Germanium material surface stabilizing and passivating method

A stable and passivation technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of reducing and unfavorable Ge material application, and achieve the effect of convenient use, obvious passivation effect and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The thiol used for passivation in this embodiment is n-dodecanethiol (molecular formula CH 3 (CH 2 ) 10 CH 2 SH, the English abbreviation is NDM), and the crystal orientation of the Ge sheet to be passivated is (111).

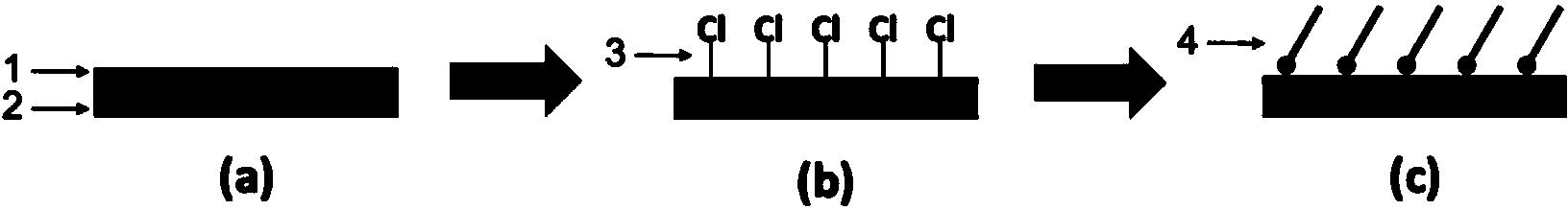

[0031] Such as figure 1 shown, including the following steps:

[0032] Step 1: Cut the Ge sheet with the crystal orientation of (111) into small pieces of 5 mm×5 mm, and then soak the Ge sheet in acetone and ethanol solutions for 15 minutes and ultrasonically clean the Ge sheet to remove organic pollutants on the surface of the Ge sheet. After ultrasonic cleaning, each sample piece was blown dry with nitrogen gas for later use.

[0033] Step 2: soak the Ge sheet after the surface cleaning treatment in step 1 into deionized water for 30min, and initially remove the water-soluble oxide (such as GeO2) on the surface of the Ge sheet. 2 ). Then soak the Ge sheet in a hydrochloric acid solution with a mass percentage of 10% for 30 minutes to further re...

Embodiment 2

[0042] The thiol used for passivation in this embodiment is n-hexadecanthyl mercaptan (molecular formula CH 3 (CH 2 ) 15 SH), and the crystal orientation of the Ge sheet to be passivated is (111).

[0043] Such as figure 1 shown, including the following steps:

[0044] Step 1: Removing organic pollutants on the surface of the Ge sheet, the specific process is consistent with Step 1 in Example 1.

[0045] Step 2: removing the oxide layer on the surface of the Ge sheet and realizing surface chlorination, the specific process is consistent with step 2 in Example 1.

[0046] Step 3: Prepare 10 mL of n-hexadecanethiol solution with a concentration of 2 ammol / L in absolute ethanol, mix well and add 10 mL of deionized water to the solution. To ensure that the reagents are well mixed, mix the reagents thoroughly with a shaker until the white suspension in the mixed reagents disappears. The finally obtained reaction reagent is ammol / L n-hexadecanthiol solution (prepared with eth...

Embodiment 3

[0050] The mercaptan that is used for passivation in this embodiment is n-octadecyl mercaptan (molecular formula CH 3 (CH 2 ) 17 SH), and the crystal orientation of the Ge sheet to be passivated is (111).

[0051] Such as figure 1 shown, including the following steps:

[0052] Step 1: Removing organic pollutants on the surface of the Ge sheet, the specific process is consistent with Step 1 in Example 1.

[0053] Step 2: removing the oxide layer on the surface of the Ge sheet and realizing surface chlorination, the specific process is consistent with step 2 in Example 1.

[0054] Step 3: Prepare 10 mL of n-octadecylmercaptan solution with a concentration of 2 ammol / L with absolute ethanol, mix well and add 10 mL of deionized water to the solution. To ensure that the reagents are well mixed, mix the reagents thoroughly with a shaker until the white suspension in the mixed reagents disappears. The finally obtained reaction reagent is an ammol / L n-octadecylmercaptan solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com