Front end input waveguide structure of direction coupling optical waveguide detector

A directional coupling, front-end input technology, applied in the coupling, light guiding, optics and other directions of optical waveguides, can solve the problems of weak propagation direction, uneven photocurrent distribution of waveguide detectors, uneven photocurrent distribution, etc., to increase the photocurrent , Overcome the shortcomings of the horizontal coupling waveguide detector, and solve the effect of overheating and burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

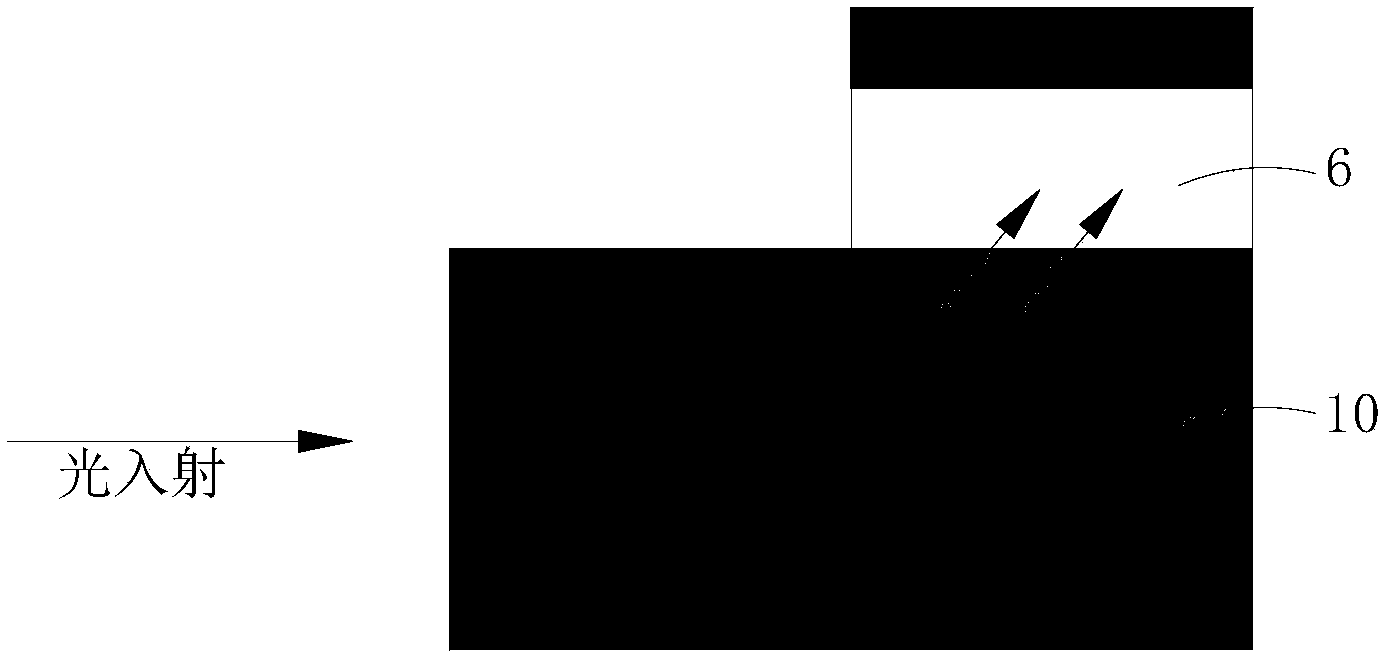

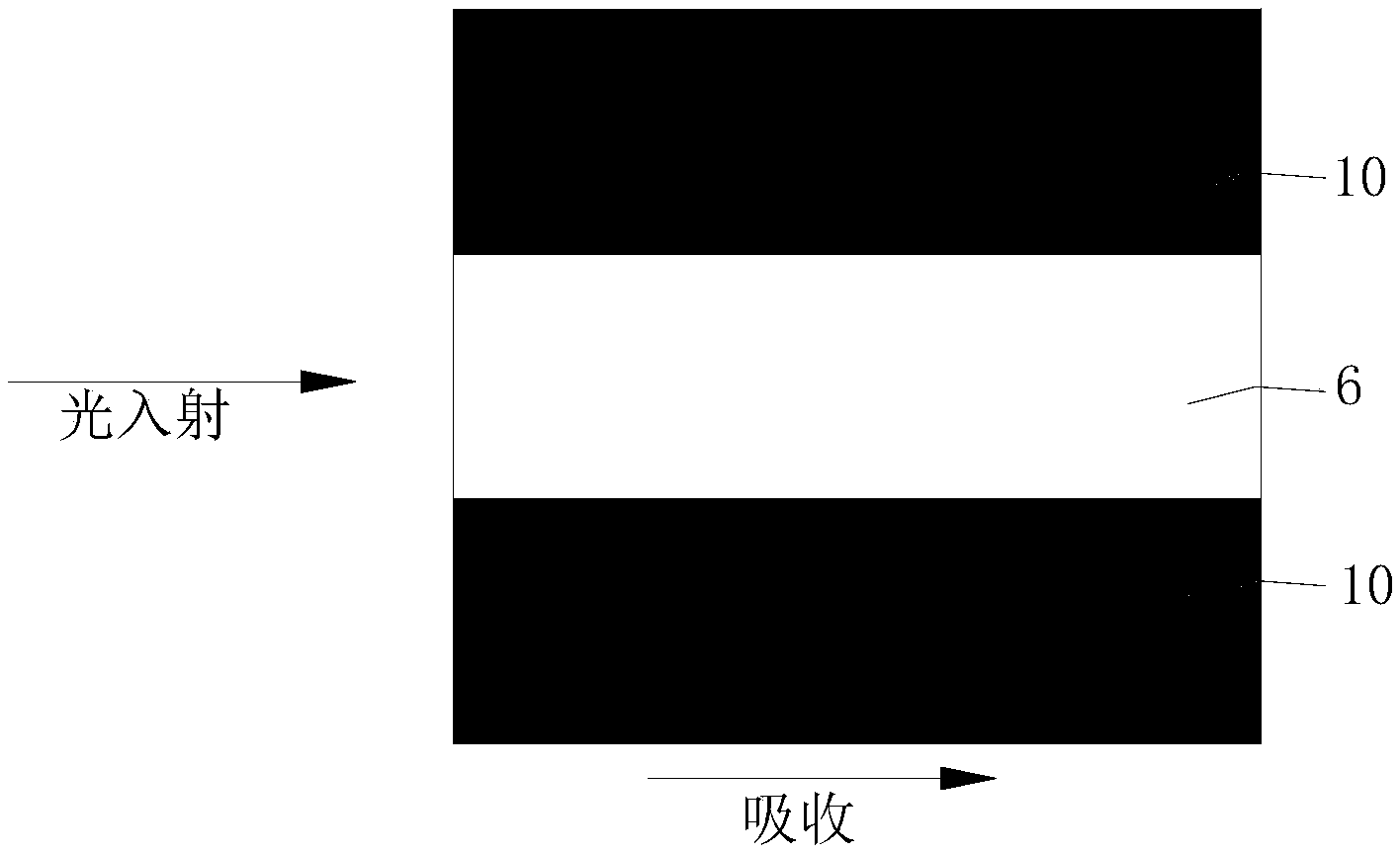

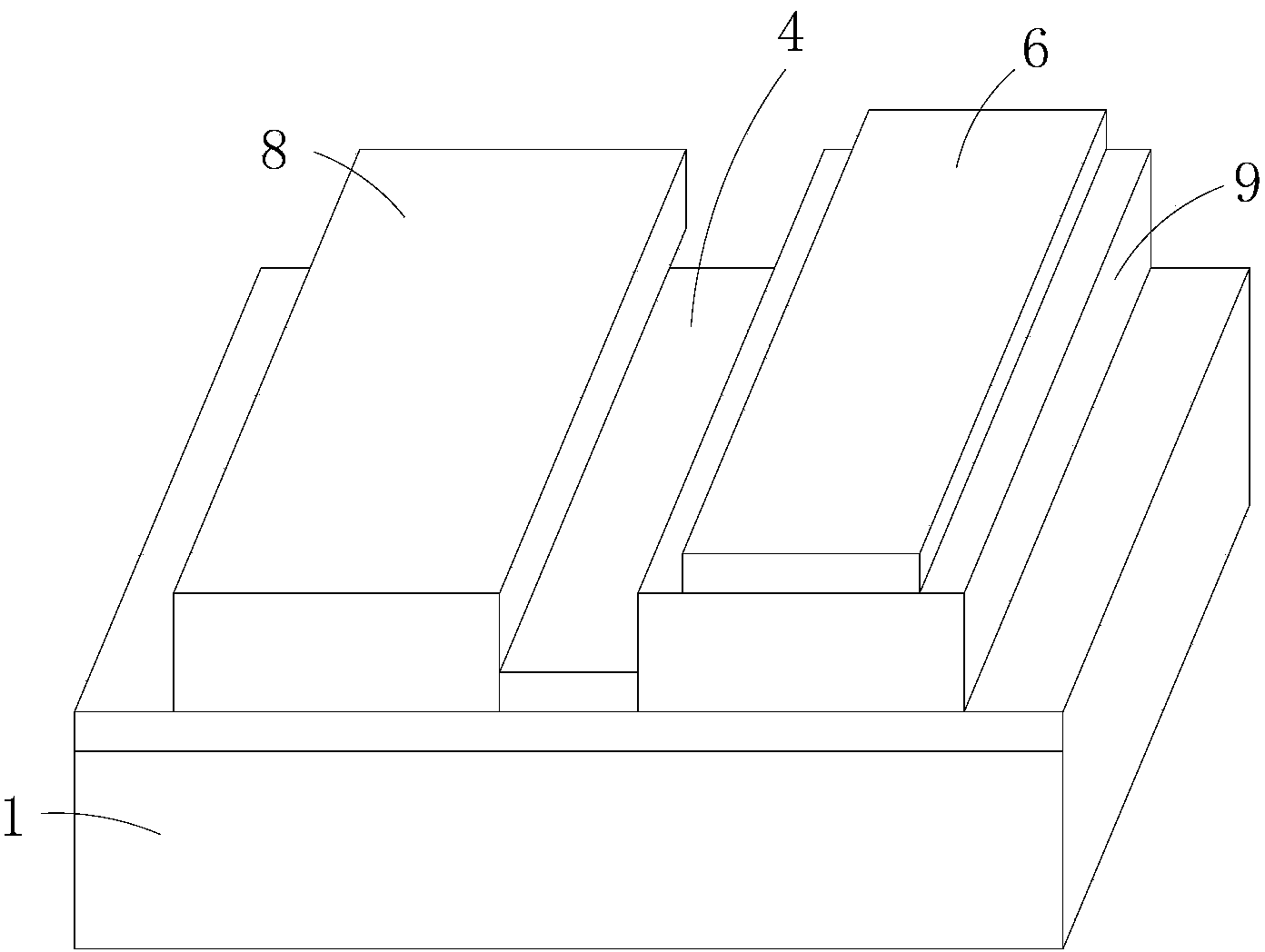

[0027] Embodiment: The following is the working wavelength of 1.55 μm, the material InGaAs (indium gallium arsenide) of the absorption layer 6, the material InGaAsP (indium gallium arsenide phosphide) of the upper waveguide layer 5, the lower waveguide layer 3 and the cover layer 2; the substrate layer 1 An example of a vertically coupled photodetector input front end of the material InP (Indium Phosphide).

[0028] First, some basic theoretical parameters of the front-end input waveguide structure of the waveguide coupler are listed:

[0029] waveguide material

InP

3.146

InGaAsP

3.33

InGaAs

3.56-0.1i

[0030] Table 1 Refractive index of various materials used in the detector;

[0031] Material of each layer

Thickness (μm)

Upper waveguide layer InGaAsP

3.5

Gap InP

0.09

Lower waveguide layer InGaAsP

3.05

Cladding InGaAsP

0.5

Substrate InP

15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com