Novel heat insulation and sound insulation building door and window profile

A technology for thermal insulation, sound insulation, and building doors and windows, which is applied in the direction of buildings, building components, and building structures. It can solve the problems of high price, complex processing, and weak material integrity, and achieve low cost, convenient processing and molding, and is conducive to batch production. The effect of chemical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

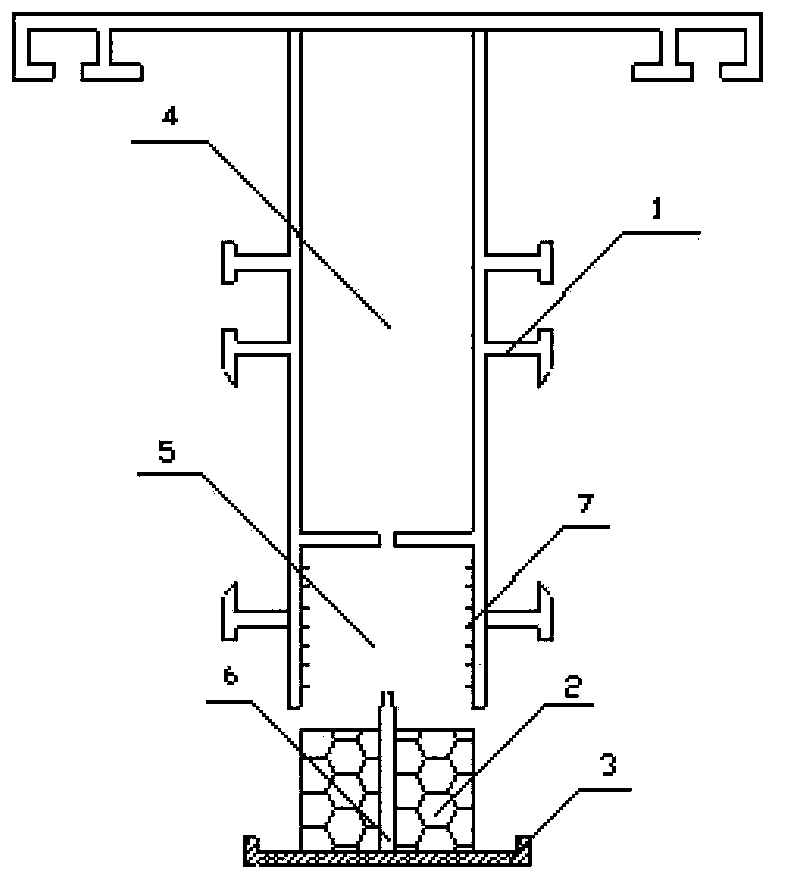

[0013] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0014] As shown in the figure: a new type of thermal insulation and sound insulation building door and window profile, which is characterized in that it includes an aluminum alloy fixed support frame 1, an insulation layer 2 and an interior decoration layer 3, the aluminum alloy fixed support frame 1 is located outdoors, and the aluminum alloy fixed support frame 1 is located outdoors. The outer layer of the cross section of the fixed support frame 1 is the outer layer inner cavity 4, the inner layer is the inner layer inner cavity 5, the thermal insulation layer 2 is embedded in the inner layer inner cavity 4, the interior decoration layer 3 is located indoors, and the interior decoration The layer 3 is provided with screws 6, and the screws 6 connect the insulation layer 2 and the aluminum alloy fixed support frame 1. The inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com