Cylindrical tension and compression support for transferring upper load to lower part or pier foundation

A load transfer, cylindrical technology, applied in the direction of bridge parts, bridges, buildings, etc., can solve the problems that cannot satisfy the free rotation and horizontal displacement of the support, and the increase of structural load, etc., achieve simple structure, avoid bending internal force, and reduce manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

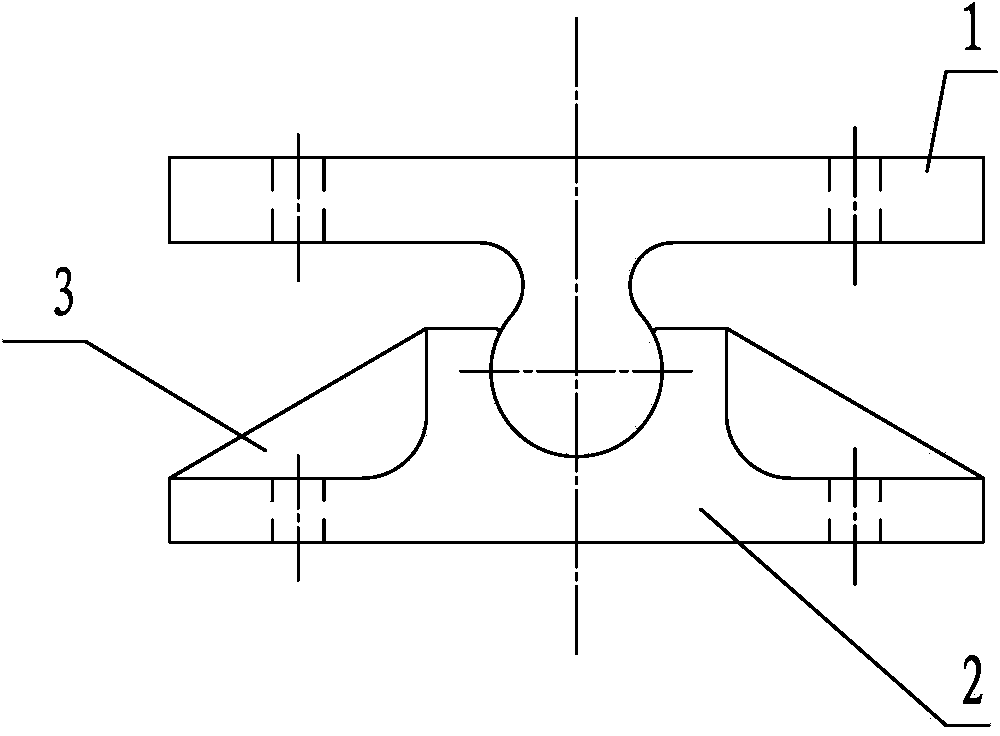

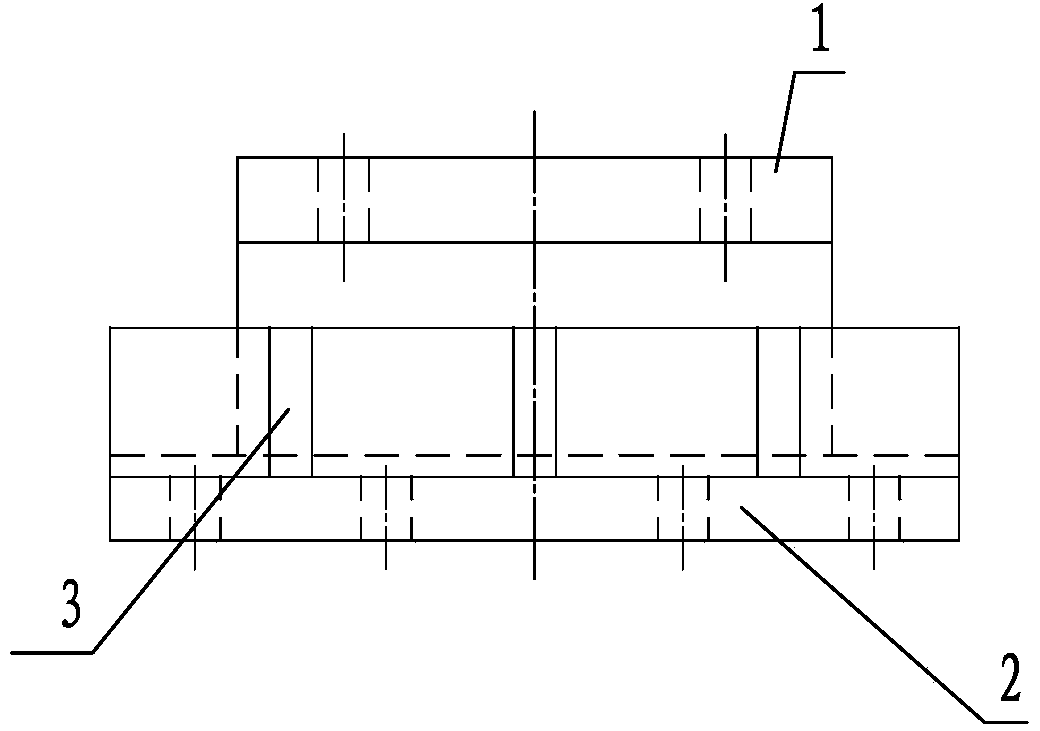

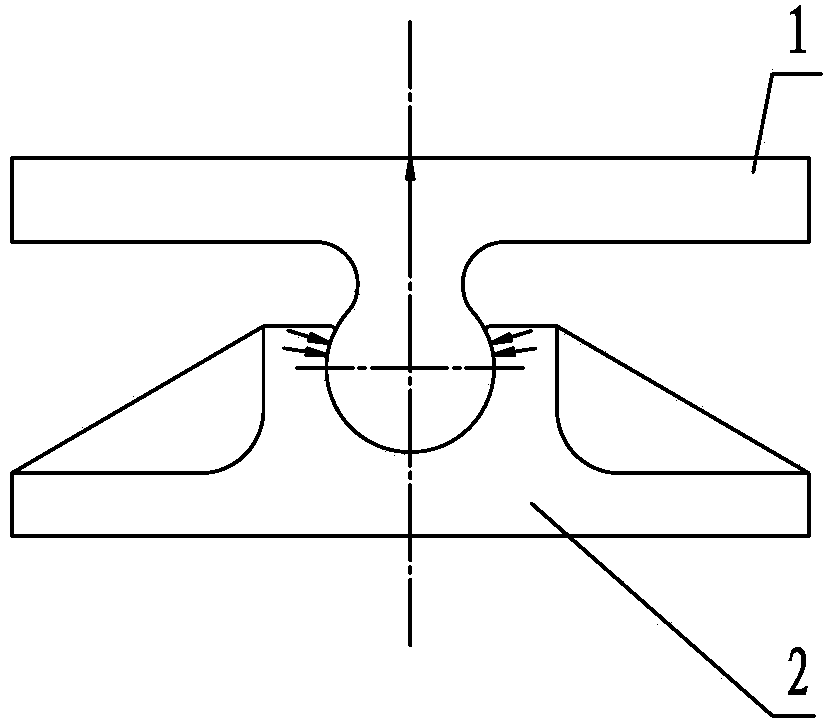

[0014] refer to figure 1 , 2 , the present invention has a support upper pendulum part 1 and a support lower pendulum part 2. The support upper pendulum part and the support lower pendulum part respectively have bolt holes connected with the main structure. connected to the structure directly, or connected to the structure by welding or other means. The upper part of the upper part of the upper part of the support is rectangular or circular, and the lower part of the upper part is incomplete cylindrical 4. The incomplete cylindrical shape is connected with the upper part of the upper part in an arc shape, and there is an incomplete cylindrical part in the middle of the lower part of the support. It is a cylindrical groove free to rotate or slide horizontally, and a local stiffener 3 is arranged on the hem part of the support.

[0015] The radius of the incomplete cylinder 4 is determined by the bearing capacity of the support. The radius of the incomplete cylinder 4 is 50-10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com