Composite modificator improving wear performance of copper-zinc-aluminum memory alloy in alkaline medium

A technology of compound modifier and memory alloy, which is applied in the field of copper-based memory alloy, can solve problems such as the stabilization of coarse grained martensite, limit the application range, and affect wear resistance, so as to optimize the structure, purify the alloy liquid, and improve The effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

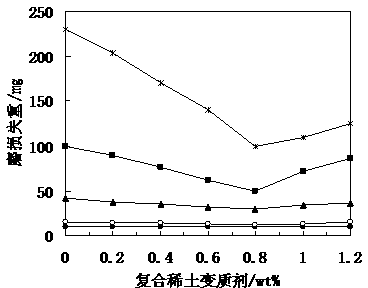

[0008] Using Zn25 wt %, Al4 wt %, and copper as raw materials, it was weighed and then smelted in an intermediate frequency induction melting furnace. The smelting process is as follows: add electrolytic copper, zinc ingots, and aluminum ingots. After the materials are completely melted, when the temperature rises to 1240 ° C ~ 1260 ° C, the compound rare earth modifier is added by the flushing method. The amount of the compound modifier is 0.2wt% ~ 1.2wt %. Pouring into an ingot with a diameter of φ80×150mm. The annealing treatment is heating to 850°C for 24 hours and then cooling with the furnace, then turning to remove the 2-3mm dezincification layer on the surface, and then forging the ingot at 850°C for 30 minutes to form a φ55×60mm bar. Finally, heat treatment is carried out, and the specific process is as follows: after 30 minutes of heat preservation at 850 ° C, it is taken out from the heat preservation furnace and cooled under atmospheric conditions. Sampling is do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com