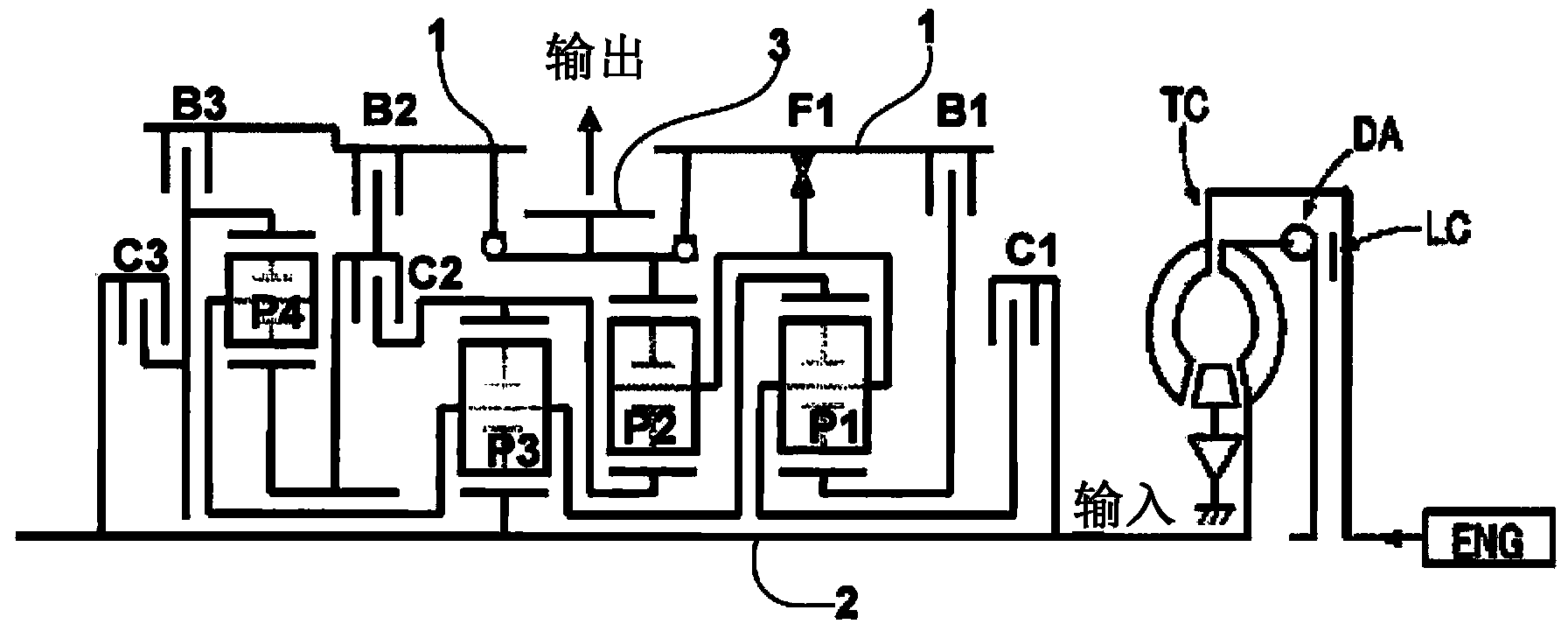

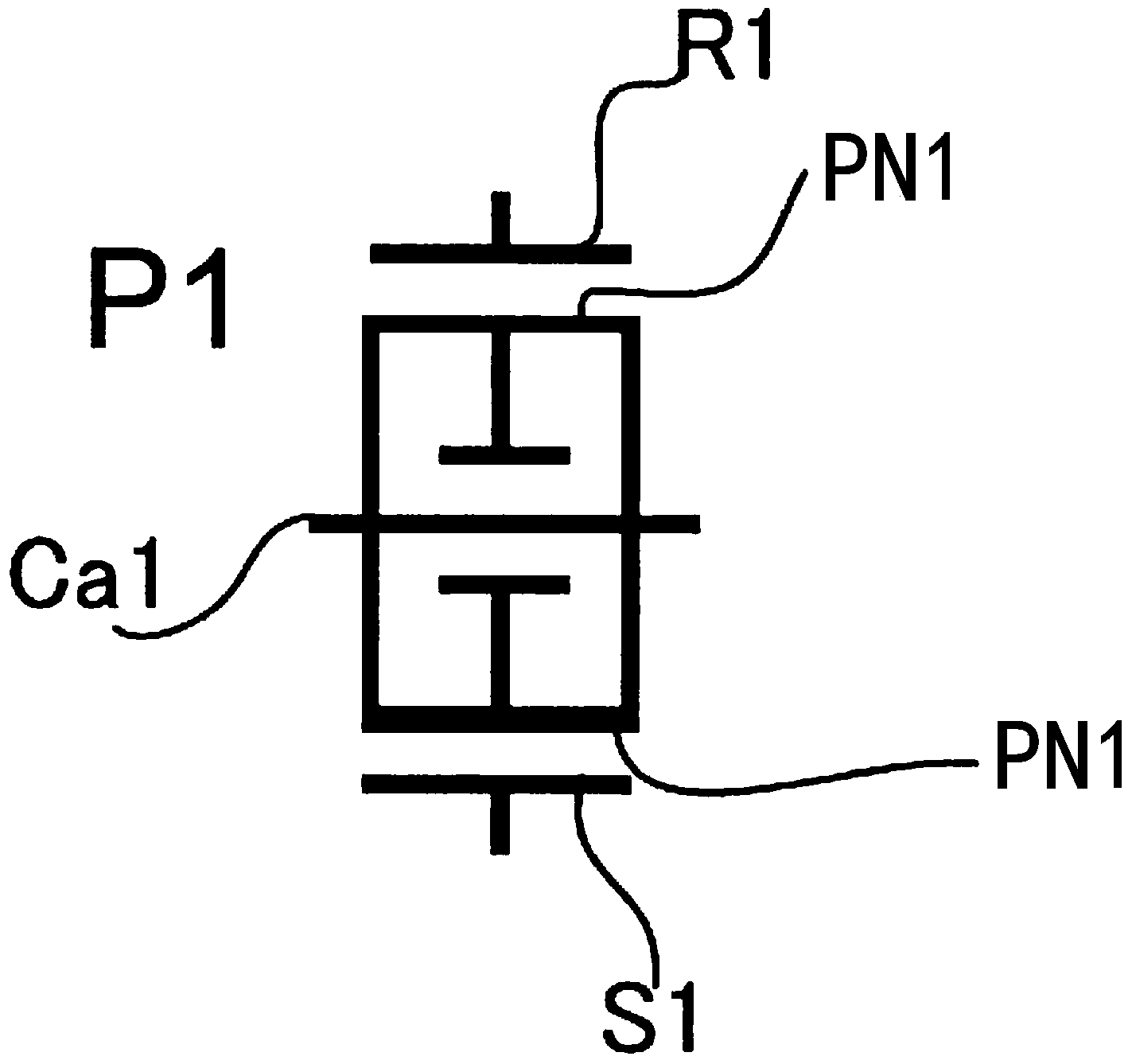

Automatic transmission controller

A technology for automatic transmissions and control devices, which is applied to transmissions, gear transmissions, transmission controls, etc., can solve problems such as cost issues, and achieve the effects of reducing weight, suppressing shifting shocks, and improving responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

[0133] Since the above-mentioned first embodiment includes the electric pump, the clutch and the brake can be hydraulically controlled by using the electric pump even when the engine is stopped. The second embodiment includes a pressure accumulator instead of the electric pump. The accumulator is a mechanical pressure accumulating device. When the engine is running, the oil pressure is stored in the accumulator tank, and it is maintained when the engine is idle and turned off. When it is restored, the accumulated oil pressure is taken out for use.

[0134] according to Figure 9B The control procedure of the following describes the control flow of the second embodiment. Step 30 , step 32 , step 42 , and step 44 are equivalent to checking that the condition of the idle stop control is satisfied. That is, when the engine is not stopped and the vehicle speed is greatly reduced without returning from the idle stop control, the process proceeds from step 44 to step 46, engages cl...

Deformed example 1

