Portable line fault monitoring/analyzing recorder

A line fault and recorder technology, which is applied in the field of analysis recorder, can solve the problems of low probability of manual successful detection of fault points, inability to fully meet the needs of fault diagnosis, poor contact of contactor contacts, etc., to achieve the purpose of recording voltage and current curves The effect of long time, easy connection of fault detection points, and short curve sampling period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

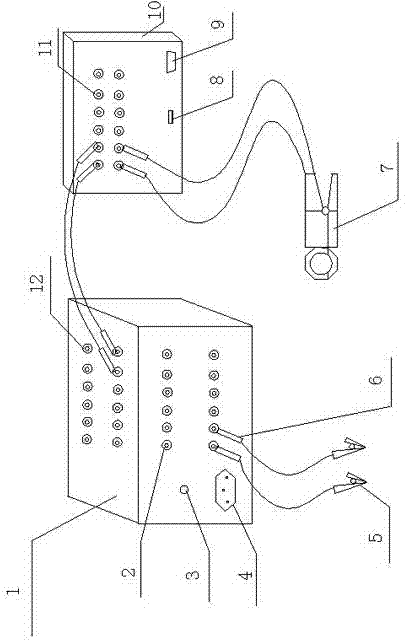

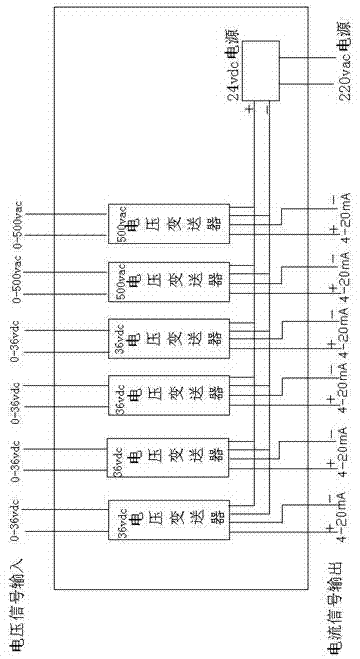

[0016] The invention is a portable line fault monitoring and analyzing recorder, which consists of a paperless recorder 10, a voltage conversion device 1, a clamp current transformer 7, connecting wires and the like. See the specific structure figure 1 , figure 2 .

[0017] See figure 1 , there are six signal input channels on the side of the voltage conversion device 1, and the input channels are respectively provided with input channel banana sockets 2. In this embodiment, each input channel is provided with a pair of input channel banana sockets 2, and the pair is two , including four DC voltage input channels between 0-36 volts, and two AC voltage input channels between 0-500 volts. There are six output channels corresponding to the input channels, and the six output channels are arranged on the voltage conversion device 1 . The output channels are provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com