Device and method for frequency conversion control of stone cutting motor

A stone cutting and frequency conversion control technology, which is applied in the direction of AC motor control, control system, stone processing tools, etc., can solve the problems of unable to detect the real-time torque of the spindle motor, saw blade stuck in the stone, power grid production accidents, etc., to achieve high efficiency High, time-compact and intelligent operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

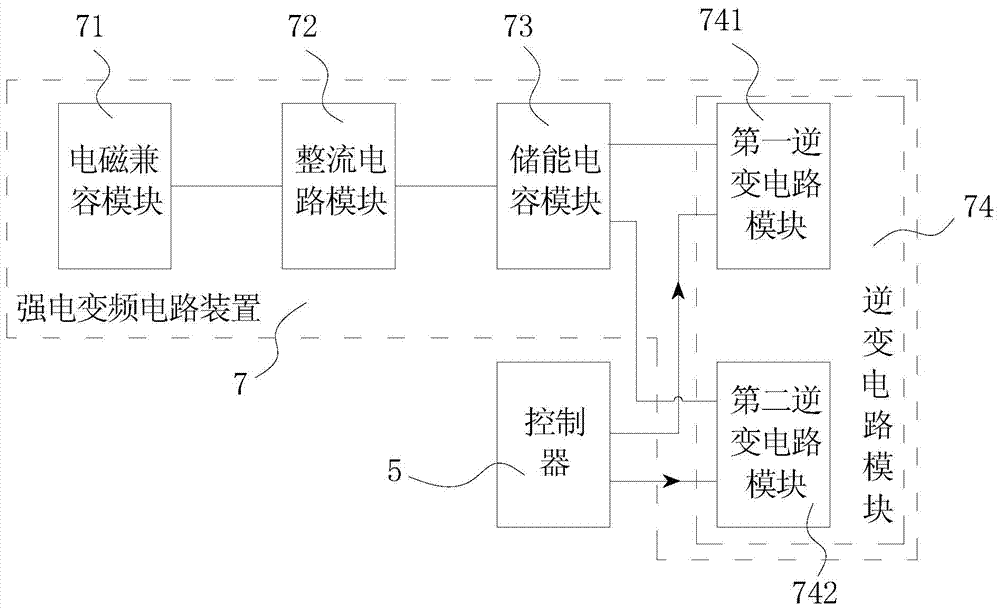

[0049] refer to Figure 5 As described, the functions and effects of this embodiment are basically the same as those of the embodiment, the difference being that in this embodiment, the data receiving module 52 and the data processing module 53 of this embodiment are combined into a CPU module 14, and the CPU module 14 adopts STMicroelectronics company For the STM32F103ZET6 chip produced, the power supply of the CPU module 14 is supplied with a 3.3V DC voltage by a REG1117-3.3 low voltage regulator. Wherein, the pins 43, 46, 47, 98, 97, 96, and 42 of the CPU module 14 are respectively connected to the U-phase IGBT reverse input terminal and the V-phase IGBT reverse input terminal of the second drive circuit module 542 controlling the lifting motor 9. terminal, W-phase IGBT reverse input terminal, W-phase IGBT forward input terminal, V-phase IGBT forward input terminal, U-phase IGBT forward input terminal and IGBT abnormal output terminal; 59, 60, 63, 64 of CPU module 14 , 65,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com