[0143] It also serves the purpose of filling ATF (ineffective filling) in the oil passage for recovery from idling cutoff, and enables early idling cutoff engagement (C2 / B2: engagement) at low vehicle speeds before stopping in D range.

[0144]

[0145] No oil pressure is supplied during idling cut-off, and when returning from idling cut-off control, the linear solenoid valve for C2 / B2 control is fully opened, and C2 / B2 is engaged immediately. Thereby, it is possible to reliably avoid backing up. That is, it is because the oil pressure of C2 / B2 is accumulated by a normal engine-driven oil pump.

Deformed example 2

[0147] In the second embodiment, at the time of return from idling stop, the return from idling stop determination signal is received, and the accumulated pressure is supplied to the linear solenoid valve for B1 pressure control in advance. This achieves the effect of speeding up the response time for shifting gears.

[0148] Therefore, in the case of returning from idling-off engagement, when the internal rotational speed of the transmission is almost 0 rpm during parking, the brake B1 can be engaged by fully opening the linear solenoid valve for brake B1 control, and the return from idling-off engagement can be performed. The spindle speed remains at 0.

[0149]

[0150] In the second embodiment, as in the first embodiment, the transition from the idle stop engagement to the first speed is performed by switching C2 and B1 while the brake B2 is engaged. At this time, the pressure of the clutch C2 remains in a non-backward manner, and when the pressure of the brake B1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com