Plasma spraying execution system

An execution system and plasma technology, applied in coating, fusion spraying, metal material coating process, etc., can solve the problems of inconvenient, fast control, poor control sensitivity, low safety performance, etc., and achieve high device safety performance, The effect of quick spraying processing and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

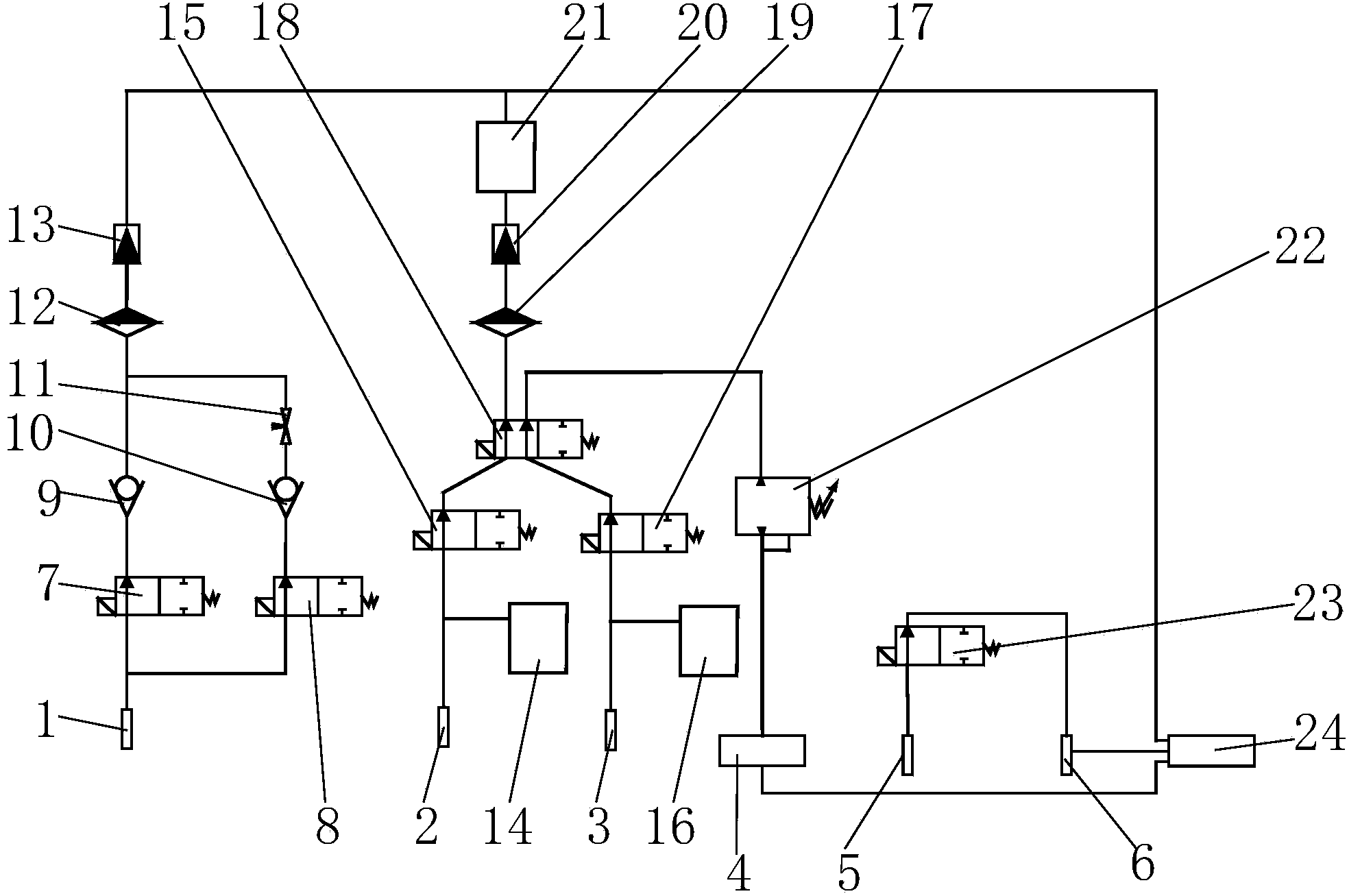

[0014] like figure 1 As shown, a plasma spraying execution system includes an ignition gas channel, a main gas channel, a powder feeding channel, an air channel and a spray gun 24, and the ignition gas channel is connected to the spray gun 24 after merging with the main gas channel. The main air channel and the powder feeding channel are connected through pipelines and merged into the spray gun 24, and the air channel is connected to the spray gun 24. The gas that feeds in the ignition gas channel is hydrogen, provides fuel gas when the spray gun 24 is ignited, and closes automatically after the spray gun 24 ignites; Oxidation of the spraying material; after the ignition gas channel delivers hydrogen to the spray gun 24 for ignition, the ignition gas channel is closed, the main gas cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com