Triggering ultrasonic tipping bucket rain gauge

An ultrasonic and rain gauge technology, applied in the field of ultrasonic rain gauges triggered by tipping buckets, can solve problems such as failures, increased equipment power consumption, and no rain sensor design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

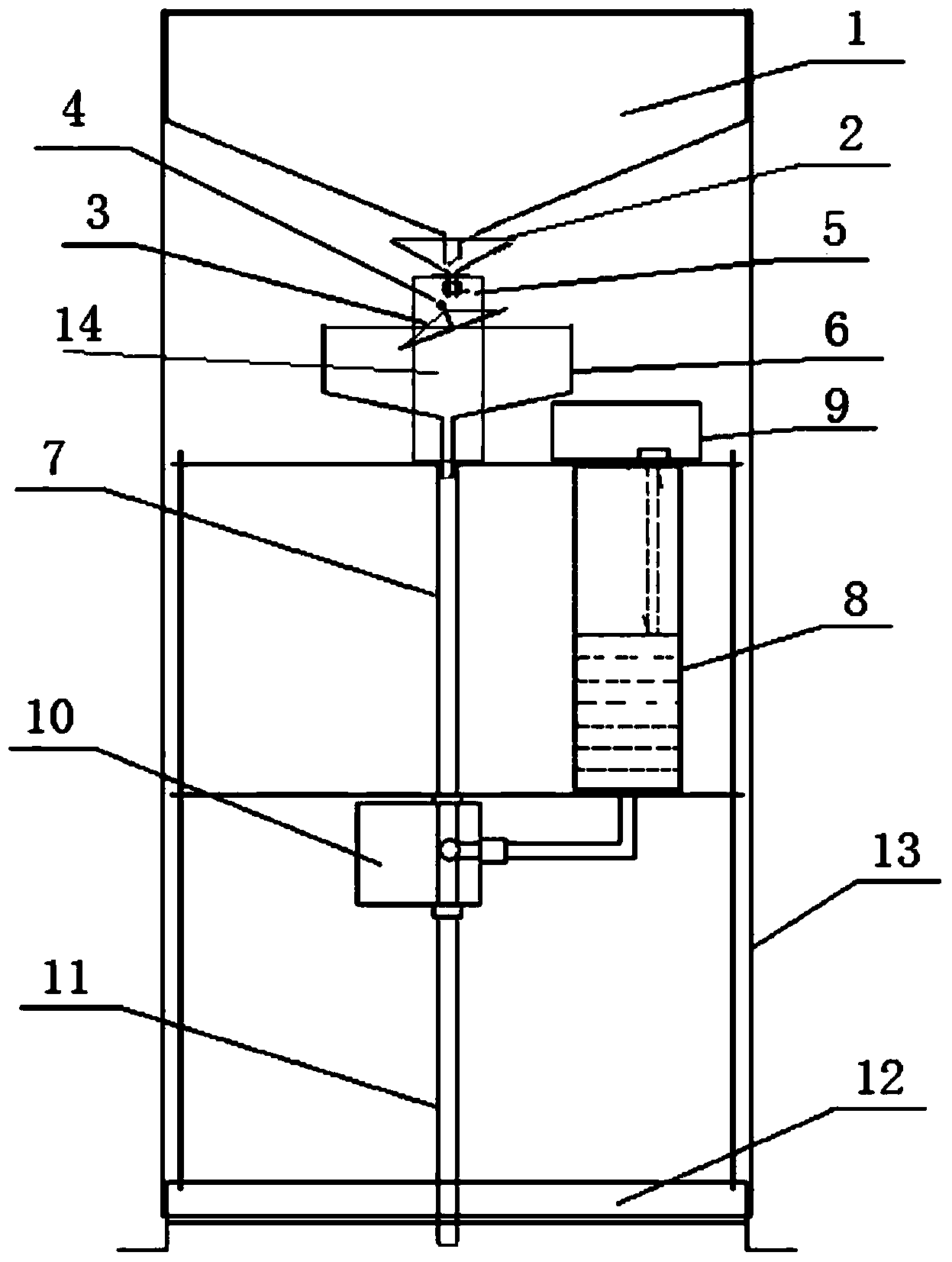

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the drawings and examples.

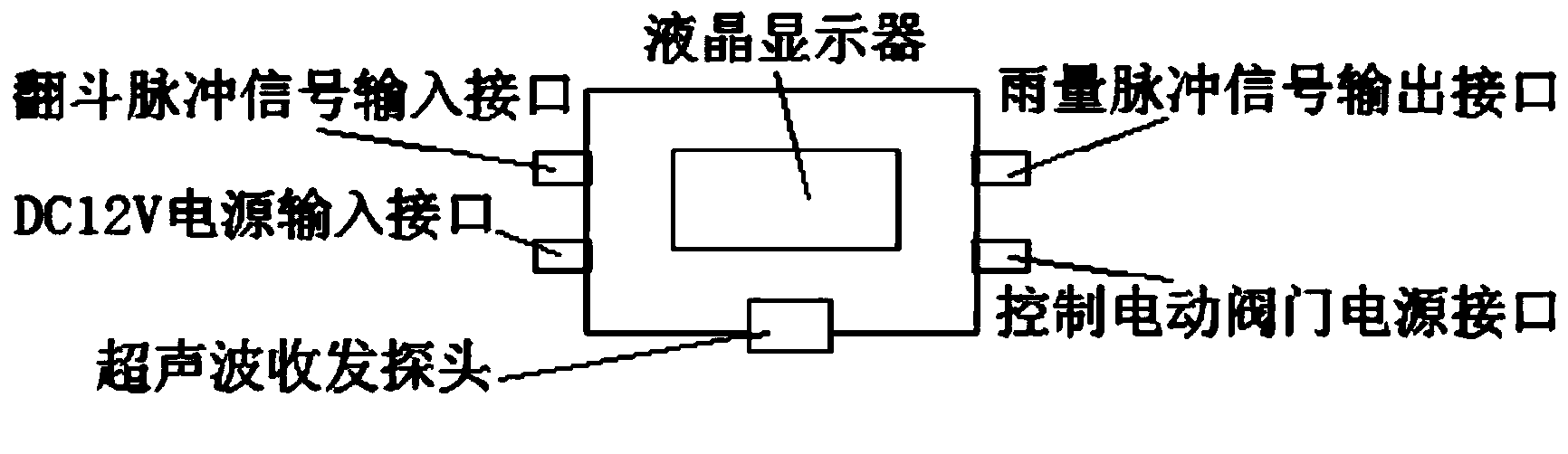

[0030] combine figure 1 , an ultrasonic rain gauge triggered by a tipping bucket proposed by the present invention, which includes a rain receiver (1), a funnel (2), a tipping bucket (3), a magnetic steel (4), a reed switch (5), and a bucket (6) , water inlet pipe (7), measuring cylinder (8), ultrasonic water level measurement controller (9), electric valve (10), water outlet pipe (11), base bracket (12) and outer barrel (13), wherein: in the same The rain receiver (1), funnel (2), tipping bucket (3) and bucket (6) are arranged in sequence from top to bottom on the axis, and the bottom end of the bucket (6) is connected to one end of the water inlet pipe (7) , the magnetic steel (4) is set on the top of the tipping bucket (3), the dry reed switch (5) is fixed above the side of the magnetic steel (4) of the tipping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com