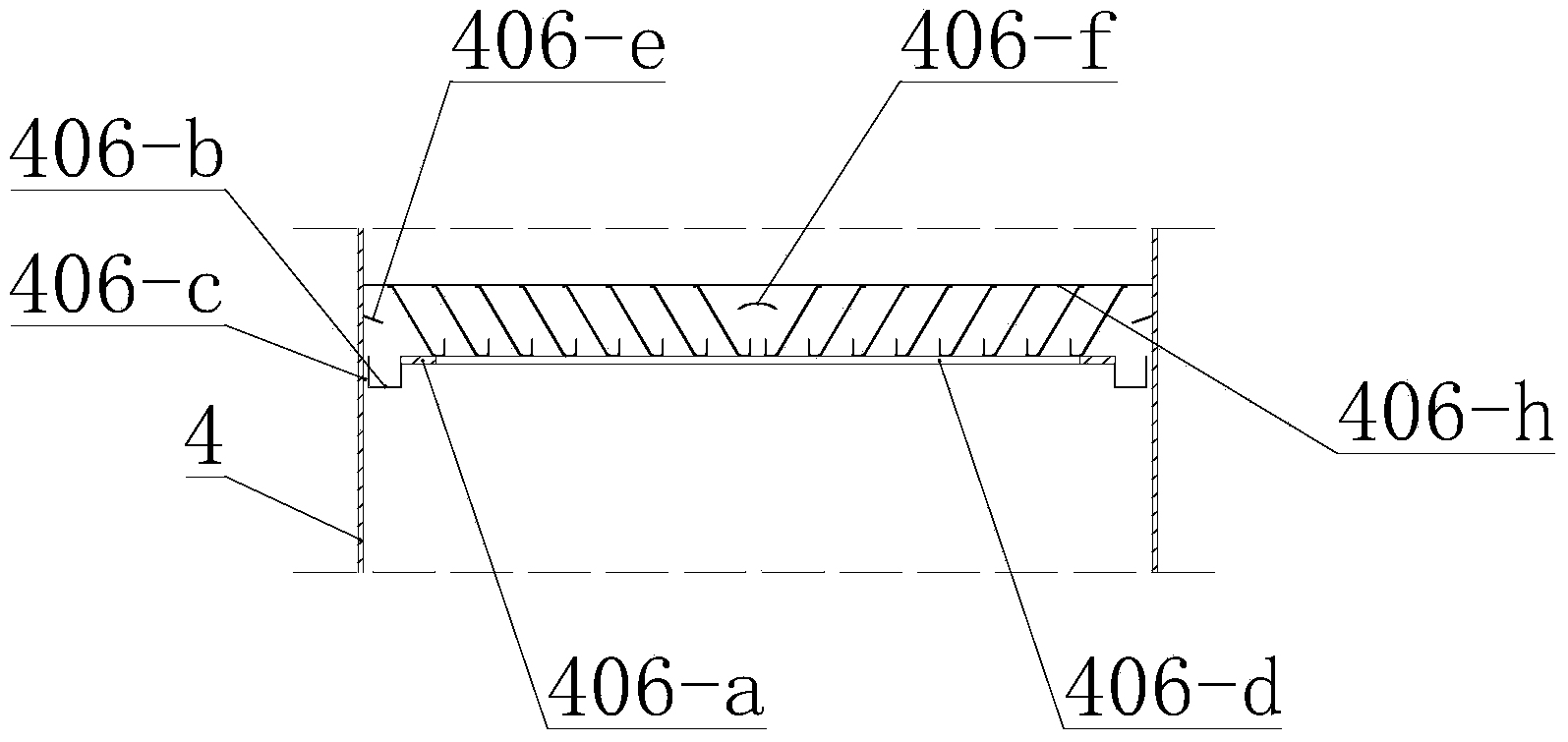

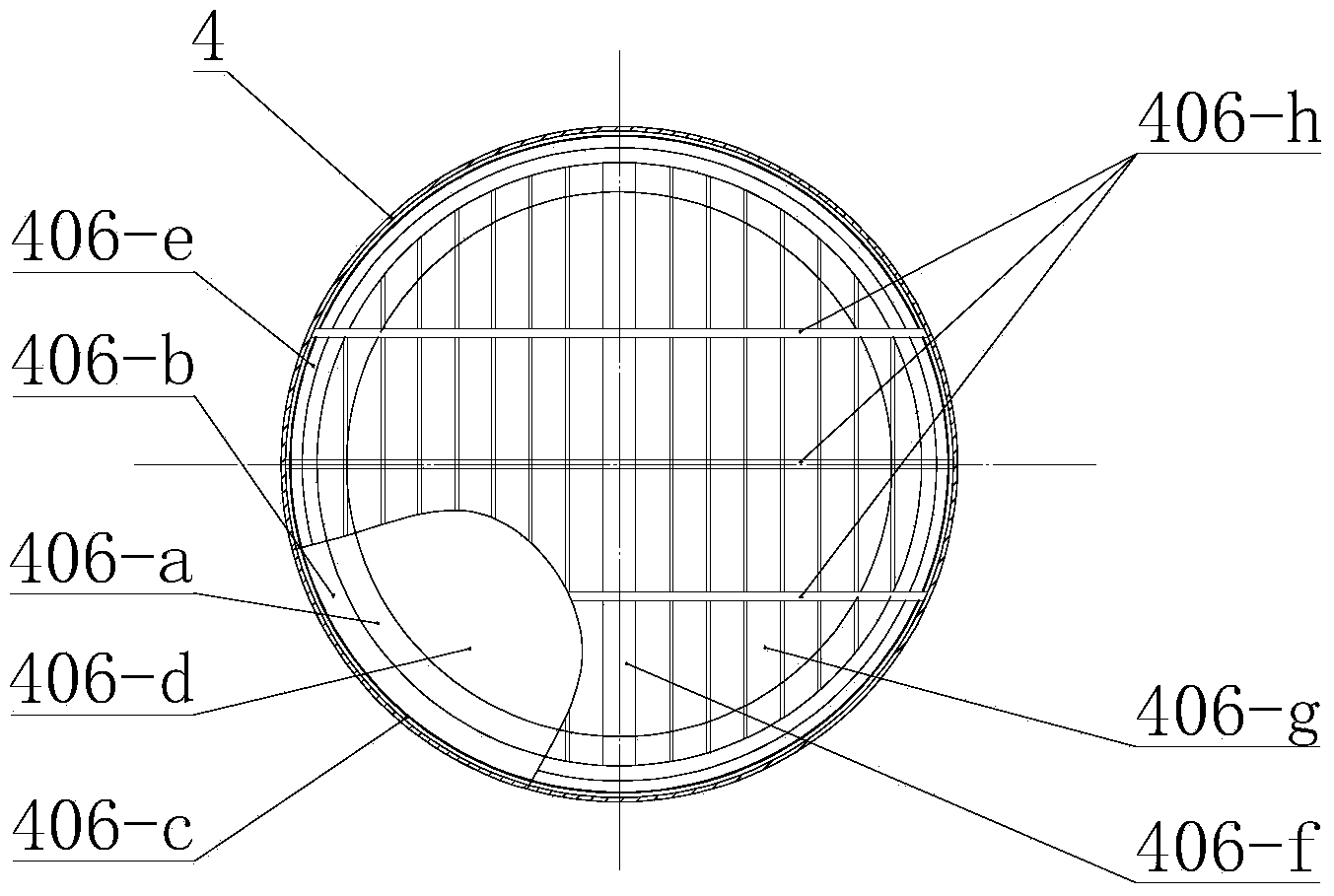

[0026] refer to figure 1 , DMF waste gas washing recovery device for copper clad laminate manufacturing, including filter 1, flow meter 2, fan 3, water washing tower 4, first circulating water pump 5, second circulating water pump 6, third circulating water pump 7, first circulating liquid Storage tank 8, second circulating liquid storage tank 9, third circulating liquid storage tank 10 and control system 11, filter 1 is connected to flow meter 2, flow meter 2 is connected to fan 3, fan 3 is connected to washing tower 4, and the third circulating liquid The storage tank 10 is located at the bottom of the water washing tower 4, and the water washing tower 4 includes from bottom to top: air inlet 401, orifice uniform air plate 402, third spray chamber 403, third sprayer 404, second defogger Device 405, second tray 406, second packing layer 407, second spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com