High-speed dynamic compression test device

A technology of dynamic compression and test equipment, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of unstable equipment, limitation, damage, etc., and achieve the effect of simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

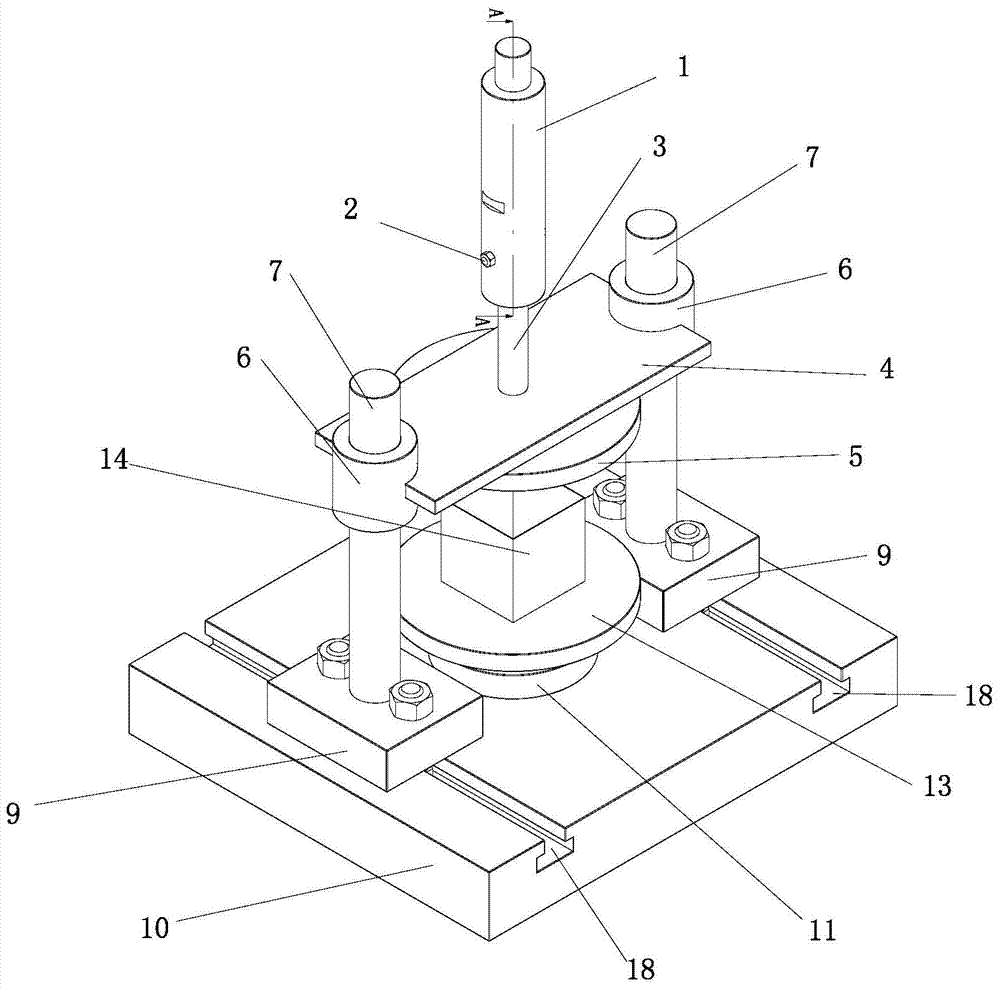

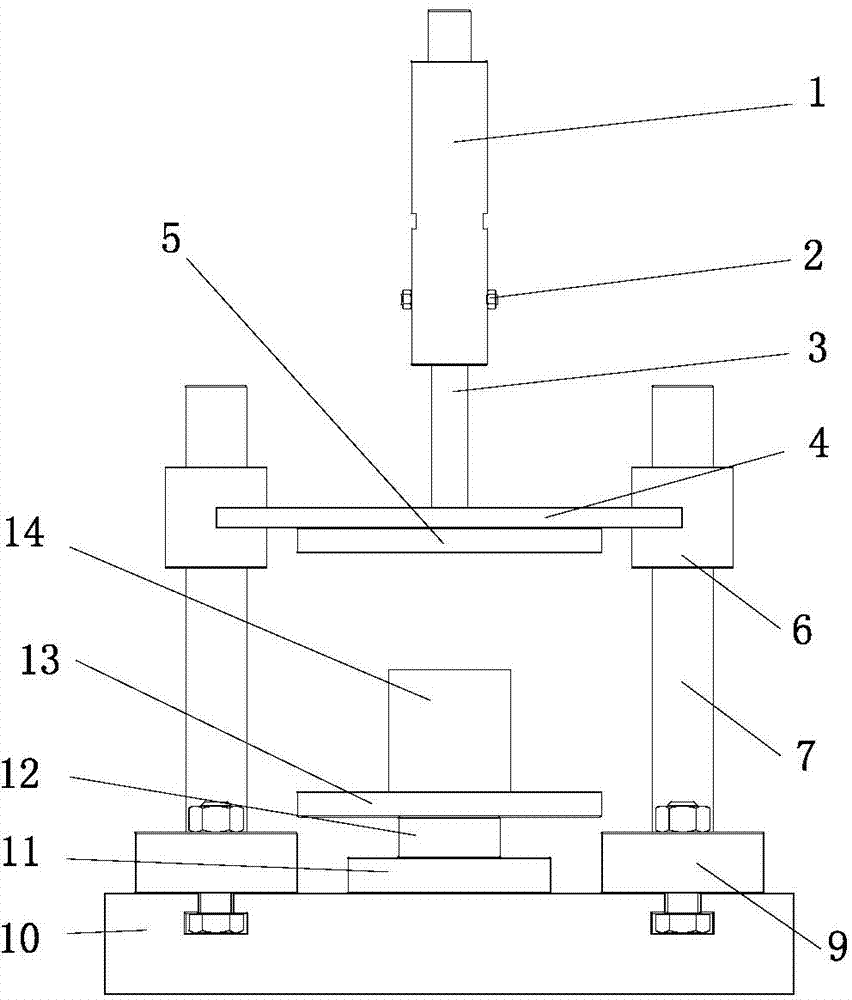

[0026] The present invention will be further described below in conjunction with accompanying drawing of description:

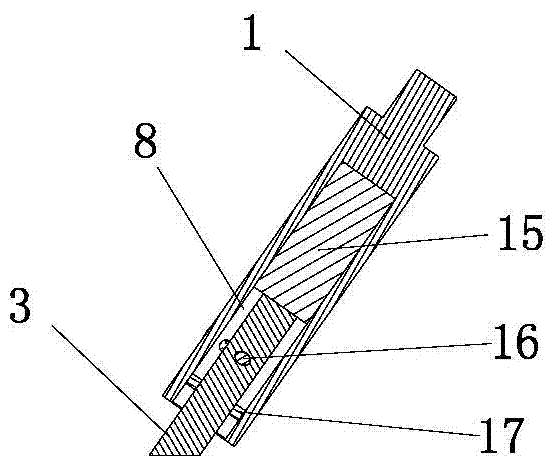

[0027] as attached Figure 1~5 As shown, a high-speed dynamic compression test device is used for a high-speed tensile testing machine, and the high-speed dynamic compression test device includes a mounting table 13 for installing a test piece 14 and a loading mechanism for compressively loading the test piece 14 , the loading mechanism includes a pressing plate 3 for compressing the test piece 14, a pressing rod 3 fixedly connected to the pressing plate 5 at one end, and a connecting rod 1 connected to the other end of the pressing rod 3 through an unloading rod 16, and the connecting rod 1 has a cavity 8 , the other end of the pressing rod 3 is located in the cavity 8 and the extension direction of the pressing rod 3 is the same as that of the connecting rod 1 .

[0028] The unloading rod 16 is arranged through the pressing rod 3 , and the two ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com